Natural Gas Flow Meter Types and Applications

In modern industries, natural gas is a crucial energy source used in power generation, chemical processing, heating systems, and fuel supply networks. To make sure everything runs efficiently and safely, accurate measurement of gas flow is essential—for example, to ensure a gas-fired power plant operates at optimal fuel efficiency or to maintain proper conditions in a chemical reaction.

However, there’s no single “perfect” gas flow meter, as each type comes with its own advantages and limitations. The following overview introduces the most common types of flow meters used for natural gas , how they work, and the applications where they are most effective.

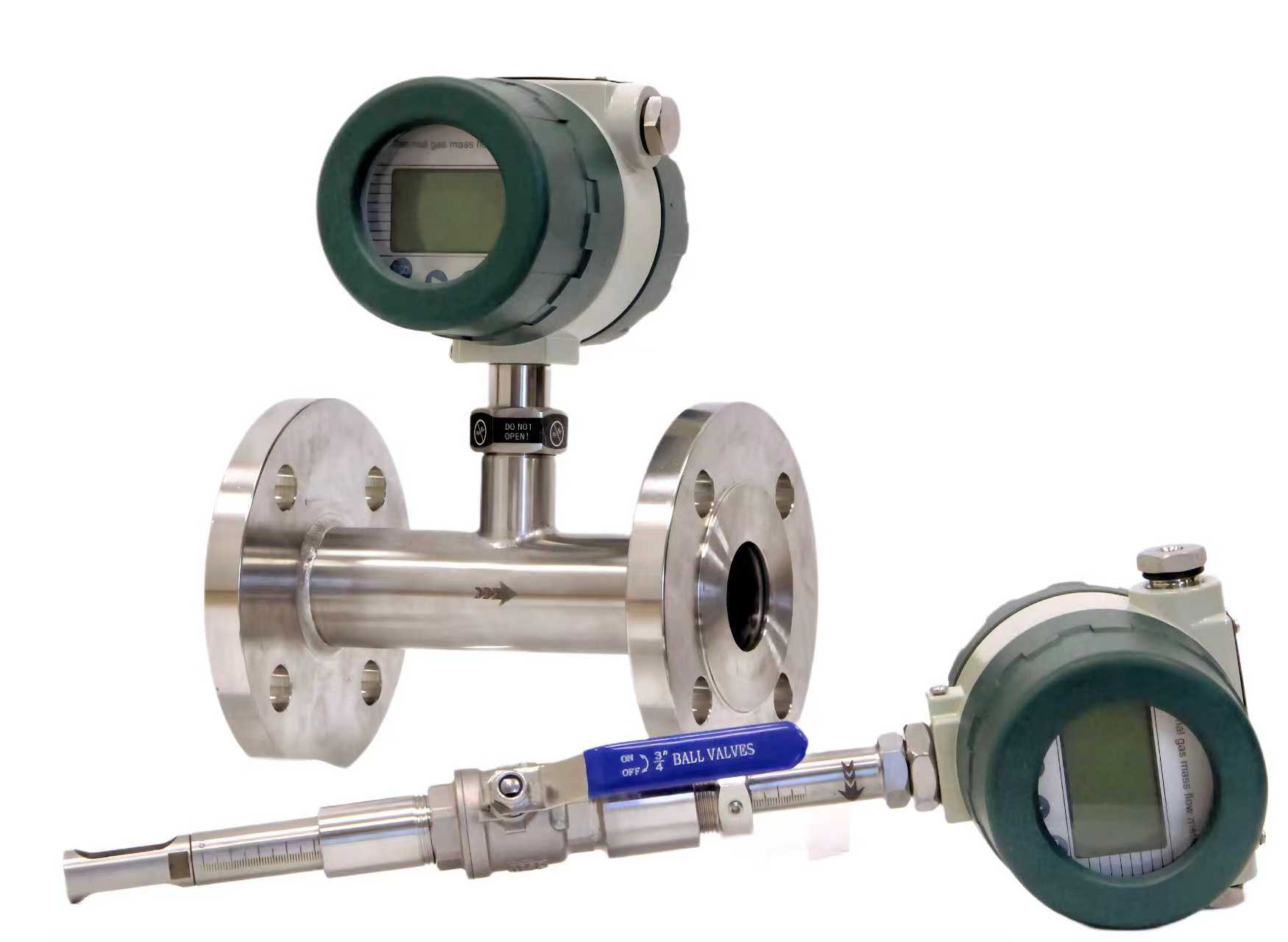

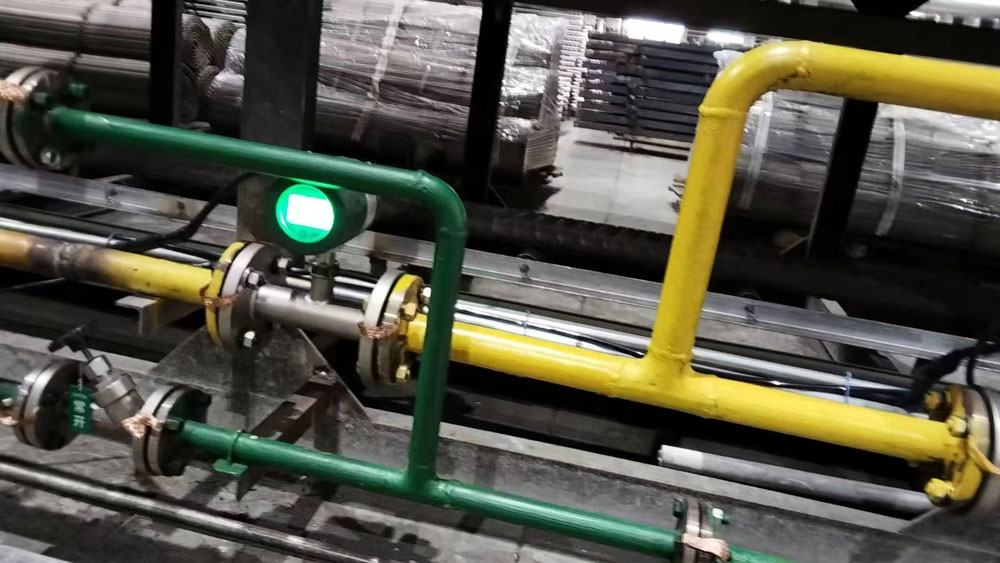

1. Thermal Mass Flow Meter– Simple and Precise Measurement for Gases

The thermal mass flow meter measures gas flow by detecting heat transfer. Inside the meter, a heated sensor and a reference sensor monitor temperature changes as gas passes through. The resulting temperature difference, proportional to the gas mass, is converted into a flow signal.

Advantages

- Measures mass flow directly.

- No need for additional temperature or pressure compensation.

- High sensitivity for low flow detect and wide measurement range.

- No moving parts, resulting in low maintenance

Applications

Thermal gas flow meters are used for natural gas, biogas, compressed air, and flare gas. They are typically installed in boilers, burners, and air systems where precise flow measurement is required. These meters can detect low flow rates, making them suitable for leak detection applications.

2. Coriolis Mass Flow Meter– Direct Mass Flow Measurement

