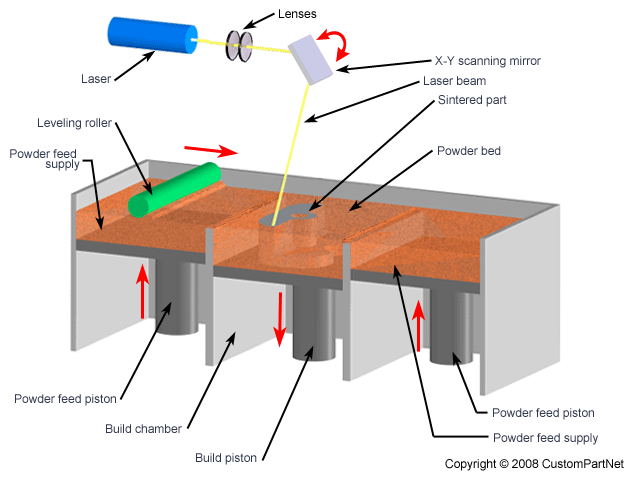

How does Selective Laser Sintering work?

SLS uses a nylon or polyamide powder which is spread successively in thin layers with a high-powered laser that selectively sinters the powder according to data derived from digital models. This process is repeated layer after layer, binding the powdered material together to produce a final, firm structure. Excess powder is removed manually to reveal the final shape before bead blasting is applied to further remove powder residue.

What is SLS used for?

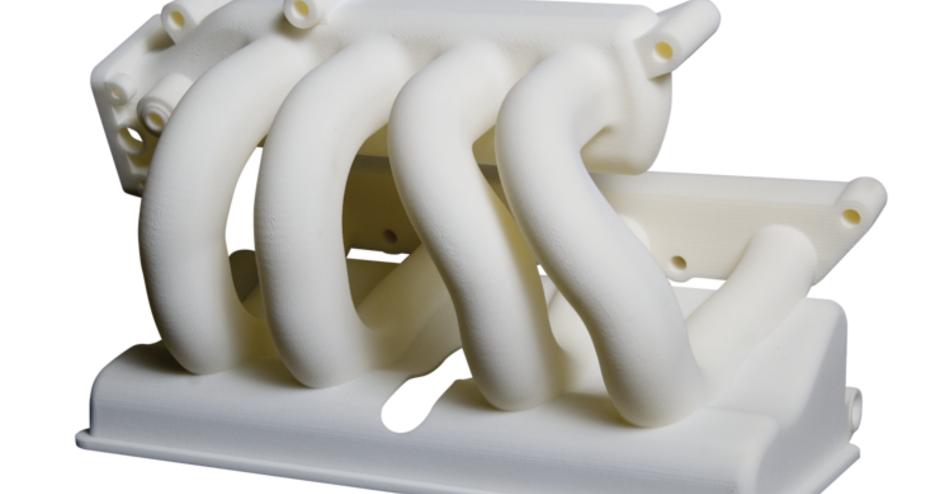

SLS is used for high productivity manufacturing tasks thanks to the laser’s high power and capability to scan quickly and accurately. It is a technology able to produce durable prototypes from a broad range of nylon-based materials, and it is also capable of printing independently moving parts in a single build. SLS is known as the go-to technology for producing complex shapes. It does not require a support structure and utilises unused powder to further add to its strength. In industries where lightweight material is imperative to a successful design (for example, aircraft building and automotive) SLS printed parts are invaluable.What kind of products are made with SLS?

Being able to produce high strength products at a low volume, using different materials, like glass, plastic, metal and ceramics, means SLS printing is used to create many different tailored products. Medical and dentistry products such as prosthetics, hearing and dental aids are made using SLS. SLS is often utilised in industries where high-volume production is not required, for example, end-use parts for aeroplanes where only small quantities are needed on an infrequent basis. Businesses are able to store the digital files needed for SLS printing inexpensively and reproduce designs as and when required, instead of spending money on the expensive storage of moulds used in traditional manufacturing.Benefits of Selective Laser Sintering

SLS has an impressive number of benefits. Primarily, it is a technology suitable for high productivity and quick turnaround times of less than 24 hours. The nylon powder used needs only a very brief exposure to the laser for sintering, making the process faster than other technologies. The associated cost of moulds is not required meaning it is ideal for rapid prototyping. Along with these benefits, SLS is a self-supporting technology, affording greater scope for more complex designs. This differs from the more widely adopted FDM (Fused deposition modelling) printing and stereolithography (SLA) which require structure support during printing. Laser adhesion is also stronger with SLS printing and the porous surfaces created to allow for a very effective dyeing process to final shapes and products.

Tutorials

Tutorials zoyebella

zoyebella 0 Comments

0 Comments