Reasons Why 3D Printing Technology is Underrated

Reasons Why Additive Manufacturing is a Superior Form of Manufacturing

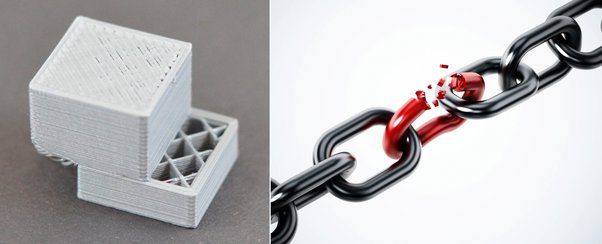

Additive manufacturing is the technique of production that 3D printers use to create physical objects. Additive manufacturing is the manufacturing process in which you create an object from scratch by directly layering the raw material.

This technique is different from others because it does not create waste like subtractive manufacturing. It does not require manual effort and time like the formation process where you add force to a material to shape it, and it does not require tools and molds like casting to produce a functional product.

In conclusion, additive manufacturing requires no tools, has no waste, and needs zero cutting and complex procedures.

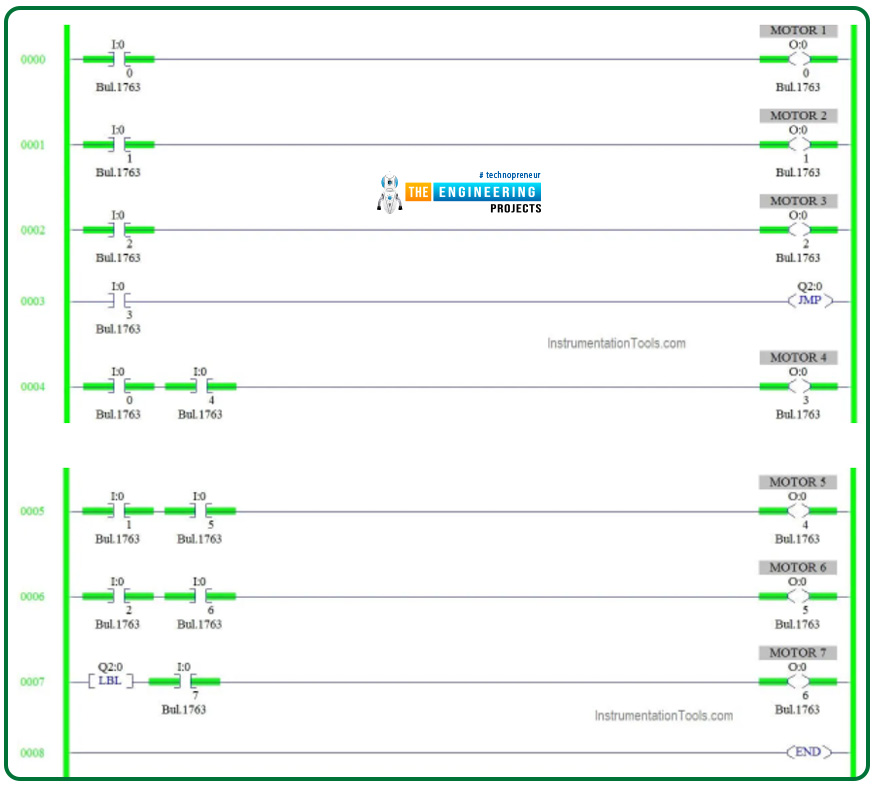

How Does Additive Manufacturing Work?

There are various types of additive manufacturing in the market. All of these processes are suitable for their respective fields and functions. A production house can use one of these techniques to create its design.

Direct Casting

After the design is complete, cure the product in an oven to enhance its mechanical properties. The cast of the product comprises a water-breakable mixture. Therefore, in the third step, soak the mold in water. It will degenerate, and you can finish your product in the last step for further use.

This process is rapid, and your production, which took weeks, now only takes a few days.

FDM

Fusion deposition modeling is a typical process of manufacturing in an additive process. A domestic printer uses this process to create designs. This printer is easy to use as you need to fill the printer with filament from one end, and it will produce your design on the other end.

This process needs a design, the software cuts the design into thin digital slices, and once the data is in the printer, it will create the product automatically. It may be easy to use, but large-scale industries do not prefer it for its poor finish and fragile material.

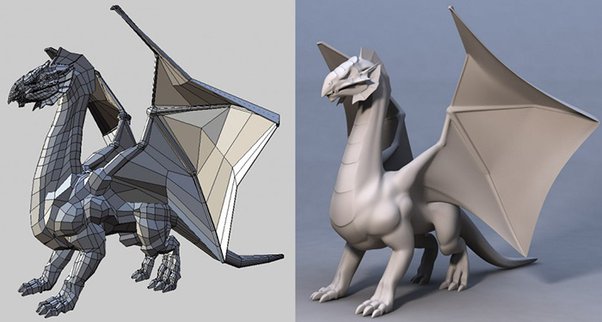

SLA Printing

The process of Stereolithography is unique as it uses photosensitive resin to solidify the design out of liquid polymer. It is a precise way of creating objects from resin, and it does not require as much time as other printing methods. The UV rays cure the liquid polymer on top of the layers. It creates an illusion of an object being born from the liquid.

Laser Sintering

The laser sintering method is dangerous in public places, but it is practical for enormous industries. It uses refined metal powder as raw material. The machine uses a laser to create a solid object from this metal dust. The printer does have a container box for metal powder but inhaling this powder can be dangerous.

NASA and other mechanical corporations use this technique to build parts for air crafts, planes, cars, and other automobiles. If the production house follows all the SOPs, this method is one of the fastest methods of creating parts.

Poly Jet Method

The poly jet method is a mixture of FDM and SLA printing. The machine uses thin layers of resin and layers are like a filament, and the UV light instantly cures the resin in place. This technique is valuable for rapid prototyping, fixtures, and creating functional moving parts.

The Revolutionary Implications of 3D Printing

Multiple applications and implications of 3D printing suggest that it has revolutionized the world. 3D printing has minimized the connection between production and consumption. A consumer can directly produce a design in a short time. The time for a product to reach the consumer has drastically reduced.

The emergency disaster zone fixtures are possible with the help of instant 3D printing. It also inspires the younger generation to create and practically use their theoretical knowledge. It has inspired the world to connect virtual reality to physical reality. And all of this is just the beginning of what 3D technology has to offer.