The Coriolis mass flow meter measures gas mass by detecting the Coriolis force in vibrating tubes. As gas passes through U-shaped tubes, it slightly twists the vibration pattern, and this phase shift is proportional to the mass flow. In addition to mass, the mass meter can provide real-time measurements of cryogenic LNG (Liquid natural gas) flow measurement, which can be very useful when precise monitoring is needed.

Advantages

- Direct mass flow measurement.

- Exceptional accuracy (typically ±0.1–0.5% of reading)

- Can be used for LNG low-temperature natural gas measurement.

- Works well for high-pressure gas measurement

Applications

Coriolis flow meters are commonly used in custody transfer, compressed natural gas (CNG) systems, and industrial process control. It provides reliable measurement in applications where precision is essential. The cost is generally higher than other types, but the additional investment reflects the level of reliability and accuracy offered.

3. Differential Pressure (DP) Flow Meter– Classic Method with Proven Reliability

Differential pressure flow meters calculate gas flow by measuring the pressure drop across a restriction, such as an orifice, nozzle, or Venturi tube. The pressure difference allows determination of volumetric flow, and with compensation for temperature and pressure, mass flow can also be derived.

Advantages

- Simple and robust construction

- Well-proven and standardized technology

- Suitable for high-pressure gas pipelines

- Cost-effective for many industrial applications

Applications

People often use DP flow meters to measure energy, in natural gas transmission pipelines, and in boiler fuel systems. They are often selected when reliability and simplicity are more important than high-end accuracy.

