Hi readers! I hope you are doing well and exploring something new. When power collides with simplicity, and toughness doesn't require sacrifice, welcome to the PETG universe, the 3D printing material changing the game. Today, we will discuss PETG Filament.

In the increasingly vast 3D printing universe, selecting the correct filament can be the difference between a perfect print and a mind-bending failure. Make your move, PETG (Polyethylene Terephthalate Glycol-modified), the new kid in 3D printing that mixes toughness, flexibility, and simplicity better than all others. Many praise PETG for being an excellent middle-ground between gentle-but-fragile PLA and tough-but-unstable ABS.

What pet owners like most about PETG is its special power to balance mechanical strength with superior printability. It has wonderful layer adhesion, minimal warping, tremendous impact resistance, and a luscious glossy surface—all without the expense of an enclosed printer. Whether you're making functional machine parts, production-grade prototypes, or transparent presentation models, you can depend on PETG prints.

Its chemical, water, and UV resistance make PETG not only tough but resilient in the real world. Through its wide range of bright colors and clarity, you've got a filament that's as reliable as it is versatile.

Here we'll learn why PETG is so popular among makers and how you can get the most out of it with your 3D printing endeavors. In this article, we will know about PETG Filament, its physical properties, material composition, characteristics, printing settings, applications, and common issues. Let’s dive in to unlock details.

What is PETG Filament?

PETG (Polyethylene Terephthalate Glycol-modified) is one of the most common 3D printing materials around today due to its utility and durability, encompassing ease of use as well. It fundamentally started as PET (a common plastic with usage in water bottles and wrapping), but PETG also has glycol integrated to reduce brittleness, improve impact strength, and improve optical characteristics. With this modification, the material has the best qualities of both PLA and ABS, being flexible as well as tough.

Since PETG can resist chemicals, is heat stable, and doesn’t warp, it is appropriate for functional prototypes, parts used in machines, and items meant for mass production. Its low shrinkage provides excellent layer bonding and accuracy of dimensions. PETG is also safe to use as a food contact material (in certain grades) and is commonly used in medical and consumer products. Its clarity and smooth surface finish make it even more desirable. In general, PETG is a versatile and dependable filament for many 3D printing applications.

