Hi readers! Hopefully, you are having a great day and exploring to learn something new. Heat is the silent killer in power electronics, and thermal vias are the unsung heroes that keep your circuit cool under pressure.

As electronic devices are miniaturized and powered with higher power, the amount of heat generated by high-speed and high-power devices has increased significantly. Proper thermal management is now one of the greatest challenges of modern-day PCB (Printed Circuit Board) design. Whether it is power supplies and LED light systems, or processors and RF modules, all electronic circuits are heat-generating. Unless treated carefully, such heat can cause degradation of components, reduced performance, signal instability, and even irreparable system damage.

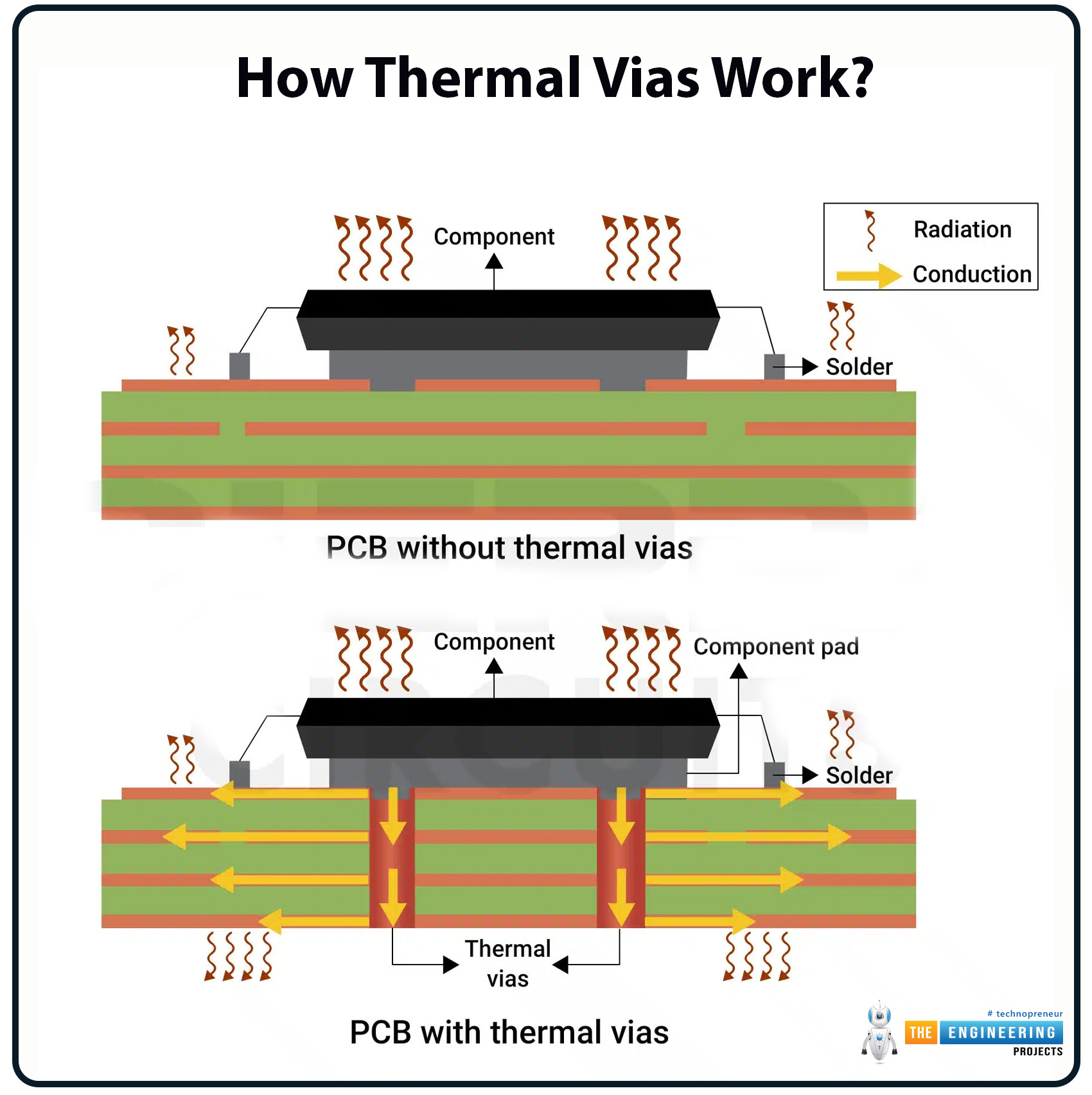

To prevent such issues, designers must incorporate efficient cooling systems. Thermal vias are the most economical and efficient method. They consist of small, vertically drilled holes in copper-plated PCBs designed for heat conduction but not for electrical connection. Thermal vias create an efficient thermal path by transferring heat from the board surface, where components that generate heat reside, to inner copper levels or external heat sinks.

It not only lowers the temperature of critical components but also improves the overall thermal equilibrium of the PCB. Thermal vias significantly improve the reliability, performance, and lifespan of high-power electronic components and thus form an indispensable part of thermal design guidelines in present times.

This this article, you will learn about thermal vias, their characteristics, why it is important in PCBs, how they work, their types, and applications. Let’s unlock.

Where to order PCB Online?

If you're looking to order high-quality PCBs online, then NextPCB is where you should look, the first choice for engineers, makers, and startups alike. With rapid production, affordable prices, and great service, NextPCB has got it all from basic 2-layer boards through to complex multi-layer and HDI designs. Their streamlined ordering process makes it easy for you to simply upload your Gerber files, choose your specs, and place your order in no time at all, ideal for a novice or expert.

What sets NextPCB Fabrication House apart from others is its end-to-end service. Besides PCB manufacturing, they also provide stencil manufacturing, procurement of components, and full turnkey assembly. From prototype to full production orders, NextPCB does it all in-house, saving you effort and time. Ordering is simple, easy, and takes you from design to production very quickly and safely, with a partner you can trust.