4. Turbine Flow Meter– High Accuracy under Stable Flow Conditions

Turbine flow meters measure gas flow by tracking the rotation of a rotor placed in the flow path. Gas spins the rotor, and a sensor converts its rotational speed into flow rate. Combining this with temperature and pressure data, the meter calculates mass flow.

Advantages

- Good accuracy and repeatability

- Fast response time

- Ideal for clean and dry gas

- Cost-effective for moderate flow ranges

Applications

Turbine flow meters are used to keep track of how much gas is being used in natural gas distribution systems, CNG filling stations and industrial gas consumption. They perform best in clean gas conditions and should avoid dirty or moisture-laden gases, which can damage the rotor.

5. Ultrasonic Flow Meter– Non-Intrusive and Maintenance-Free

Ultrasonic meters measure flow using sound waves, without touching the gas. Two transducers send and receive pulses across the flow. The meter calculates flow from the difference in transit time, using pipe size and gas properties to get volumetric flow.

Advantages

- No moving parts and no pressure loss

- High accuracy and excellent long-term stability

- Easy installation and minimal maintenance

- Works well for large-diameter pipelines

Applications

Ultrasonic flow meters operate in natural gas transmission lines, city gas distribution networks, and pipeline leak detection. They measure flow accurately without interfering with the gas, and their wide measurement range suits high-capacity systems.

How to Select the Right Gas Flow Meter

There are a number of things to think about when choosing the right gas flow meter, such as the type of gas, the pressure, operation temperature, accuracy demand, the flow range, the installation conditions, and the budget.

Comparison Table

Flow Meter Type |

Key Advantage |

Ideal Application |

|---|---|---|

Thermal Mass |

Direct mass flow, no pressure loss |

Low flow, leak detection, compressed air |

Coriolis |

Highest accuracy, mass and density measurement |

Custody transfer, CNG, precision control |

Differential Pressure |

Low cost, simple design |

High-pressure pipelines, boiler fuel |

Turbine |

Accurate for clean gases |

Gas distribution, refueling systems |

Ultrasonic |

Non-intrusive, large flow range |

Transmission lines, leak monitoring |

Factors to Consider

- Composition and cleanliness of the gas

- Pipe diameter and available straight run length

- Required measurement accuracy

- Installation environment (indoor, outdoor, or hazardous)

- Long-term maintenance and calibration costs

FAQ – Gas Flow Meter for Natural Gas

Q1: What is the difference between mass flow and volumetric flow?

Mass flow measures the amount of gas that is actually moving through the pipeline, no matter what the temperature or pressure is. Volumetric flow, on the other hand, measures the volume of gas, which changes with temperature and pressure.

Q2: Can one flow meter be used for all types of gas?

Not always. Some meters, like Coriolis and thermal mass meters, can handle multiple gases with proper calibration. DP and turbine meters may require adjustments based on gas properties.

Q3: Which flow meter is best for custody transfer or billing?

Coriolis and gas turbine flow meters are better because they are more accurate and stable.

Q4: How often should gas flow meters be calibrated?

It depends on the type and application. Typically, every 12–24 months ensures accurate readings.

Q5: Which gas flow meters require the least maintenance?

Thermal mass and ultrasonic flow meters have no moving parts, making them the lowest-maintenance options.

Q6: Can gas flow meters measure both mass and volume?

Yes. Coriolis meters measure mass directly, and with additional calculations, volumetric flow can be derived. DP and turbine meters primarily measure volume and require compensation for mass flow.

Q7: Are ultrasonic flow meters affected by pipe conditions?

Yes. To get accurate measurements, the pipe should be installed correctly and be the right length. Impurities or turbulence can also change the readings.

Natural gas flow measurement is vital for many applications

Accurate natural gas flow measurement is vital for energy management, safety, and process optimization. Each gas flow meter technology — thermal, Coriolis, differential pressure, turbine, and ultrasonic — has its own strengths and best-fit scenarios.

For general monitoring and process control, thermal mass and DP flow meters offer reliable performance at a lower cost. For high-accuracy or custody transfer applications, Coriolis and ultrasonic technologies provide superior precision. Turbine flow meters remain a practical choice for clean, stable gas conditions.

By understanding the working principles and characteristics of each meter type, engineers and system designers can make informed decisions and ensure consistent, accurate natural gas measurement in any industrial setup.