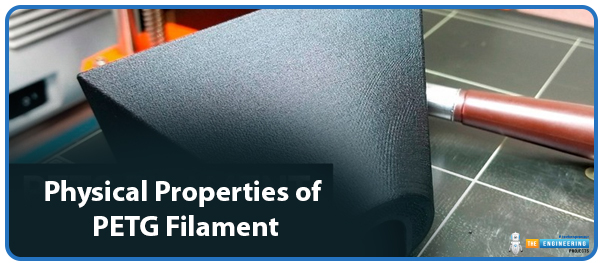

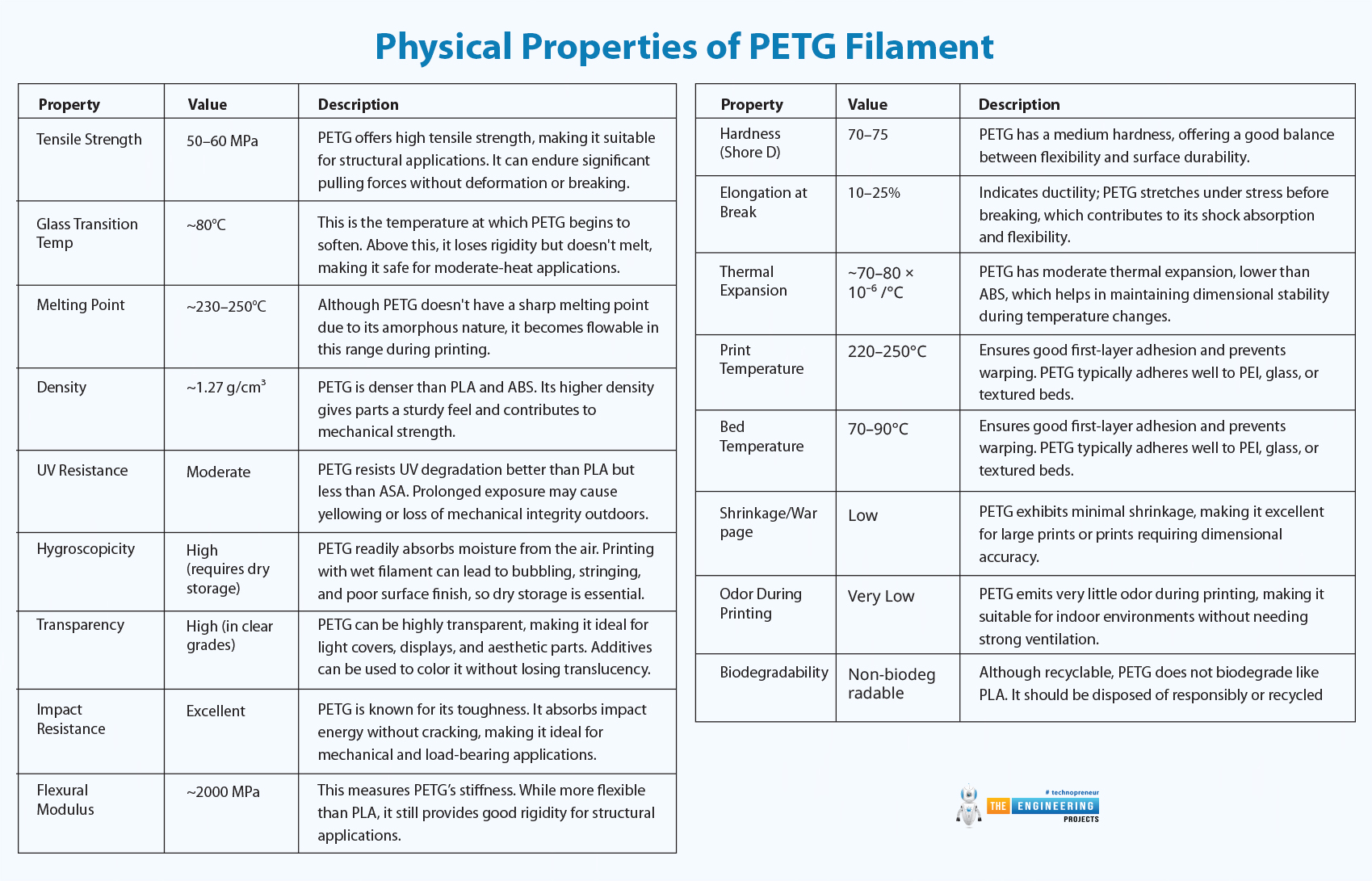

Physical Properties of PETG Filament:

Property |

Value |

Description |

Tensile Strength |

50–60 MPa |

PETG offers high tensile strength, making it suitable for structural applications. It can endure significant pulling forces without deformation or breaking. |

Glass Transition Temp |

~80°C |

This is the temperature at which PETG begins to soften. Above this, it loses rigidity but doesn't melt, making it safe for moderate-heat applications. |

Melting Point |

~230–250°C |

Although PETG doesn't have a sharp melting point due to its amorphous nature, it becomes flowable in this range during printing. |

Density |

~1.27 g/cm³ |

PETG is denser than PLA and ABS. Its higher density gives parts a sturdy feel and contributes to mechanical strength. |

UV Resistance |

Moderate |

PETG resists UV degradation better than PLA but less than ASA. Prolonged exposure may cause yellowing or loss of mechanical integrity outdoors. |

Hygroscopicity |

High (requires dry storage) |

PETG readily absorbs moisture from the air. Printing with wet filament can lead to bubbling, stringing, and poor surface finish, so dry storage is essential. |

