Hi readers! I hope you are having a great day and want to learn something new. Developing an effective engine emission control system makes every puff of smoke from your engine a story of power, efficiency, and a cleaner planet. Today, the topic of discourse is the engine’s emission control system.

The primary role of the engine emission control system is to prevent the release of toxic pollutants into the atmosphere during fuel combustion. It works together with fuel injection, the ignition timing, and exhaust treatment technologies so that it complies with the government regulations as far as the environment is concerned. Its principal parts comprise of catalytic converter, oxygen sensors, the exhaust gas recirculation (EGR) system, and the onboard diagnostics (OBD). The different emission control devices regulate and correct the proportion of air-fuel to maximize the decrease of the emissions related to nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC).

Today, the modern systems are usually fully integrated in the ECU, which receives input from all relevant sensors and duly makes adjustments based on the results for optimal performance and keeps doing so in real-time. In the case of fuel injection, for instance, only the right amount of fuel is injected directly into the combustion chamber so as to ensure complete burning to reduce emissions further. Error codes such as p130 may be thrown for anything from a misfire to emission control problems, thereby enabling timely maintenance.

Environmental and emission laws are no longer the only reason for emission control systems; now, the inability to achieve the best fuel economy and engine output with minimum environmental consequences is also stated as an essential factor. An emission control system that is well maintained guarantees a cleaner operation, prolonged service life of the engine, and a lower carbon footprint to the advantage of both the operator and the environment.

Here, you will find emission control, fuel injection, P130 code issues, and components ensuring cleaner, more efficient vehicle performance. Let’s dive.

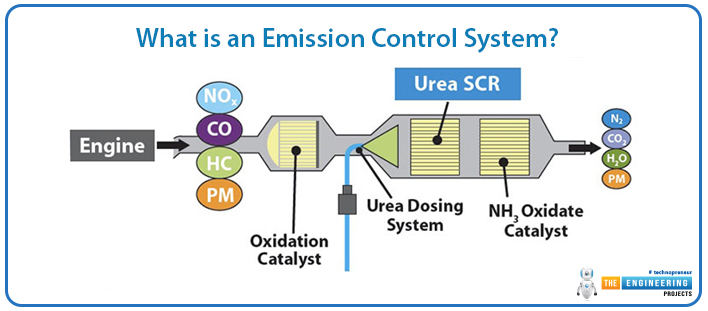

What is an Emission Control System?

It can be defined as a system of special components and subsystems installed in a car that regulates excessively damaging exhaust streams resulting from the combustion of fuel. The main aim of the system is to transform toxic gaseous outputs like nitrogen oxides (NOx), carbon monoxide (CO), and unburnt hydrocarbons into relatively harmless outputs in the form of gases before releasing them to the atmosphere through the exhaust pipe.

Objectives of the Emission Control System:

To reduce NOx, CO, and Hydrocarbons: The reduction of these pollutants is directly related to the improvement of air quality.

To Ensure Engine Efficiency, Combustion optimization must be done without compromising emissions; thus, clean fuels will mean more economical fuels.

Prevent Environmental Pollution: The Aim will be to safeguard the atmosphere and eventually reduce the development of smog.

Keep standards: Meet global regulations such as the EPA and EURO 6.

Enabling real-time monitoring and diagnostics: Advanced sensors that detect problems instantly and allow for a fast response to trouble codes, such as p130.

This system is very relevant where modern vehicles are concerned; in fact, it has shown one way in which performance coexists with environmental responsibility.

Importance of Combustion in Emission Formation:

The internal process of the engine involves combining the fuel with air, lighting it on fire, and utilizing the energy to drive the vehicle through a process called combustion. Ideally, this must be full and efficient, and with inoffensive products like water vapor and carbon dioxide. Nevertheless, a lot of toxic emissions are generated as a result of incomplete or inefficient combustion.

Carbon monoxide (CO): This is a poisonous colorless gas that arises when there is incomplete combustion of the fuel.