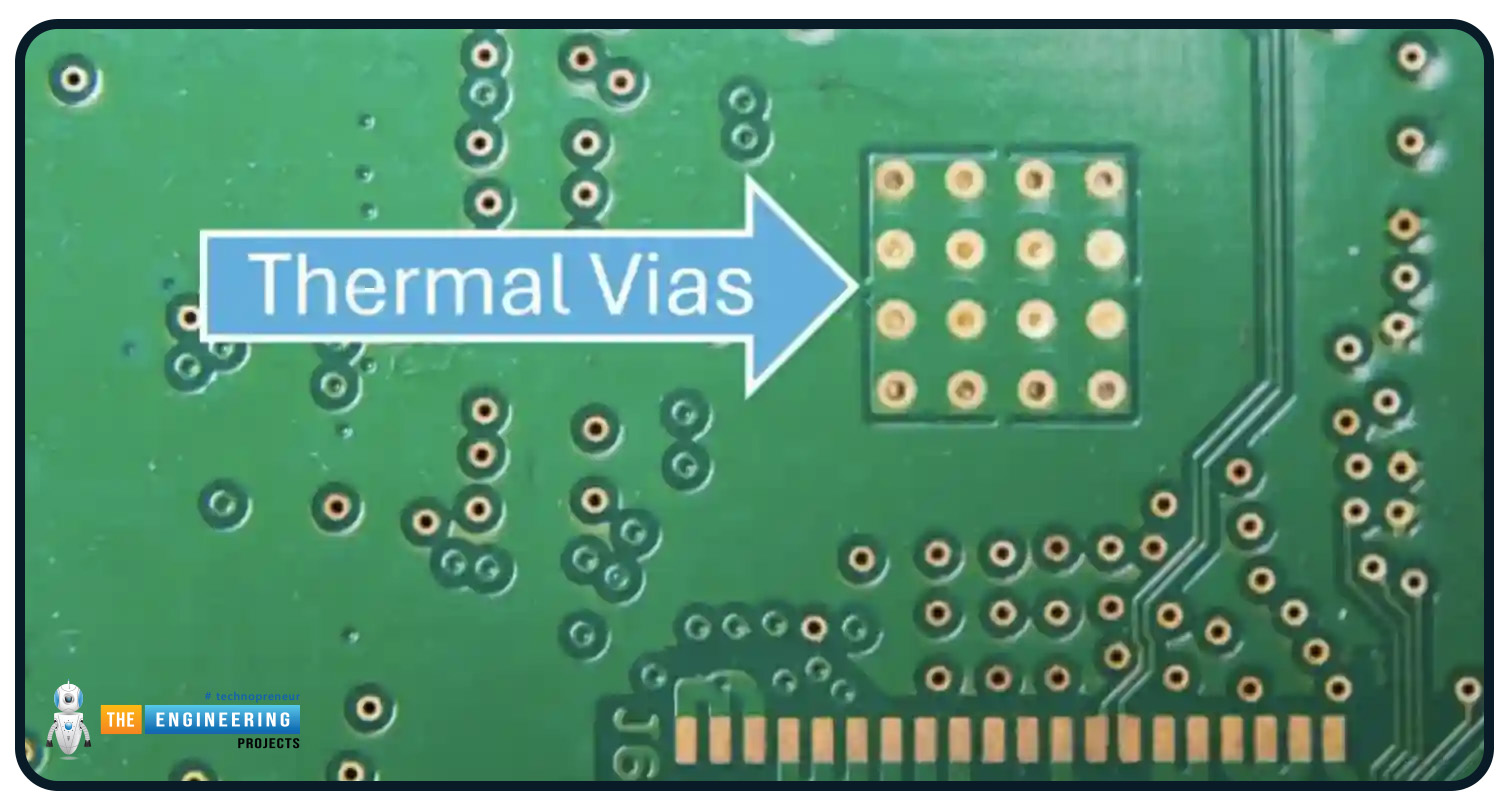

What Are Thermal Vias?

Thermal management is a vital aspect in high-power applications on today's PCBs to achieve a reliable and optimally performing device. Examples are LEDs, power transistors, and voltage regulators, which generate huge amounts of heat from load conditions. Thermal vias, small plated holes in the PCB, provide a direct thermal conduction path from components to internal copper layers or sinks. Contrarily, thermal vias are designed to conduct distributed heat away to prevent an over-temperature in the components rather than as a regular signal via. They facilitate the heat dissipation and thus lead to increased longevity and steadiness of electronic devices, which is now necessary concerning today's high-power and density PCB applications.

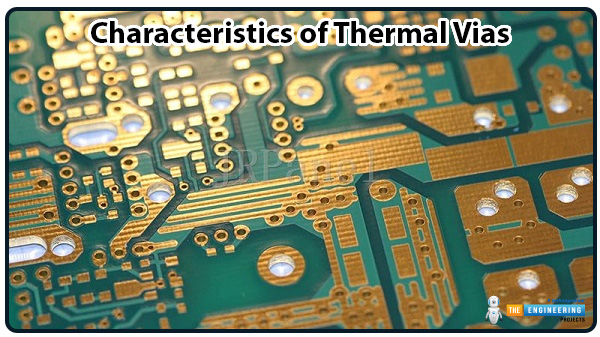

Characteristics of Thermal Vias:

Thermal vias are crucial components in printed circuit boards (PCBs) employed for heat management generated by power-dissipating components. Unlike normal signal vias, they possess as their principal purpose thermal, not electrical, conductivity. It is important to know how they work and what they look like so that high-power electronic systems can be designed with reliability.

Plated Through-Hole Construction:

Thermal vias, as the name implies, are plated through holes (PTH) drilled right through the PCB. The plating is on the side walls of the holes, which is the path of conduction of heat from the board surface to the inside or back copper layers. The thickness and quality of the copper plating are directly responsible for how efficiently the via conducts heat as well. For example, a thicker layer will conduct the heat more efficiently.

