In the fast-paced world of engineering, small mistakes can snowball into massive complications — especially when it comes to component identification, labeling, and documentation. Whether you’re managing an electrical system, a mechanical setup, or an IoT prototype, clear and accurate identification is the unsung hero that keeps everything running smoothly.

Yet, many projects suffer from avoidable identification errors that lead to maintenance delays, compliance issues, and even costly rework. The good news? Each of these mistakes can be prevented with a few simple best practices.

Let’s look at six of the most common identification mistakes engineers make — and how to fix them efficiently.

1. Using Inconsistent or Unreadable Labels

One of the most frequent mistakes is inconsistent labeling. When different team members use varying symbols, abbreviations, or numbering systems, confusion spreads quickly. It becomes difficult to trace connections, troubleshoot systems, or align documentation with the actual setup.

Example Scenario:

In an automation project, one team labels sensors as S1, S2, S3, while another labels them SEN_A, SEN_B, SEN_C. Later, when faults occur, identifying the correct sensor becomes a headache.

How to Fix It

Establish a standard naming convention at the start of the project.

Use clear, printed labels instead of handwritten ones.

For permanent industrial setups, consider using custom equipment nameplates that resist wear, moisture, and heat.

Document every label and its purpose in the project manual or shared file system.

Pro Tip: Use vector-based templates for nameplates so text and graphics remain crisp even at small sizes.

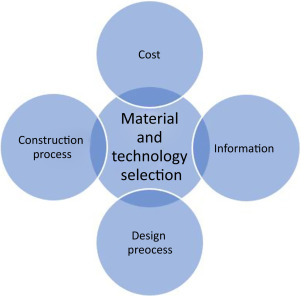

2. Ignoring Environmental Factors in Material Selection

Many engineers overlook the operating environment when choosing identification materials. For instance, a standard plastic tag might degrade quickly in a high-temperature or chemical-rich environment.

Environment Type |

Common Label Problem |

Recommended Material |

High Heat |

Melting or fading labels |

Anodized aluminum plates |

Outdoor/UV Exposure |

Color fading |

UV-resistant polycarbonate |

Chemical Exposure |

Smudging or corrosion |

Stainless steel nameplates |

High Moisture |

Peeling or mold growth |

Polyester with strong adhesive |

How to Fix It

Assess environmental conditions before selecting labeling materials.

For durability, use metal or laser-etched nameplates that are resistant to extreme conditions.

Regularly inspect labels and replace damaged ones during scheduled maintenance.

3. Poor Cable and Wire Identification

Cables and wiring are the lifelines of any electronic or automation project. When they’re not properly labeled, troubleshooting becomes a guessing game.

Common issues:

Overlapping cable tags

Faded ink on sleeves

Missing identification for power vs. signal wires

How to Fix It

Use color-coded sleeves or heat-shrink labels for clarity.

Mark both ends of each wire to avoid confusion.

Keep a digital wiring log or schematic updated with all cable IDs.

During simulation or circuit planning in tools like Proteus , apply virtual labels to mirror physical setups — this ensures consistency between design and implementation.

4. Skipping Version Control and Label Updates

Another subtle but damaging mistake is failing to update labels when components are replaced or upgraded. Engineers might update documentation but forget to modify the actual hardware tags — or vice versa.

How to Fix It

Implement version control for both hardware and documentation.

Use revision codes (e.g., V1.0, V1.1) on printed tags and digital schematics.

For large projects, consider a QR code or RFID-based labeling system that links to live documentation.

Review identification tags during every maintenance cycle to ensure they match the latest configuration.

Bonus Tip: Digital tagging systems save time during audits by ensuring all updates are synchronized automatically.

5. Not Following Industry Standards

Different engineering sectors — such as electrical, mechanical, and process control — have established standards for component identification. Ignoring these not only leads to confusion but can also cause compliance issues.

How to Fix It

Familiarize your team with standards like:

IEC 81346 for industrial systems

ANSI/ISA 5.1 for instrumentation

ISO 14617 for graphical symbols

Incorporate these standards into your project’s labeling policy.

Use consistent prefixes, numbering, and symbology across all documentation and hardware.

A little effort in standardization goes a long way toward ensuring that future engineers and maintenance teams can easily understand your system layout.

6. Overlooking Documentation and Label Mapping

Even when labels are applied correctly, failing to document them properly is a major oversight. Without a central reference, future maintenance teams have to re-identify each part manually — wasting time and increasing the risk of errors.

How to Fix It

Maintain a Label Reference Sheet or Component Mapping Table that lists all tags, their locations, and descriptions.

Keep both printed and digital copies accessible to the entire team.

Update the mapping document whenever a new component or sensor is added.

Here’s a simple example of how a label mapping table can be structured:

Component ID |

Description |

Location |

Status |

S1 |

IR Proximity Sensor |

Control Panel A |

Active |

M1 |

DC Motor (Right) |

Conveyor Unit |

Active |

R3 |

10kΩ Resistor |

Breadboard Row D |

Replaced |

D2 |

Indicator LED |

Board Front Edge |

Functional |

This organized approach ensures that even years later, anyone revisiting the project can quickly identify and understand each part.

Bringing It All Together

Accurate identification is the backbone of successful engineering projects. It saves time, reduces risk, and ensures the system remains maintainable and compliant throughout its lifecycle. By standardizing labels, choosing the right materials, and keeping documentation in sync, engineers can avoid the most common identification pitfalls.

If you’re working on industrial or long-term engineering systems, investing in durable custom equipment nameplates is one of the simplest ways to ensure lasting clarity and professional presentation.

Additionally, before you build, always simulate — using platforms like Proteus helps verify labeling logic and wiring organization, reducing physical rework later. You can explore more tools and libraries in this Proteus resources guide for smoother project execution.

Final Thoughts

Mistakes in identification are easy to make — but just as easy to fix with the right mindset. Think of labeling and documentation as part of your design, not an afterthought. A well-identified project isn’t just organized — it’s safer, easier to maintain, and more professional.

Taking time to label right today saves countless hours of confusion tomorrow — and that’s what great engineering is all about.

Tutorials

Tutorials xeohacker

xeohacker 0 Comments

0 Comments