Hydrocarbon (HC): Fuel-derived remnants, fumes that are burned and result in unjustified air pollution and smog.

Nitrogen oxides (NOx): They are formed when the intensity of combustion temperature is high and causing acid rain and pulmonary disorders.

Particulate matter (PM): These are extremely small soot particles, particularly in diesel engines, that are disastrous not only to an individual but also to the environment.

The slightest inconsistency at this stage, like timing, delivery error of fuel, or ignition impairments, can have a great influence on the emissions levels. Engine misfire is a predominant cause that most adversely affects the burn cycle of the air-fuel mixture. Real-time monitoring systems detect these malfunction situations as they occur, typically causing the triggering of diagnostic trouble codes like the P130 code , which generally refers to an issue of misfire detection. Early resolution of problems in real-time leads to cleaner emissions and increased life expectancy and performance of the engine.

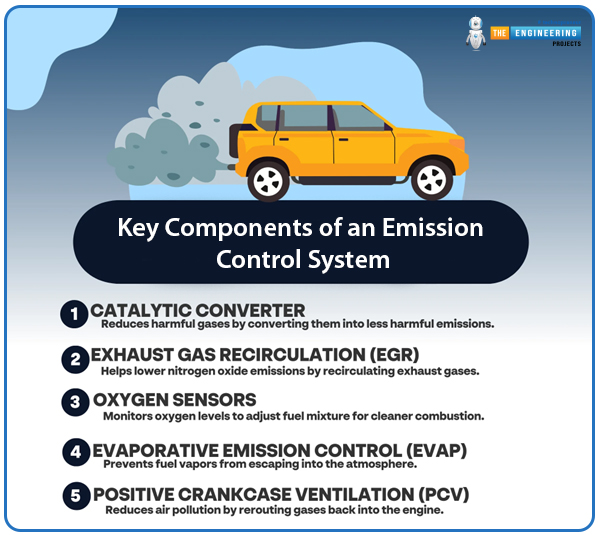

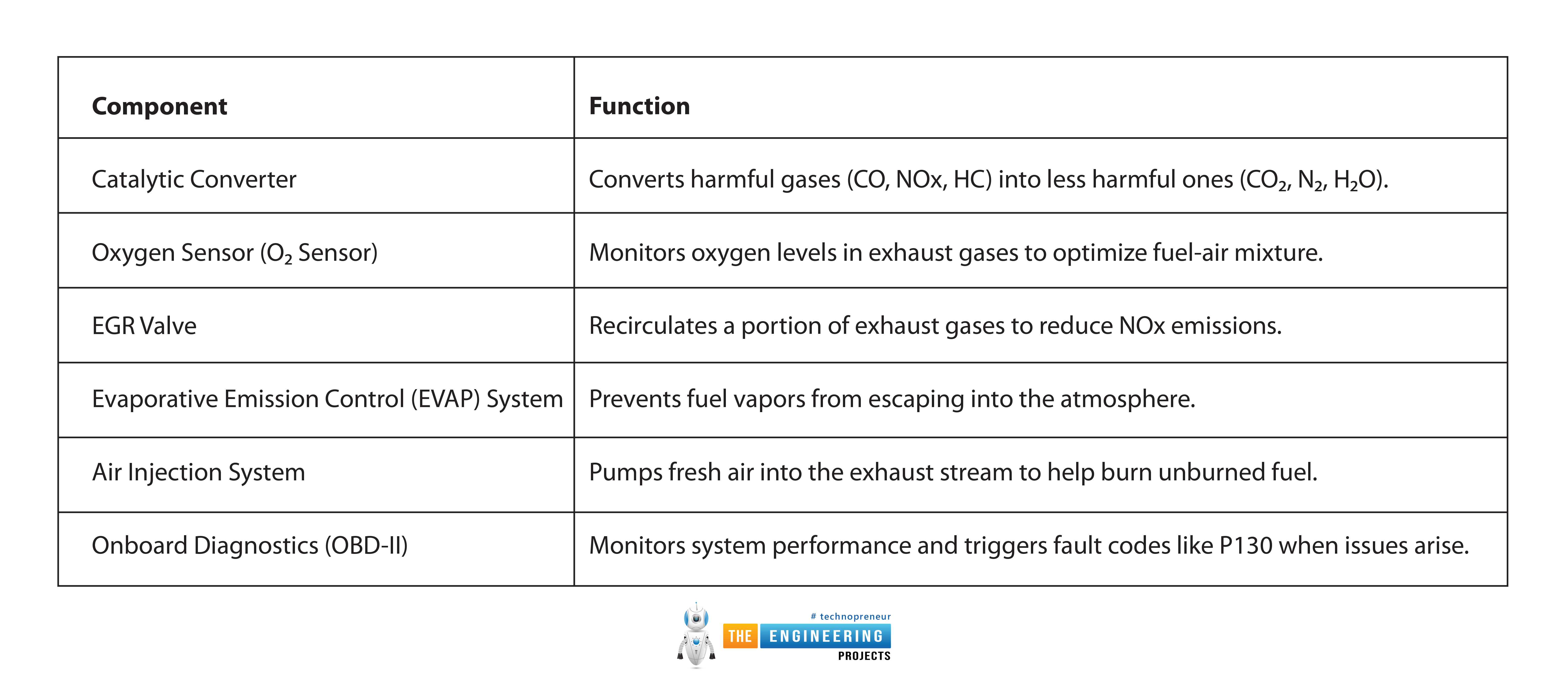

Key Components of an Emission Control System:

Component |

Function |

Catalytic Converter |

Converts harmful gases (CO, NOx, HC) into less harmful ones (CO₂, N₂, H₂O). |

Oxygen Sensor (O₂ Sensor) |

Monitors oxygen levels in exhaust gases to optimize fuel-air mixture. |