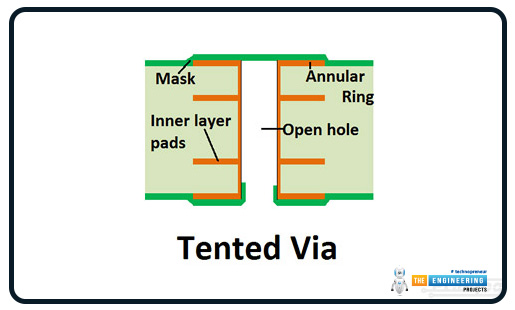

Some thermal vias may be filled with conductive material to provide increased thermal flow or tented depending on whether solder paste is passing over them.

No Function in Signal Routing:

Unlike electrical vias, thermal vias do not route signals from one layer to another. They are typically situated beneath components that dissipate heat, such as power transistors, voltage regulators, or LEDs, where thermal vias will be used just to conduct the heat away from the device. Since there is no real concern about noise or maintaining signal integrity, designers are more flexible in using solid arrays of vias, which will give better thermal performance. That is the purpose of thermal vias. Thermal vias allow heat to flow from the hot surface to internal copper planes or heat sinks, which lowers the temperature at the source.

Connection to Copper Planes:

The thermal via is a bridge between a hot surface pad and the internal or bottom copper layers, which are heat spreaders. The copper layers spread and dissipate heat, thereby avoiding high temperature buildup in the component.

On a 2-layer PCB, thermal vias may be interfaced to a bottom-side copper pour. In multi-layer boards, they may be interfaced with several internal layers so heat can spread more effectively through the stack of the PCB. Thermal pads or heat sinks may also be affixed over the copper area interfaced to the vias on certain designs to provide for increased dissipation.

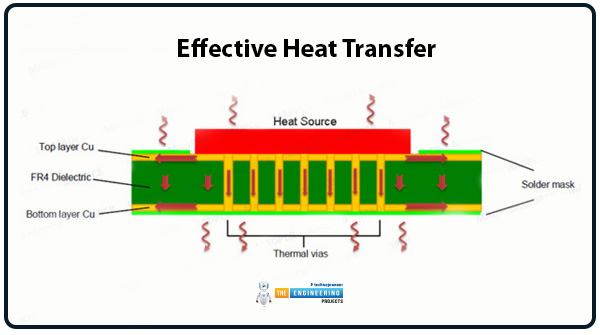

Effective Heat Transfer:

With the use of copper's high thermal conductivity (~400 W/m·K), thermal vias minimize thermal resistance between the component and heat-spreading layers. This keeps the operating temperatures stable, prevents thermal failure, and improves circuit reliability overall.

Thermal vias, in short, provide a simple, passive, and effective way to manage heat in high-power PCB designs without adding complexity to electrical routing, yet are essential to thermal performance.

Scalability:

Thermal vias are flexible and can be applied to anything from basic two-layer boards to intricate multilayer HDI PCBs. The size, number, and pattern of vias can be scaled based on the cooling and power needs of the device.

Manufacturing Flexibility:

These vias can be produced using regular PCB manufacturing processes. They could be left open, tented with solder mask, or filled with epoxy or metal for enhanced performance. This makes it possible for designers to customize the vias to functional and manufacturing requirements.

Size and Density:

Thermal vias are usually between 0.3 mm and 0.5 mm in diameter. They improve their thermal performance when they are densely populated, particularly under surface-mount component thermal pads. Increased via density enhances the effective thermal conductivity of the path.

Cost-Effective Passive Solution:

Thermal vias present a passive cooling solution with no extra components needed, so they are economical. They're perfect for small designs where active cooling (such as fans or heavy heat sinks) is impossible. Simple as they are, they are crucial in the long-term performance and reliability of high-power electronics.

Why Heat Dissipation is Important:

Power and performance, unfortunately, tend to come in concert with heat in today's electronics. With PCBs populated by quicker processors, energy-intensive LEDs, and densely packed voltage regulators, the outcome is straightforward: more heat in a smaller space. And when that heat isn't dissipated correctly, it begins to create serious issues.

