Precision Metal Additive Technology

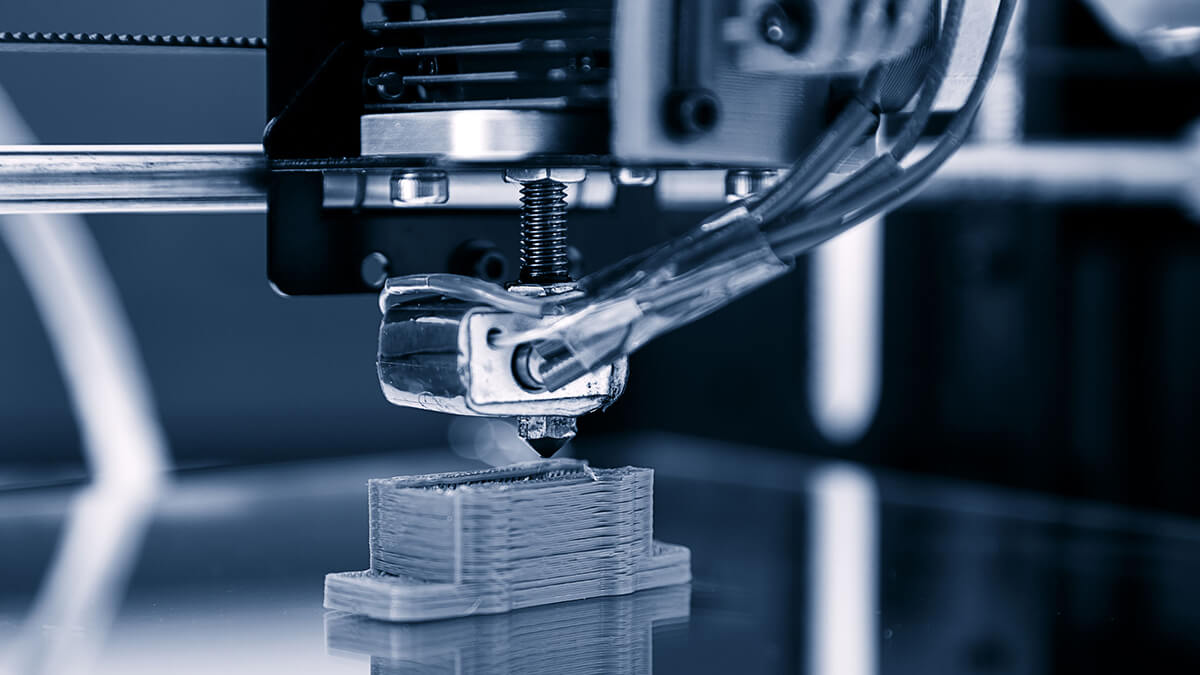

A few days ago, Mantle remerged onto the market with its new True-shape 3D printing technology aimed at reducing the manufacturing time in the tooling sector. The company has great success with its mould and additive technology so far. According to a global appliance manufacturer, the use of a Mantle mould resulted in 67 percent fewer costs and a 70 percent reduction in production time. It is hoped that the new Trushape hybrid metal printing technology will yield the same results for the tooling industry by reducing the time between developing and procuring tools using flowable metal paste such as steel.3D Printing And Additives In Metal Fabrication

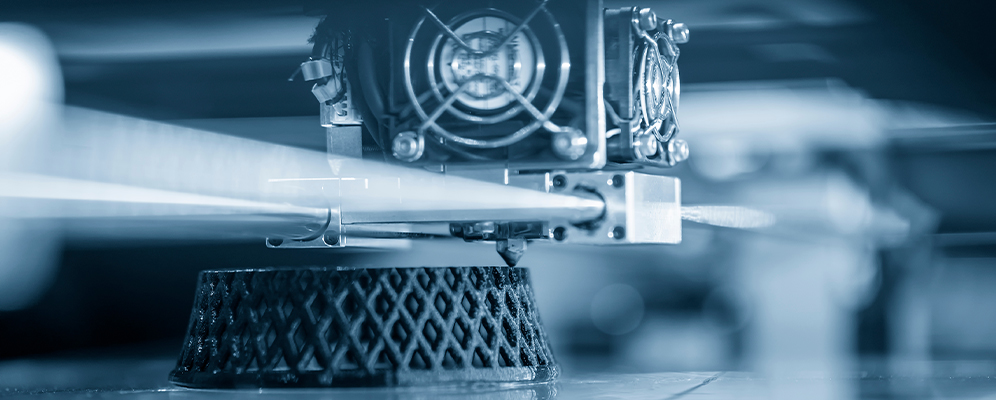

Additive manufacturing is also being used in sheet metal fabrication. Different grades of titanium metal sheet have been used in additive manufacturing by many industries including the aerospace industry for rotors and compressors, along with the medical industry for the manufacturing of orthopedic implants. A few years ago, automotive manufacturer General Motors also garnered a lot of interest when it unveiled a 3D printed seat bracket, made from stainless steel. This kick-started a conversation on how useful and feasible additive manufacturing would be in some industries such as automotive manufacturing. Some manufacturers have chosen to go ahead with exploring its use. This year, the Bugatti Bolide will hit the market and includes 3D printed titanium and carbon fiber throughout its body. Competitor, Chevrolet already uses 75 printed parts in its Corvette models but its use in the industry remains questionable when it comes to mass production.

Industrialization Of Additive Manufacturing

In the past years, the use of additive manufacturing has been mainly aimed at the development of prototypes or customized machinery parts. For instance, NASA’s Rapid Analysis and Manufacturing Propulsion Technology (RAMPT) initiative rely on the use of additive manufacturing and 3D printing to print customized rocket parts using metal powder and blown powder directed energy deposition. Time and cost roadblocks have hindered the increased industrialization of AD across many other industries. Now, with projections from Siemens and other companies estimating that additive manufacturing will become 50 percent cheaper and 400 percent faster by 2023, companies are exploring potential partnerships to achieve industrialization.

Tutorials

Tutorials ayeshayounas

ayeshayounas 0 Comments

0 Comments