EGR Valve |

Recirculates a portion of exhaust gases to reduce NOx emissions. |

Evaporative Emission Control (EVAP) System |

Prevents fuel vapors from escaping into the atmosphere. |

Air Injection System |

Pumps fresh air into the exhaust stream to help burn unburned fuel. |

Onboard Diagnostics (OBD-II) |

Monitors system performance and triggers fault codes like P130 when issues arise. |

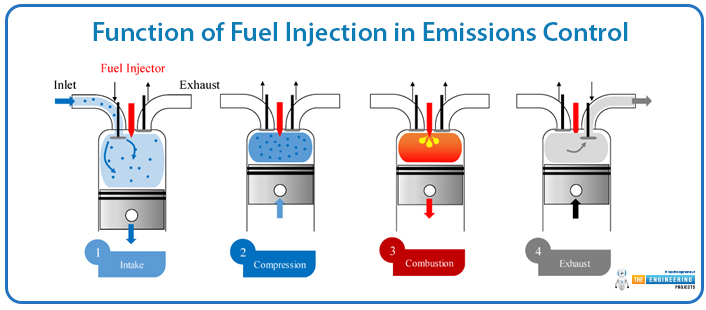

Function of Fuel Injection in Emissions Control:

The fuel injection system must deliver ideal portions of fuel to be combusted productively to limit exhaust. The fuel injector sprays high-pressure fuel in the combustion chamber or into the intake manifold, where it is atomised to mix with the air. This guarantees that the substance of benzene burns completely and, therefore, results in minimum emissions of toxic pollutants.

How It Works:

Controlled by the ECU, the injectors open and close within milliseconds, metering fuel precisely concerning load, speed, and temperature.

Fuel Injection Types:

Port Fuel Injection: Injects fuel into the intake port just before it enters the combustion chamber.

Gasoline Direct Injection: Injects fuel directly into the combustion chamber, thereby gaining efficiency and power.

Common Rail Diesel Injection: Also known as CRDI, which functions by giving very fine atomization, leading to reduced soot and NOx emissions.