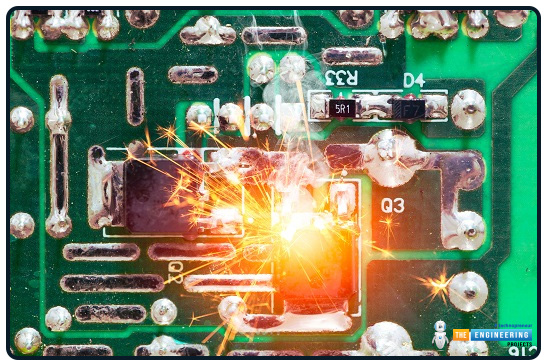

Heat, Electronics Trouble:

Excessive heat is a quiet killer. It seeps in and begins to cause problems that will not necessarily be apparent at first, but eventually, they result in deterioration and breakdown. When parts run hotter than their design temperatures, the internal materials start to degrade more quickly. Integrated circuits, for instance, can incur permanent damage if their junction temperature rises beyond safe tolerances. Heat also raises electrical resistance in copper traces, lowering the efficiency of a circuit and distorting signal integrity in high-speed designs.

Solder Joints Don't Like Heat Either:

It's not only the components that are at stake. Solder joints, the same joints that keep components secure, are susceptible to heat, too. When a board is repeatedly heated and cooled (known as thermal cycling), the solder contracts and expands. This causes fatigue and cracking over time, particularly beneath components that produce a great deal of heat. Cracking joints equates to an unreliable connection, which can lead to everything from flickering LEDs to a dead board entirely.

Heat Damages the Board Itself:

PCBs consist of materials such as FR4 that have only so much ability to endure heat. Prolonged heat exposure weakens the core of the board, destroys insulation between layers, and even causes delamination (peeling away of the layers). High power usage is a serious reliability issue in these cases. If the base material deteriorates, the entire board can fail despite all the components remaining intact.

Not optional, it's essential:

For power electronics, automotive control, and industrial system engineers, good thermal management is not a nice-to-have; it's a requirement. When the PCB is being designed, the heat needs to be thought through so it can be allowed to escape. Without thermal vias and other methods to spread the heat, you're left with the risk of premature failure of your component, increased maintenance, or a recall of the product altogether.

A Good Design Starts With Cooling:

No matter what the event, the ultimate goal of a PCB design is reliability; the secret to reliability is in thermal management. This could be adding copper, component placement, or effectively utilizing thermal vias; the more ways that you can manage heat, the more you can increase your product's life cycle and performance.

Don't forget, you can't visualize heat, but if you don't pay attention to it, your design won't last long.

How Thermal Vias Work?

Thermal vias are an important aspect of high-power PCB design, and they form a low-resistance path for heat to travel away from the hot components. Below is how they work in detail:

Heat Transfer Path:

Thermal vias are normally located underneath or near heat-dissipating components such as MOSFETs, power ICs, and LEDs. They conduct heat from the surface layer where these components are soldered or mounted down through the PCB to inner copper planes or a bottom-side heatsink. Vertical heat flow aids in keeping safe operating temperatures on the surface.

Copper-Plated Conduits:

Each via is copper-plated, which is a good conductor of heat. When thermal energy builds up in the component pad, it migrates through the copper walls of the via and is distributed into larger copper areas beneath. These are heat sinks, which spread the energy across the board.

Factors Influencing Effectiveness:

Thermal via effectiveness relies on:

Number and density of vias: The more vias, the quicker the heat transfer.

Thickness of copper plating: Thicker walls are better conductors.

Daisy chaining of copper pours or thermal pads: Proper contact is critical for effective heat spreading.

Mini Heat Channels:

Thermal vias act as miniature heat channels, quietly doing their job of cooling high-power devices, making them efficient and long-lived.

