Hi readers! I hope you are doing well and finding something new. Today the topic to be discussed is – Types of metal 3D Printing. Metal 3D printing is a modern method of manufacturing in which solid metal parts are built up from a succession of thin metal layers of powder, wire, or sheet materials.

It has been widely used in aerospace, medical, automobile, and construction parts like this aerospace bracket, which is an implant customized for a particular patient, and high-performance automobile components. Metal 3D printing is not a subtractive manufacturing process and brings no waste of the material during the production process while it gives the designer full design control.

Among those key technologies are Powder Bed Fusion, or PBF, which fuses metal powder using lasers or electron beams for parts of the highest precision, and Directed Energy Deposition, or DED, which creates and fuses material simultaneously and is suited for very large components and repairs. Binder Jetting offers affordable and high-speed production of non-load-bearing parts, and Bound Powder Extrusion and Sheet Lamination comprise methods good for entry-level applications and prototypes. Both methods serve particular purposes in terms of precision, material suitability, and viability making the metal 3D printing an essential technology within the existing manufacturing industry.

Here in this article, you will learn various diverse forms of metal 3D printing.

Let’s dive into the details.

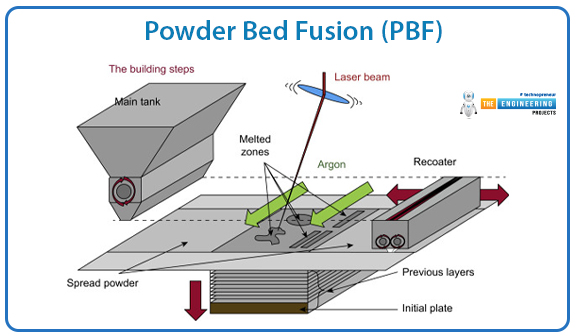

Powder Bed Fusion (PBF):

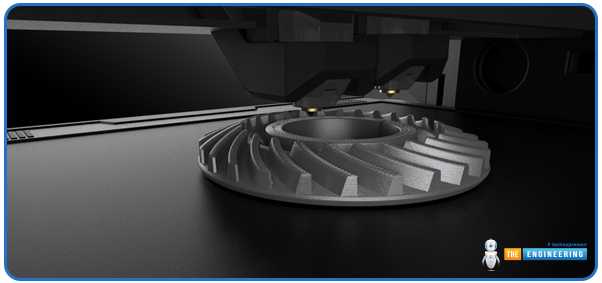

Powder Bed Fusion (PBF) is one of the most common metal-added manufacturing processes which allows for top accuracy and great flexibility, the components produced are of extremely high strength. In its work, it employs a concept often referred to as spreading the metal powder and creating layers on the build platform. This process utilizes a source of heat such as a laser or electron beam. In SLM and PBF, it is a method of selective melting and sintering the layer by layer of a powder bed.

This technique, because of the formation of highly intricate geometries, has huge utility across several sectors including aerospace, automotive, and health.

Variants of PBF:

This variant uses a high-powered laser to fully melt metal powder, layer by layer. SLM produces parts with excellent mechanical properties comparable to forged metals. It is utilized particularly in all high-performance industries like aerospace for cases and medical for fixtures.

Direct Metal Laser Sintering (DMLS):

DMLS also shares many similarities with SLM but instead of the material being melted and bonded, the particles are sintered, or partially melted to ‘weld’. It is ideal for creating designs with high geometric density and microstructures from alloyed metals.

Electron Beam Melting (EBM):

As a heat source, EBM makes use of electron beam irradiation, accelerated in a vacuum to avoid surface oxidation. It excels with reactive metals such as titanium and nickel alloys, often used in aerospace components and biocompatible medical implants.

Advantages:

Excellent precision and fine details.

High mechanical strength and density.

Supports intricate designs and lattice structures.

Limitations:

High costs for equipment and materials.

It is post-processed rigorously, to have finishing and support removal on its surface.

It cannot exceed the dimension of a build by a powder bed size.

PBF keeps manufacturing developing; there will never be designs without their intended functions.