Fuel Injection and Emissions:

If the injectors are faulty, combustion may be incomplete, leading to the formation of black smoke and excess hydrocarbons or elevated NOx. If they trigger diagnostic trouble codes, injectors can be found to trigger trouble codes like the P2099 code .

Air-Fuel Ratio: The Balancing Act

This requires that the air-fuel ratio be monitored correctly to achieve total combustion and experience a reduced amount of exhaust gases. In the case of gasoline engines, this stoichiometric ratio would be 14.7:1, or that 14.7 parts of the air are needed to one part of the fuel. Lean air-fuel mixtures of 16:1 to 22:1 have been made possible in the manufacturing of diesel engines.

Going beyond these exemplary ratios could result in the following serious consequences:

Rich mixture: Increase in CO and HC emissions.

Lean mixture: Engine knocking and increased NOx emissions are experienced.

Both of these abnormalities may call for a Diagnostic Trouble Code, like a P130 code for misfires.

The Engine Control Unit (ECU) keeps this on even keel using sensor inputs from:

Mass Air Flow (MAF) Sensor

Manifold Absolute Pressure (MAP) Sensor

Throttle Position Sensor (TPS)

Oxygen (O₂) Sensors

6. Unraveling P130 Diagnostics: The Misfire Signal

The P130 code indicates a type of OBD-II problem that concerns misfires due to ignition or combustion detection. It has the effect of "changing" the air-fuel mixture, making engine operation less efficient, and increasing emissions.

What Does It Mean?

Depending on vehicle make, it may indicate:

Ignition coil malfunction

Misfire detection inhibited

Knock control error

Combustion irregularity affecting emission monitoring

Common Causes:

Faulty spark plugs or ignition coils

Poor fuel quality

Vacuum leaks

Bad oxygen sensors

Fuel injector clogging

EGR or catalytic converter failure

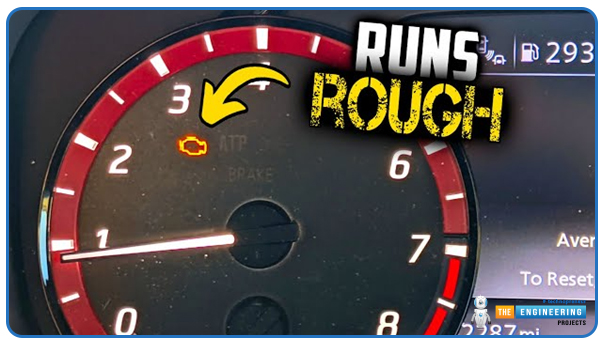

Symptoms:

Check Engine Light

Rough idle or engine shaking

Lower fuel efficiency

Failed emissions test

Elevated tailpipe emissions

How to Fix It:

Scan using a professional OBD-II scanner

Replace faulty spark plugs/ignition coils

Check for vacuum leaks

Clean or replace injectors

Reset the ECU after repairs

7. Emission Testing and Compliance:

Several regions require annual or biennial emissions testing to ensure that vehicles adhere to pollution control standards. A stored P130 code could lead to:

Inspection failure

Fines or denying registration

Repairs are required before retesting

Readiness monitors contribute significantly to compliance. These monitors are self-tests that validate whether systems such as the catalytic converter, EVAP system, and O₂ sensors are functioning. A flagged misfire condition due to the P130 code often prevents these monitors from going into "ready," thus preventing certification.

By knowing and acting upon the P130 code in a timely fashion, vehicle owners can collectively ensure that their vehicles will run smoothly, pollute less, and stand in legally while not incurring unwanted downtime and penalties.

8. The Case Study in the Real World:

Car: 2016 BMW 3-series

Problem: Rough idling, no speed

Code Thrown: P130A (a version of P130 code)

During the workshop was coming a BMW 3-Series came with a tormented idle and visibly poor acceleration. The fault code P130A was identified with a scan, which can typically signal a misfire or fuel delivery error. After additional diagnosis using a commercial scan tool, it was determined that the upstream oxygen (O2) sensor was intermittently failing.