Transparency |

High (in clear grades) |

PETG can be highly transparent, making it ideal for light covers, displays, and aesthetic parts. Additives can be used to color it without losing translucency. |

Impact Resistance |

Excellent |

PETG is known for its toughness. It absorbs impact energy without cracking, making it ideal for mechanical and load-bearing applications. |

Flexural Modulus |

~2000 MPa |

This measures PETG’s stiffness. While more flexible than PLA, it still provides good rigidity for structural applications. |

Hardness (Shore D) |

70–75 |

PETG has a medium hardness, offering a good balance between flexibility and surface durability. |

Elongation at Break |

10–25% |

Indicates ductility; PETG stretches under stress before breaking, which contributes to its shock absorption and flexibility. |

Thermal Expansion |

~70–80 × 10⁻⁶ /°C |

PETG has moderate thermal expansion, lower than ABS, which helps in maintaining dimensional stability during temperature changes. |

Print Temperature |

220–250°C |

The ideal nozzle temperature range ensures smooth extrusion and proper bonding between layers. Overheating can cause stringing; underheating causes poor flow. |

Bed Temperature |

70–90°C |

Ensures good first-layer adhesion and prevents warping. PETG typically adheres well to PEI, glass, or textured beds. |

Shrinkage/Warpage |

Low |

PETG exhibits minimal shrinkage, making it excellent for large prints or prints requiring dimensional accuracy. |

Odor During Printing |

Very Low |

PETG emits very little odor during printing, making it suitable for indoor environments without needing strong ventilation. |

Biodegradability |

Non-biodegradable |

Although recyclable, PETG does not biodegrade like PLA. It should be disposed of responsibly or recycled |

Material Composition and Characteristics:

The Structure and Makeup of Molecules:

The PETG material is made from PET, a semicrystalline polyester used in both food packaging and containerized drinks. PET is rather stiff in its original state, except when stretched or exposed to different temperatures, but chemicals do not easily damage it.

This is fixed by adding glycol during the making of PETG. Molecules in glycol-modified PET form an amorphous structure as glycol disrupts the crystals within the polymer chains. Because crystals are no longer present, the material gains greater transparency, greater stretch, and improved impact strength.

Enhanced Mechanical Properties:

The glycol modification also significantly improves PETG's mechanical properties. Lower brittleness means the material resists brittleness and can support more strain before it fails. It still has high tensile strength, and it also has better elongation at break than PLA, so it is feasible to create more durable prints.

This uncommon rigidity-flexibility balance renders PETG suitable for both dynamic and static components in prototype making and engineering. The ability of the material to absorb energy without loss of strength makes it suitable for impact or mechanically loaded components.

Thermal Stability and Behavior:

PETG has better heat resistance than PLA, with a glass transition temperature (Tg) of around 80°C. Although less heat-resistant than ABS, PETG's dimensional stability is good enough for most functional purposes. Its amorphous nature guarantees minimal shrinkage and warping, excellent layer adhesion, and dimensional stability when 3D printed.

Theoretically, the thermal characteristics of PETG are due to the incorporation of glycol units and regularity in the backbone that brings about thermal flexibility without compromising structure.

Chemical Resistance:

PETG is also very good at resisting chemicals. Because it stands up to attack from various chemicals, rubber is well-suited for use in medical, industrial, and consumer areas.

Fat can resist chemicals due to its ester groups, which do not react, and because its molecules are packed close together. When exposed to chemicals, PETG is resistant to damage and maintains its durability.

Optical Properties and Surface Finish:

The glycol modification of PETG gives it a highly transparent, glossy material. The amorphous structure minimizes light scattering, allowing transparent parts with excellent appearance. This makes PETG suitable for applications requiring transparency or translucency, such as:

Protective covers

Light diffusers

Medical devices with visible markers

Moreover, PETG's smooth surface finish requires minimal post-processing to look professional, contributing to its appeal for consumer products.