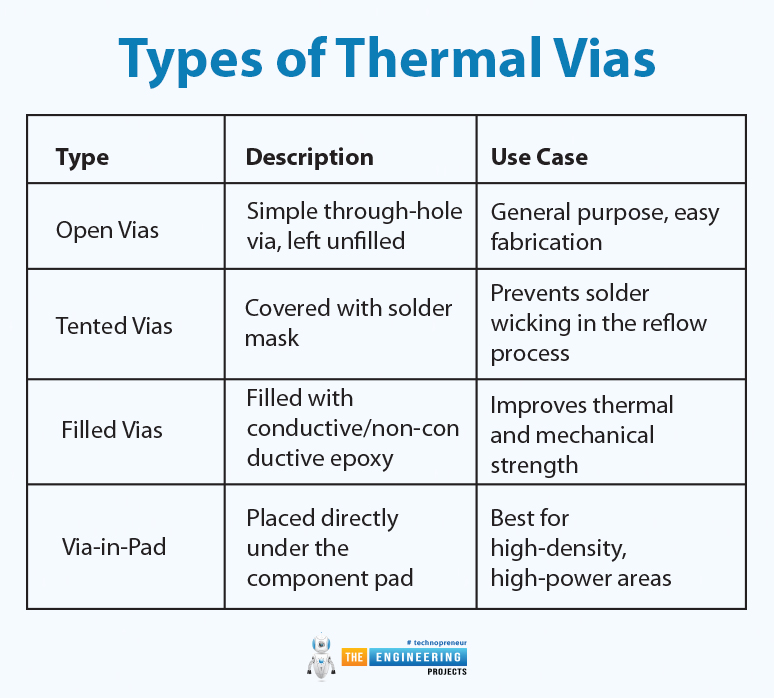

Types of Thermal Vias:

Type |

Description |

Use Case |

Open Vias |

Simple through-hole via, left unfilled |

General purpose, easy fabrication |

Tented Vias |

Covered with solder mask |

Prevents solder wicking in the reflow process |

Filled Vias |

Filled with conductive/non-conductive epoxy |

Improves thermal and mechanical strength |

Via-in-Pad |

Placed directly under the component pad |

Best for high-density, high-power areas |

Real-World Applications of Thermal Vias:

1. Power Electronics:

Thermal vias play a crucial role in power-dissipating circuits such as DC-DC converters, motor drivers, and power amplifiers. All these applications dissipate considerable heat, particularly near power MOSFETs and regulators. Vias facilitate this heat transfer to internal copper planes or bottom-side heat sinks to ensure stability.

2. LED Lighting:

High-brightness LEDs can quickly overheat unless well-cooled. Excess heat is directed into metal-core PCBs (MCPCBs) or external heat sinks through thermal vias located under the LED pads, slowing lumen degradation and extending LED lifespan.

