Hey fellow! Welcome to the next article on the MQ series of sensors, and today our focus is on the MQ-8 which is used to sense the presence of hydrogen gas. We know that hydrogen is a colorless, odorless, and tasteless gas that humans can not sense easily. It is not toxic like carbon monoxide and other such examples but still, the excess presence of this gas can be life-threatening because it is highly flammable. The air is a mixture of different gases and hydrogen gas when combined with some specific gases, can be harmful to life. In the presence of a bare flame or other ignition material, hydrogen can start the ignition, and here, the duty of sensors like MQ-8 starts. We’ll examine the basic information about this sensor in detail.

In this article, we’ll start reading about the basic introduction to the MQ-7 hydrogen gas sensor. We’ll see the basic data sheet, specifications, features, and core information about this product. After that, we’ll move on to this work in detail and understand its structure to analyze its output. We’ll end this chapter with the physical dimensions and the applications of this sensor in different domains of life. There are many things to learn here so let’s move towards the first topic:

MQ-8 Hydrogen Gas Sensor Introduction

The MQ-8 is a specialized sensor mainly designed to sense the surplus amount of hydrogen gas that can be harmful to people with sensitive lungs because excess inhalation of hydrogen can displace the oxygen atoms in the lungs. Moreover, it may be inflammable in the factories or industries using the particular material.

For some materials, the hydrogen gas can be the cause of brittleness and even cracks therefore, is a harmful gas for materials like storage tanks and pipelines. In such areas, the sensors like MQ-8 are used to detect the presence of any hydrogen gas leakage. The structure is designed in such a way that as soon as the surplus amount of hydrogen is sensed in the environment, it sends the signal through the analog and digital pins to the output devices for indication.

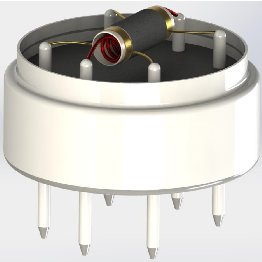

Here are the basic parts of the MQ-8 hydrogen sensor:

MQ-8 Hydrogen Gas Sensor Sensing Element

The heart of this sensor is the sensing element that lies on the base of a circuit that continuously heats it. This element is made of ceramic material that has a layer of tin dioxide (SnO2) on it. This layer is responsible for absorbing the high concentration of hydrogen gas in the surroundings as a result, the sensor can indicate its presence.

MQ-8 Hydrogen Gas Sensor Heater

A heater circuit is present in the core of this sensor which is a heater coil that is wrapped around the sensing element and continuously heat it. This circuit is always on and this constant heating is crucial for the accuracy of the sensor performance.

MQ-8 Hydrogen Gas Sensor Electrodes

Two electrodes are connected to the sensing element that is responsible for working according to changes in the circuit resistance. This resistance depends on the ion formation reaction on the sensitive element.

MQ-8 Hydrogen Gas Sensor Filter

A stainless steel mesh network is present on the whole circuit that consists of two layers. These layers are responsible for the following tasks:

Protection of the internal element from the outward unwanted particles. It simply allows the gases to pass through it to filter the articles.

Helps the internal structure to retain its position.

Moreover, it has pins, voltage regulators, filtering capacitors, and pre-heat resistors that support the smooth performance of the MQ-8 hydrogen gas filter.

MQ-8 Hydrogen Gas Sensor Datasheet

Let us discuss some important parts of the datasheet that will help you understand the product details. We’ll are making a start with its features:

MQ-8 Hydrogen Gas Features

It is a sensitive detector and its range is between 100 to 10,000 PPM where the PP means the parts per million.

It can sense the small leakage of hydrogen gas and, therefore, is considered a reliable sensor.

The structure is designed in such a way that it detects the hydrogen gas accurately even in the presence of other gases such as methane, ethanol, and carbon monoxide. As a result, the sensor does not provide the false alarms.

This sensor shows a fast response time that ranges between 30 seconds to 100 seconds after it is powered on.

It has a simple and small circuit that does not consume a lot of energy. Moreover, the easy circuit makes it less costly.

Another advantage of a simple circuit is its long life. Moreover, it is a lightweight device.