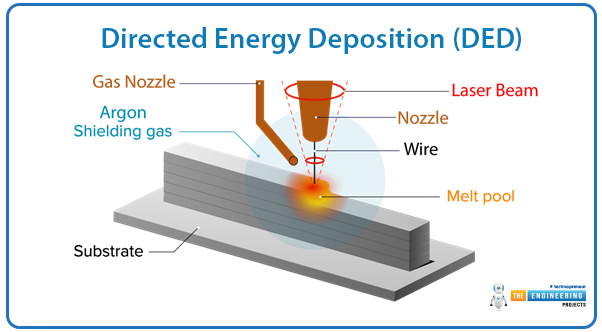

Directed Energy Deposition (DED):

Directed Energy Deposition is an open-platform metal 3D print-based technology where a metal stream is melted at the same time through a heat source such as a laser, an electron beam, or a plasma arc. It can be opted for in large component production, in the repair of parts that have been affected by elements, and in the strengthening of structures.

Process Description:

The metal material is fed through the nozzle of the feeder, and it's in the form of powder or wire. During the deposition of the material, the layers are melted using an energy source. Unlike Powder Bed Fusion, DED employs multi-axis motion systems, by which complicated geometries can be created and there is an opportunity to make repairs on pre-existing components.

Applications:

Repair and Maintenance: It is typically applied for repairing worn-out parts in aerospace, defense, and heavy machinery.

Massive Production: This is suitable for large-sized parts that cannot be accommodated in a powder bed.

Cladding: Applying surface-to-protection layers or functionalities to extend the service life of the part.

Benefits:

High Deposition Rates: It can produce faster than most of the other 3D printing technologies.

Material Versatility: It can be used with many types of metals, including titanium, steel, and nickel alloys.

Part Repair: It is an excellent option to repair expensive or critical parts.

Limitations:

Lower Resolution: Parts may not have the finer detail possible in Powder Bed Fusion.

Post-processing: Required as surfaces are mostly machined for smoothness to precise dimensions.

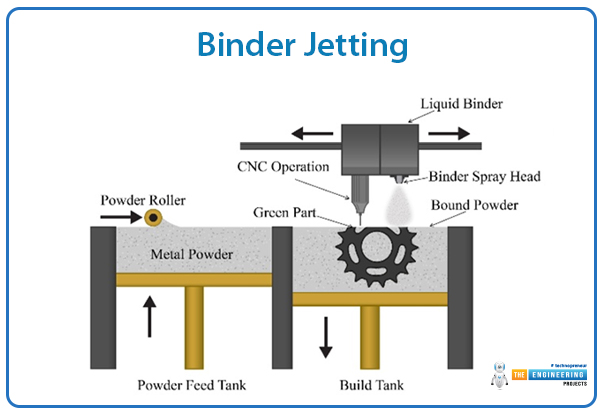

Binder Jetting:

Binder Jetting is a fast and low-cost metal 3D printing process for building parts by bonding together layers of metal powder with a liquid binding agent. In contrast to direct-fusion-based methods, Binder Jetting generates a "green part," which then needs post-processing to reach its final strength and density.

Process Steps:

A thin layer of metal powder is spread evenly across the build platform.

A print head selectively deposits a binder to bond particles in defined regions.

The process is repeated layer upon layer until the part is fully formed.

The "green part" is removed and post-processed through processes like sintering or infiltration by another metal for increased property

Applications:

Prototypes and Decorative Parts: The part has good use for making complicated geometries with finer details.

Functional Parts: These are applicable when average strength is required.

Mold Production: Suitable for mold and lightweight parts.

Benefits:

Build speed is faster than Powder Bed Fusion.

No support structures are required, thus enabling more complex geometries.

Cost-effective for high-volume production of parts.

Drawbacks:

Lower density and mechanical strength compared to fusion-based methods.

Extensive post-processing is required for functionality.

Not suitable for high-performance applications.