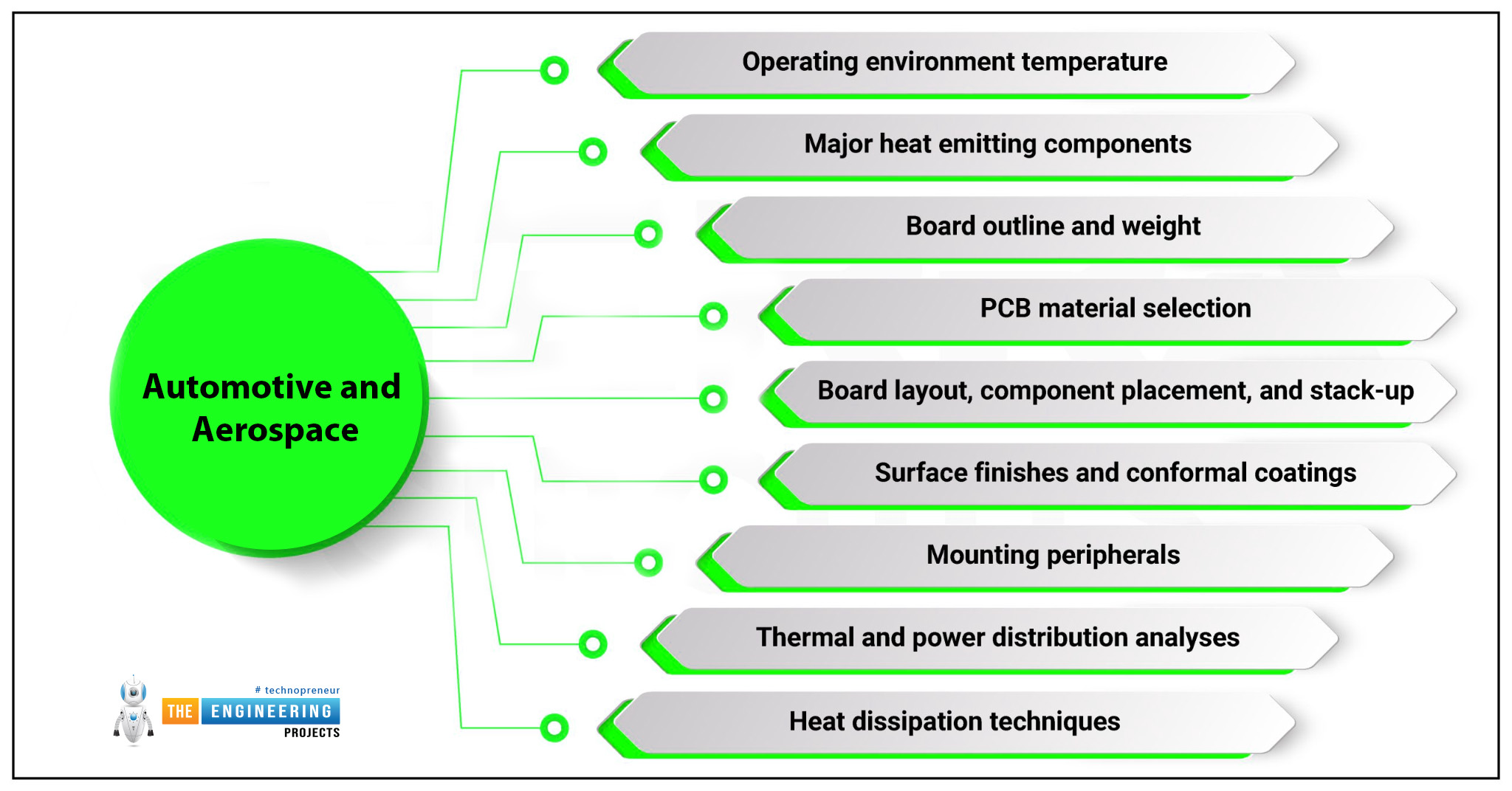

3. Automotive and Aerospace:

Where there are severe environments and higher ambient temperatures, such as in automotive ECUs or aerospace control units, operational safety and prevention of thermal failure of essential systems are ensured by thermal vias.

4. Consumer Electronics:

Small devices like laptops, mobile phones, and game consoles employ thermal vias for silent, passive cooling. Thinner designs are enabled without large fans or external heat sinks.

Conclusion:

The reliance on the proficiency of thermal management is increasing as electronic systems advance further. It is safe to estimate that as power densities increase and device sizes decrease, conventional cooling schemes become less and less effective. As such, thermal vias are a smaller, reliable, and effective way of dissipating heat from key components to retain a stable, well-functioning system over a long period.

From power electronics and LED lighting to space and consumer devices, thermal vias are integral to prolonging product life and ensuring reliability in extreme or thermally abusive environments. The fact that they can quietly and passively dissipate heat without contributing to size makes them a precious commodity in today's PCB design.

In the future, the smart placement and optimization of thermal vias will be a determining aspect in obtaining high-performance electronics. Engineers who can think intelligently about how to strategically integrate these features will have a clear edge in creating strong, thermally efficient, and long-lasting products for the future.

Printed Circuit Boards

Printed Circuit Boards xeohacker

xeohacker 0 Comments

0 Comments