MQ-8 Hydrogen Gas Sensor Specifications

Here is a table of the specifications for the MQ-8 hydrogen gas sensor:

Parameter |

Value |

Units |

Model |

MQ-8 |

N/A |

Sensor Type |

Semiconductor |

N/A |

Standard Encapsulation |

Bakelite, Metal cap |

N/A |

Target Gas |

Hydrogen |

N/A |

Detection range |

100 – 1000 |

ppm |

Loop Voltage (Vc) |

≤ 24 |

VDC |

Heater Voltage (VH) |

5.0 ± 0.1 |

VDC or AC |

Load Resistance (RL) |

Adjustable |

N/A |

Heater Resistance (RH) |

29 ± 3 |

Ω |

Heater Consumption (PH) |

≤ 900 |

mW |

Sensitivity (SRs) |

≥ 5 |

N/A |

Output Voltage (Vs) |

2.5 – 4.0 |

VDC |

Concentration Slope (α) |

≤ 0.6 |

(R1000ppm/R400ppm H2) |

Temperature & Humidity |

20 ± 2°C; 55 ± 5% RH |

N/A |

Vc |

5.0 ± 0.1 |

VDC |

VH |

5.0 ± 0.1 |

VDC |

Preheat Time |

Over 48 |

hours |

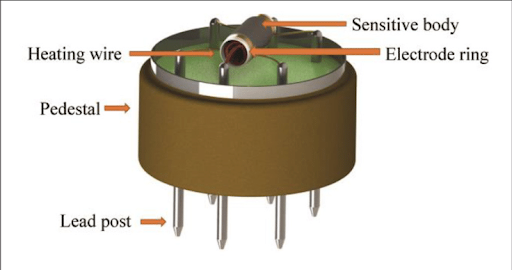

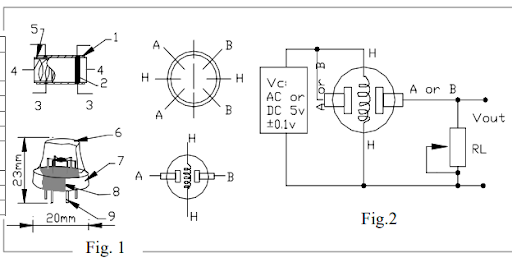

MQ-8 Hydrogen Gas Sensor Internal Structure

The internal structure of this sensor is simple as discussed before in the previous section. Here is the diagram that will explain the internal circuit and its basic labeling:

This diagram will be understood by using the detail of each label as mentioned below:

Gas Sensing Layer (SnO2):

SnO2 material used for gas sensing.

Electrode (Au):

Electrode made of gold (Au).

Electrode Line (Pt):

Electrode line composed of platinum (Pt).

Heater Coil (Ni-Cr Alloy):

Heater coil material: Nickel-chromium alloy (Ni-Cr).

Tubular Ceramic (Al2O3):

Tubular ceramic material: Aluminum Oxide (Al2O3).

Anti-explosion Network:

Stainless steel gauze (SUS316 100-mesh) is used as an anti-explosion network.

Clamp Ring (Copper Plating Ni):

Clamp ring made of copper with nickel plating.

Resin Base (Bakelite):

Resin base material: Bakelite.

Tube Pin (Copper Plating Ni):

Tube pin made of copper with nickel plating.

If you want to know more about the datasheet then you can visit the link given below:

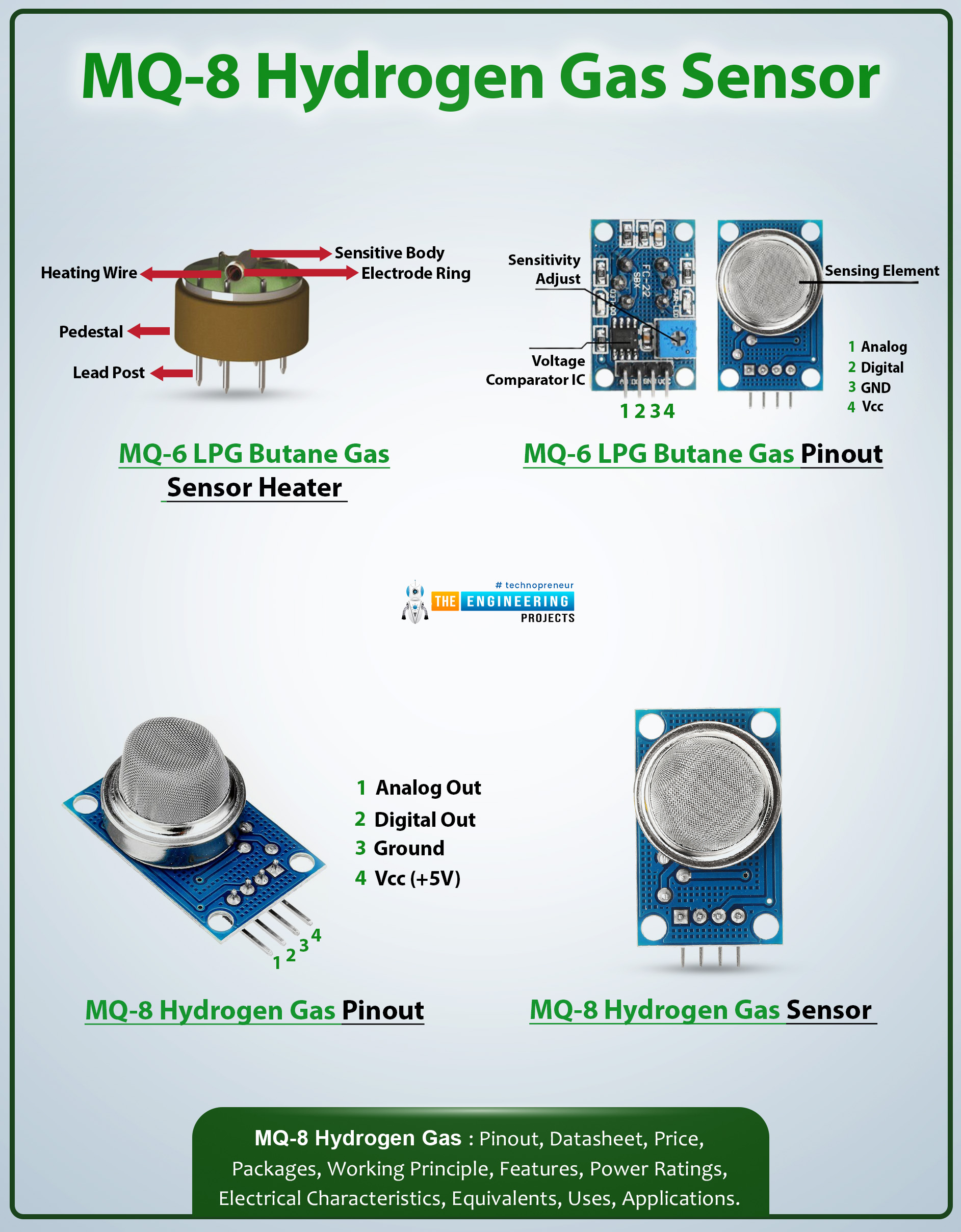

MQ-8 Hydrogen Gas Sensor Pinout Configuration

As with all members of the MQ series, the MQ-8 hydrogen gas sensor has four pins and in some models, an additional pin is also present. Here is the table that shows the pin number, its name, and a brief description:

Pin Name |

Function |

Description |

VCC |

Power Supply |

This pin provides power to the sensor, typically 5V DC. |

GND |

Ground |

It connects the sensor to the ground for proper circuit operation. |

DOUT (Digital Output) |

Digital Output |

This pin provides a digital signal indicating the presence or absence of hydrogen gas. |

- Clean Air |

HIGH (≈5V) |

This value on the digital pin shows no hydrogen gas detected. |

- Presence of H2 Gas |

LOW (≈0V) |

This value on the digital pin shows hydrogen gas detected. |

AOUT (Analog Output) |

Analog Output |

This pin provides an analog voltage signal that varies with hydrogen gas concentration. |

- Low Concentration |

Low voltage (specific value depends on sensor model) |

N/A |

- High Concentration |

High voltage (specific value depends on sensor model) |

N/A |

MQ-8 Hydrogen Gas Sensor Packages

For the convenience of the user, manufacturers present different types of packages for the MQ sensors. Here is the table that explains the SMD and DIP package of the MQ-8 hydrogen gas sensor:

Feature |

SMD Package |

DIP Package |

Package Type |

Surface Mount Device |

Dual In-Line Package |

Dimensions |

It varies depending on the manufacturer, but common sizes include:

|

Typically 38mm x 20mm x 14mm |

Mounting |

It is designed for the soldering onto PCB pads |

It is designed to Insertion into sockets |

Terminals |

It usually 4 pins (VCC, GND, DOUT, AOUT), some models may have additional pins |

It typically 4 pins (VCC, GND, DOUT, AOUT) |

Material |

Ceramic or phenolic resin housing |

Ceramic or plastic housing |

Weight |

Approximately 2-3 grams |

Approximately 4-5 grams |

Operating Temperature |

-20°C to +70°C (typical) |

-20°C to +70°C (typical) |

Storage Temperature |

-40°C to +85°C (typical) |

-40°C to +85°C (typical) |

Humidity Range |

10% to 95% RH (non-condensing) |

10% to 95% RH (non-condensing) |

Cost |

Generally lower |

Generally slightly higher |

Assembly |

Requires soldering |

No soldering required |

Suitability |

Space-constrained designs, mass production |

Hobbyist projects, prototyping, easier handling |

Where to Buy MQ-8 Hydrogen Gas Sensor?

there are multiple options to buy such products online but the most trusted ones are listed below:

eBay

AliExpress

Amazon

MQ-8 Hydrogen Gas Sensor Working Principle

If you've followed the details about the sensor's structure in the previous section, understanding how the MQ-8 hydrogen sensor works should be straightforward. Here are the steps that show the working principle in this regard:

As soon as the sensor is powered on, the heating circuit starts its duty. In 20 to 100 seconds, it starts heating the sensing element.

The heating process stimulates the tin oxide to absorb the oxygen gas from the surroundings. This created a depletion region consisting of hydrogen ions around the tubular-shaped tin oxide.

Soon, the depletion region is strong enough to enhance the resistance of the circuit. At this point, the MQ-8 hydrogen sensor is ready to sense the pure hydrogen gas in the environment.

In the case when there is a leakage of the hydrogen gas, the sensing element starts reacting with it.

If there is a notable amount of hydrogen in the environment, the depletion region around the sensing element starts resting with it. As a result, the resistance of the circuit starts decreasing.

The values of the electrical current passing through the circuit increase and eventually, the analogue values are sent to the output device through the analogue pin.

By the same token, the digital pin is stimulated when a particular analogue value is crossed.

These signals are then sent to the output device. Usually, the projects are made using any microcontroller or other such devices.

MQ-8 Hydrogen Gas Sensor Physical Dimensions

The physical dimensions of such products vary from model to model. I‘ve created a general table that shows the dimensions of the MQ-8 hydrogen gas sensor mentioned here:

Dimension |

Value (mm) |

Range (mm) |

Length |

33 |

32 - 35 |

Width |

21 |

20 - 22 |

Height |

13 |

11 - 15 |

Weight |

7 |

N/A |

Shape |

Rectangular with rounded corners |

N/A |

Pin configuration |

4 or 5 (model dependent) |

N/A |

Mounting holes |

2 (sides) |

N/A |

MQ-8 Hydrogen Gas Sensor Applications

Hydrogen gas is not toxic and it is less commonly used as compared to the other gases therefore, it is not widely used in household applications but it is used in the areas where large amount of hydrogen is used. Here is the list of examples of some applications:

Industrial hydrogen gas monitoring

Hydrogen gas leakage detection

Fuel cell applications

Hydrogen-powered vehicle safety

Chemical processing environments

Laboratory gas detection

Hydrogen storage facilities

Aerospace industry applications

Hydrogen fuel production and storage

Energy-related processes

Today, we learned a lot about the MQ-8 hydrogen gas sensor. We initiated the discussion through the introduction of this sensor where we discussed its basic parts. Following that, we moved into the datasheet, uncovering a trove of information encompassing features, specifications, and the sensor's internal architecture. Progressing further, we unveiled the intricacies of its working principle, concluding our exploration with a glimpse into the diverse applications harnessing the potential of this sensor. If you crave more knowledge, stick around for our forthcoming insights.

Embedded Sensors

Embedded Sensors xeohacker

xeohacker 0 Comments

0 Comments