Printability and Processing Factors:

PETG's good melt flow and low warping properties result from its molecular structure. The viscosity of the polymer at extrusion temperatures creates smooth filament flow and good layer adhesion. PETG bonds well to 70-90°C heated print beds and usually needs a heated bed, but not an enclosed chamber.

Theoretically, the balance between the mobility of the polymer chain and intermolecular forces results in stable extrusion with no stringing or clogging when printing conditions are optimized.

Environmental Impact and Recycling:

Non-biodegradable like PLA but recyclable, PETG can be re-melted and reformed without adverse degradation due to its chemical stability and thermoplastic nature, and thus produces less environmental waste. Closed-loop recycling systems in development contribute to the sustainability profile of PETG.

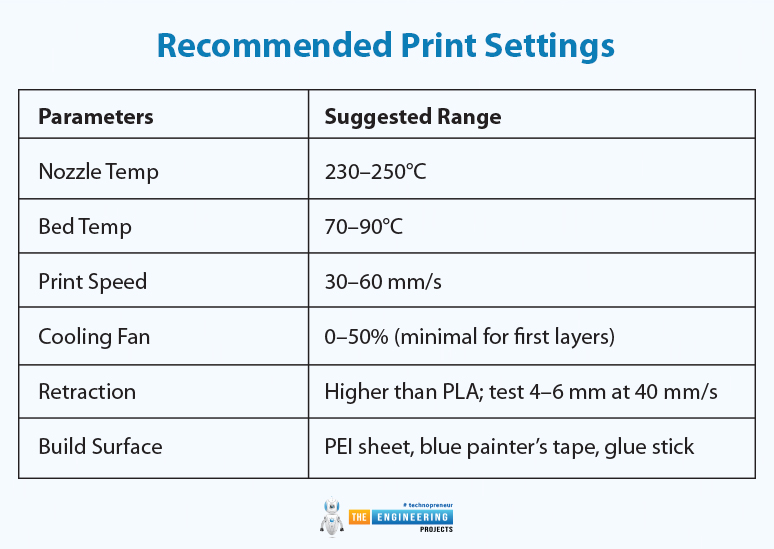

Printing Settings and Best Practices:

Recommended Print Settings:

Parameters |

Suggested Range |

Nozzle Temp |

230–250°C |

Bed Temp |

70–90°C |

Print Speed |

30–60 mm/s |

Cooling Fan |

0–50% (minimal for first layers) |

Retraction |

Higher than PLA; test 4–6 mm at 40 mm/s |

Build Surface |

PEI sheet, blue painter’s tape, glue stick |

Tips for Better Results:

Dry your filament before printing (use a filament dryer or oven at ~65°C for 4–6 hours).

Increase retraction and tweak the temperature to reduce stringing.

Use a glue stick or separator to avoid print bed damage from over-adhesion.

Cool slowly; sudden cooling can cause cracking in thicker parts.