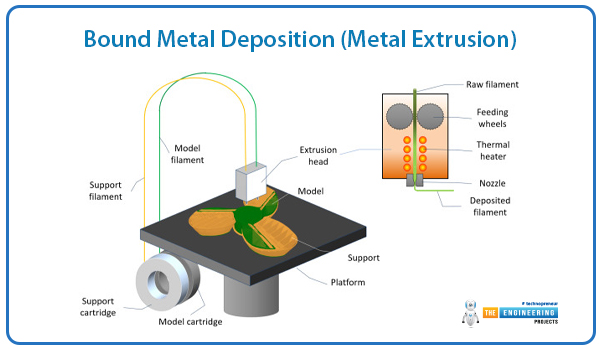

Bound Metal Deposition (Metal Extrusion):

Bound Metal Deposition, or metal extrusion, is a more affordable and secure alternative to metal 3D printing methods based on metal powders. BMD uses an extruded filament made of a polymer matrix binding metal powder for the layer-by-layer creation of parts. The technology is most valuable for low-volume production and prototyping.

Process:

The metal filament that includes the polymer matrix that binds the metal powder is melted and pressed through a nozzle to produce a "green part".

The part goes through debonding, where the polymer binder is removed from the part, leaving behind a metal framework.

Finally, the part is sintered within a furnace, where the metal particles fuse to increase the density and acquire the needed mechanical properties of the final product.

Applications:

Functional Prototypes: Ideal for the manufacture of components that are meant to be utilized during an early design phase as well as when testing them.

Tooling and Jigs: Best suited for low-run productions with special tooling and fixtures of production.

Benefits:

Costlier than powder-based methods like SLM and DMLS

Handling is safer and easier due to its filament form, which enables it to be used in a desktop or office environment

Application to small-run or functional part manufacturing in areas like automotive and aerospace

Disadvantages:

Parts will have lower density and mechanical strength than other methods.

Shrinkage during sintering may cause problems in terms of dimensional accuracy, requiring changes in design.

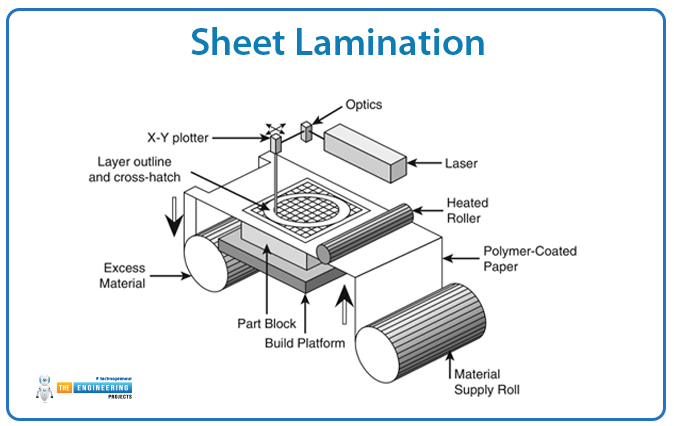

Sheet Lamination:

Sheet Lamination is a 3D metal printing process that involves the stacking and bonding of thin sheets of metal for building a part layer by layer. This is often used for parts made from the selective cutting and joining of metal sheets. The sheets can be bonded with methods such as laser cutting, ultrasonic welding, or adhesive bonding, hence allowing the development of complex shapes.

Process:

Thin sheets of metal are stacked on the build platform.

A laser or ultrasonic welding system cuts and bonds each layer to form the desired geometry.

The process is repeated, with each new sheet being cut and bonded to the previous layer until the part is fully formed.

Applications:

Prototyping and Low-Cost Manufacturing: Sheet lamination is very effective for rapid prototyping and low-volume manufacturing because it is both efficient and cost-effective.

Decorative and Structural Components: It is also suitable for the creation of components that require basic structural integrity or aesthetic appeal. For example, decorative parts for automotive and architecture can be manufactured quickly.

Advantages:

Minimal Waste: Sheet Lamination generates significantly less material waste compared to traditional machining or powder-based methods.

Fast Production Times: The process is quick, making it ideal for short turnaround times.

Material Versatility: It can handle multiple materials, including combinations of metals and non-metallic sheets.

Limitations:

Limited Geometries: The main disadvantage of the process is that is based on flat sheets, Sheet Lamination can accommodate only rather simple shapes of cross-section and does not allow the creation of, for example, tightly spiraled coils with a large number of turns.

Heat Sensitivity: Adhesively bonded parts are not standardized in terms of heat resistance their performance can deteriorate when exposed to high temperatures.