Owing to the inaccurate data being indicated by the O2 sensor, there was no way in which the ECU could compute the air-fuel ratio correctly. Consequently, there was a poor combustion process. Also, the ECU had partially disabled misfire monitoring because of a lack of sensor data; therefore, none of the misfire codes were recorded, either, though clearly the functionality was affected.

Fix:

The faulty upstream sensor O2 was replaced with a certified part.

Re-adaptation to ECU was done to reset learned parameters.

All the codes were removed, and the car passed an emissions test.

Lesson:

A comparatively small sensor malfunction can have a knock-on effect on performance, fuel consumption, and emissions compliance.

9. High Emission Technology:

Contemporary automobiles have high-tech devices to comply with the pollution standards. The ECU closely monitors these systems, and when one of them fails, it may result in trouble codes like P130A.

The concept of Diesel Particulate Filters (DPFs):

Diesel fumes.

Regeneration cycles should be used to use up the soot and maintain flow efficiency.

A dirty DPF raises exhaust backpressure, thereby reducing engine performance and increasing emissions.

Selective Catalytic Reduction (SCR):

Frequent in the newer diesel engines.

Incorporates the technology of converting harmful amounts of nitrogen oxides (NOx) into harmless nitrogen and water by use of urea (AdBlue) injection.

Misfunctions may give rise to excessive NOx emissions and cause fault codes.

Variable Valve Timing (VVT):

Timing the opening and closing of intake and exhaust valves to maximise ignition.

Enhances power output accompanied by decreasing fuel consumption and CO2 emissions.

Start-of-service replacement of faulty VVT actuators or sensors may lead to drivability problems and preliminary emissions failures.

Start-Stop Systems:

Automatically shut down the motor in idle positions, fuel-saving, and reduce CO2 emissions.

Uses accurate sensor feedback to quickly and smoothly relaunch.

Problems will lead to comfort complaints and test failures on the emission tests.

10. Emission Control In The Future:

Predictive Diagnostics and AI

AI will be used by future onboard systems to evaluate driver behavior, the environment, and sensor patterns. That will allow predictive maintenance by notifying the driver before a sensor, catalytic converter, or DPF breaks, avoiding the expensive repairs and unforeseen downtime.

Electrification:

Although electric vehicles (EVs) do not emit any tailpipe emissions at all, hybrid vehicles continue to use combustion engines. Such engines need a high level of emission control, and therefore diagnostics will have its dependencies in the foreseeable future. The hybrid powertrains especially require an increased, complicated ECU to achieve compliance with emissions.

Cloud-Based OBD:

CVT will enable immediate uploads of diagnostics data, such as emissions-consuming codes, to the central servers, such as the p130 code. This will facilitate remote monitoring, fault detection early enough, and booking of services without necessarily waiting until the vehicle fails a working check.

Conclusion:

This emission control system of an engine is a highly sophisticated arrangement that checks the exhaust gases to enhance combustion and reduce environmental impact. Through these emission systems, vehicles can run well while complying with strict emission regulations as it assist with the injection of just the right amount of fuel, with efficient treatment of the exhaust, and appropriate sensors for continuous monitoring.

P130 code and other such diagnostic codes act as an advanced warning system; they warn of the existence of a possible fault within the system. Failure to act on such alarms will lead to poor performance, wastage of fuel, generation of lots of emissions, and costly repairs. Thus, early detection and mitigating measures should be put in place to save not only the health of the vehicle but also the environment in terms of compliance.

But for drivers, mechanics, and managers, it's not good maintenance as such in interpreting fault codes-the thing is beyond human and has to do with full-blown atmosphere-saving and legal repercussions. Since improvement is under the wing of greener innovations and stricter emission laws, training in managing and maintaining emission control systems remains an indisputable asset for achieving cleaner, more sustainable transportation.

Control Systems

Control Systems xeohacker

xeohacker 0 Comments

0 Comments