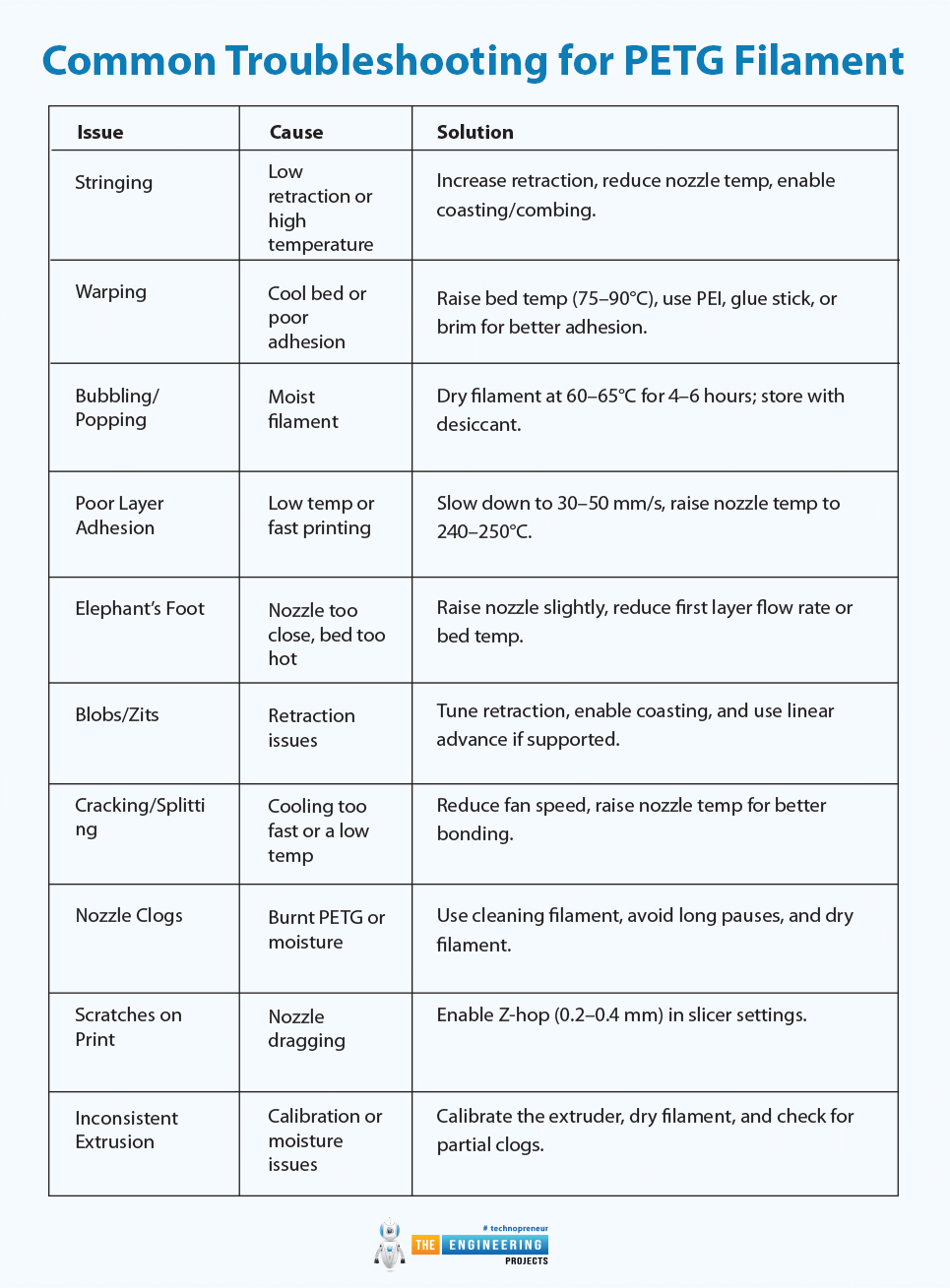

Common Troubleshooting for PETG Filament:

Issue |

Cause |

Solution |

Stringing |

Low retraction or high temperature |

Increase retraction, reduce nozzle temp, enable coasting/combing. |

Warping |

Cool bed or poor adhesion |

Raise bed temp (75–90°C), use PEI, glue stick, or brim for better adhesion. |

Bubbling/Popping |

Moist filament |

Dry filament at 60–65°C for 4–6 hours; store with desiccant. |

Poor Layer Adhesion |

Low temp or fast printing |

Slow down to 30–50 mm/s, raise nozzle temp to 240–250°C. |

Elephant’s Foot |

Nozzle too close, bed too hot |

Raise nozzle slightly, reduce first layer flow rate or bed temp. |

Blobs/Zits |

Retraction issues |

Tune retraction, enable coasting, and use linear advance if supported. |

Cracking/Splitting |

Cooling too fast or a low temp |

Reduce fan speed, raise nozzle temp for better bonding. |

Nozzle Clogs |

Burnt PETG or moisture |

Use cleaning filament, avoid long pauses, and dry filament. |

Scratches on Print |

Nozzle dragging |

Enable Z-hop (0.2–0.4 mm) in slicer settings. |

Inconsistent Extrusion |

Calibration or moisture issues |

Calibrate the extruder, dry filament, and check for partial clogs. |

Application of PETG:

PETG is found to be used on a truly global scale and is often chosen for its impressive workability and flexibility, and is probably one of the best all-around materials for functional, commercial, and industrial purposes. Tear and impact resistance, chemical and UV resistance, transparency, and printability are all features to make PETG one of the most flexible materials across a wide range of contexts.

Functional Prototyping:

PETG's print consistency, impact resistance, and dimensional stability are all great qualities to possess as a functional prototype material. It is widely used by engineers and designers in iterative design workflows to test form, fit, and function. PETG is likewise highly resistant to mechanical stress, enabling simulation of real-life conditions and mechanical stress testing of parts before final manufacture.

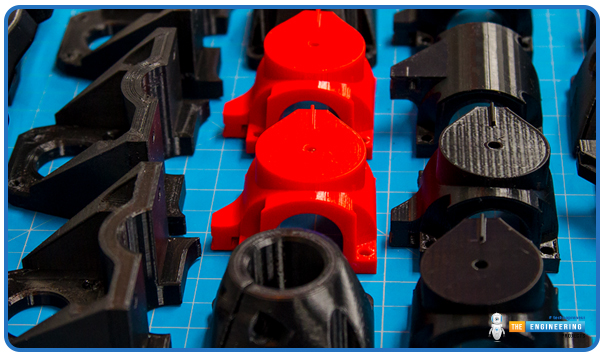

Mechanical Parts:

Because of its impact resistance and moderate flexibility, PETG is well-suited for the production of durable mechanical parts such as brackets, gears, spacers, custom fixtures, and even robotic components. Its wear-and-tear resistance without cracking renders it a convenient alternative to ABS in most cases.

Medical Equipment:

During times of public health crisis, e.g., the COVID-19 pandemic, PETG was widely used to manufacture face shields, mask retainers, test tube trays, and other non-life-sustaining medical products. Its transparency to light, safety, and sterilizability are all reasons why it is an excellent choice for the like applications.

Containers and Bottles:

PETG is chemical-resistant in its natural form and can be processed to become food-safe, so it is utilized to develop custom fluid containers, storage bottles, and food packaging. It is a favorite in laboratories and home kitchens at smaller scales for developing long-lasting and reusable solutions for packaging.

Lighting and Electronics:

The clarity and glossy surface finish of PETG give it the best-fit use in functional and decorative parts like LED enclosures, light diffusers, sensor housing, and electronic enclosures. It offers a combination of aesthetic appeal with electrical insulation to provide value added both in function and form in design.

Conclusion:

PETG (Polyethylene Terephthalate Glycol-modified) is already one of the most reliable and most durable filaments for 3D printing. When considering programmatic gut of printable materials such as PLA or characteristics of strength and toughness such as ABS, PETG is essentially your best of both worlds, combining excellent printability with mechanical qualities and decent chemical resistance. Its superior layer adhesion, impact strength, and minimum warping properties have made it a favorite with professionals and hobbyists alike.

From functional proof of concept prints to mechanical components, enclosures, and even end-use products, PETG excels in a broad variety of applications. Its impact resistance to create strong, good-looking, and clear parts still makes it popular in use within engineering, product development, and consumer product markets.

With appropriate treatment, above all, with moisture management and print parameters, PETG is a very reliable material for everyday application or delicate development work. As the demand for heavy-duty and top-of-the-line 3D printed components increases, PETG is a material that squarely exceeds the modern standards of today's designers, engineers, and makers.

3D Printing

3D Printing xeohacker

xeohacker 0 Comments

0 Comments