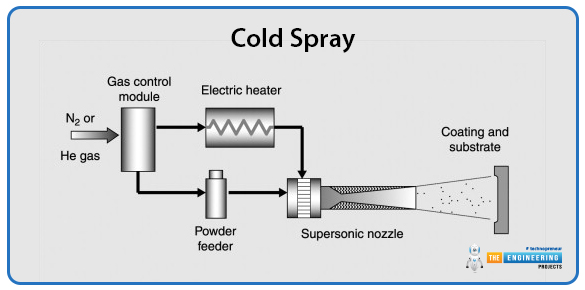

Cold Spray:

Cold Spray is one of the leading high-speed deposition techniques that are developed by accelerating through a nozzle of metallic powders carried by compressed gases and then depositing on a substrate. Unlike common metal deposition technologies, Cold Spray does not depend on melting down the metal but simply relies on kinetic energy to merge the particles onto the substrate.

Process:

The metal powders are then pelted into a high-velocity gas stream where the gas may be nitrogen or helium.

The powder attains velocity higher than the speed of sound, and due to the high energy acquired the particles stick to the substrate at impact.

The sprayed layers generated have minimal thermal distortion and, therefore, retain the properties of the material to be processed.

Applications:

Coating Applications: Cold Spray is mainly used for protection layers, which include anti-corrosion, wear, and anti-erosion protection. It is applied earliest for aerospace applications, automotive, and marine applications.

Repairing Damaged Components: The process is best suited for reconstructing worn or damaged parts because it allows it to add material to substrates without compromising its characteristics. It is especially helpful in repairing turbine blades and other engine components.

Advantages:

Dense Parts with No Melting: Since Cold Spray does not melt the metal during deposition, parts have excellent density and mechanical properties, with minimal porosity.

Preservation of Material Properties: It avoids thermal distortion that may otherwise degrade material properties in traditional melting-based processes. This makes it highly suitable for the preservation of the cut high-performance components.

Energy-Efficient and Environment-Friendly Process: Unlike the traditional pyrolysis process, there is no use of high temperature and a chemical reactor. Therefore, the process is energy-efficient effective, and also friendly to the environment

Limitations:

Limited to Ductile Metals: The cold Spray Process is not suitable for metals that need higher temperatures to develop bonds among them. This is because freet can be operated effectively on fully ductile materials such as copper, some titanium alloys as well as aluminum.

Post-Machining Requirements: Nonetheless, the process results in the density of a large part that calls for post-machining to achieve the required dimensional accuracy and surface finish.

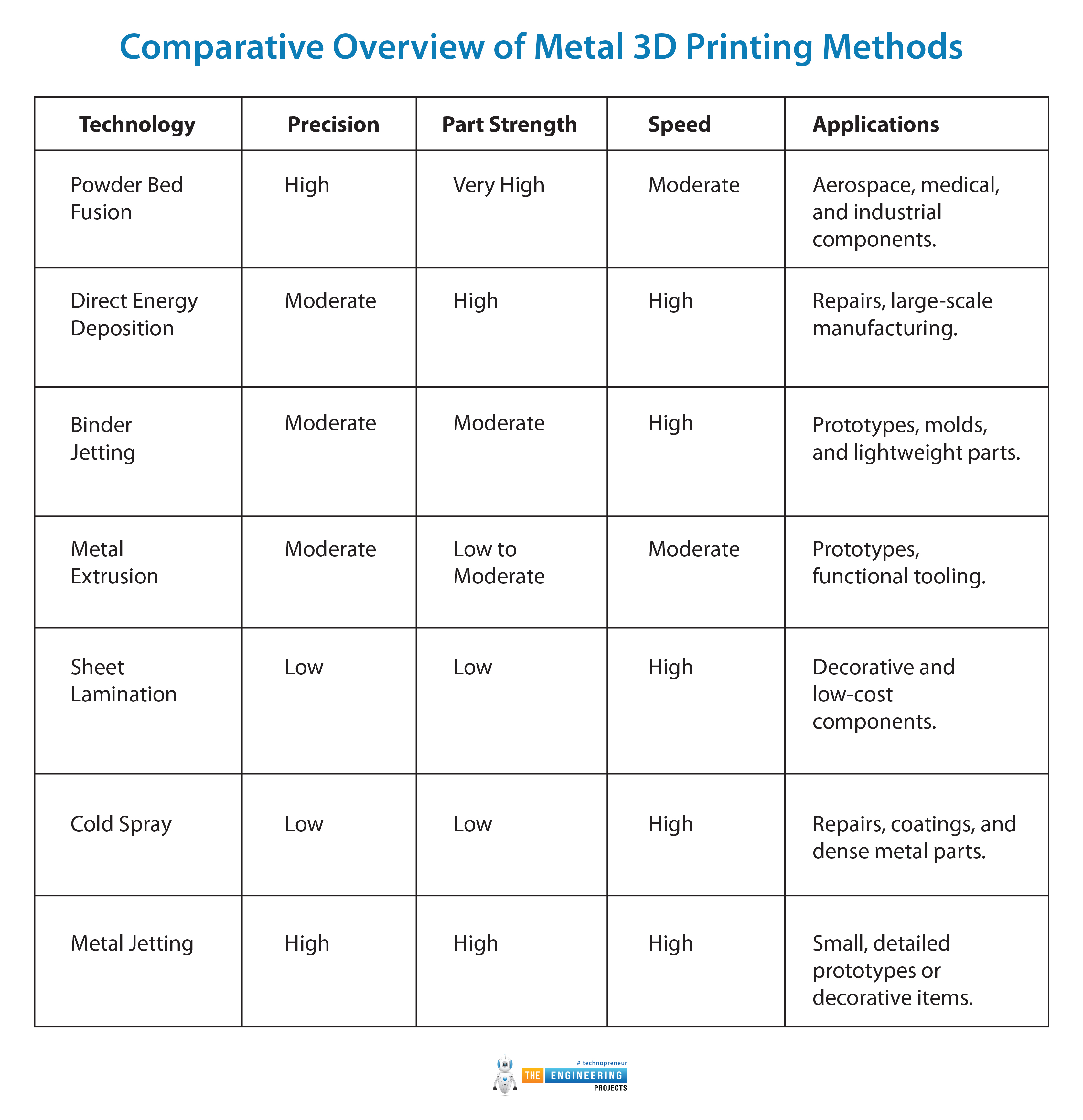

Comparative Overview of Metal 3D Printing Methods:

A brief comparison between the various contemporary methods of metal 3D printing is given below.

Technology |

Precision |

Part Strength |

Speed |

Applications |

Powder Bed Fusion |

High |

Very High |

Moderate |

Aerospace, medical, and industrial components. |

Direct Energy Deposition |

Moderate |

High |

High |

Repairs, large-scale manufacturing. |

Binder Jetting |

Moderate |

Moderate |

High |

Prototypes, molds, and lightweight parts. |

Metal Extrusion |

Moderate |

Low to Moderate |

Moderate |

Prototypes, functional tooling. |

Sheet Lamination |

Low |

Low |

High |

Decorative and low-cost components. |

Cold Spray |

Low |

Low |

High |

Repairs, coatings, and dense metal parts. |

Metal Jetting |

High |

High |

High |

Small, detailed prototypes or decorative items. |

Conclusion:

Metal 3D printing covers a broad spectrum of technologies, each providing a unique solution to specific industrial needs. Powder Bed Fusion (PBF), including Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), provides high precision and mechanical strength, ideal for aerospace, automotive, and medical applications. Direct Energy Deposition (DED) allows flexibility in repairing and enhancing parts and also enables large-scale production, while Binder Jetting is known for its rapid build speed and cost-effectiveness, making it very popular for prototyping and lightweight components. Metal Extrusion (Bound Metal Deposition) offers a safer and more economical way of creating functional prototypes and tooling. Sheet Lamination allows for fast, low-cost manufacturing but is only feasible for simpler designs.

Furthermore, Cold Spray is one of the critical technologies that create dense, hard parts through high-speed deposition. This technology has significant applications in coating and repair in the aerospace and automotive industries. Each of these methods has advantages that depend on the requirements of material properties, part complexity, and production speed. As new materials and techniques continue to evolve, metal 3D printing will be even more versatile, accessible, and integrated into various industries, revolutionizing manufacturing and design processes across sectors.

3D Printing

3D Printing xeohacker

xeohacker 0 Comments

0 Comments