I hope you are doing well and exploring new things daily. Today's topic is Metal 3D Printing and its future in the world of technology.

Metal 3D printing, or metal additive manufacturing, refers to adding parts layer by layer, processes of which include laser melting, electron beam fusion, and binder jetting. This method requires less waste and usually comes out with direct production from digital designs while producing lightweight structures and complex geometries. Its application is widespread: Aerospace, automotive, and healthcare industries continuously make functional prototypes for production parts, tooling, and repairs.

Innovations in materials, processes, and scalability are driving the future of metal 3D printing.

Specialized metal alloys and composites are expanding applications, while hybrid systems combining additive and subtractive methods improve precision and reduce post-processing. Multi-laser systems and faster deposition rates enhance production speeds, making mass production feasible. This transformative technology would reconfigure manufacturing entirely by optimizing the designs and quality control through artificial intelligence and machine learning, ensuring sustainability at all costs.

This article will cover the future trends of metal 3D printing. Let’s start.

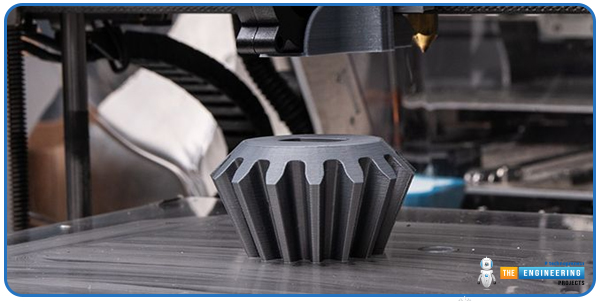

How Metal 3D Printing Works:

Design: An appropriate CAD is taken and further modelled into 3D format, and exported appropriately into the required format.

Material Selection: Depending on desired properties, the metal powders could be either titanium or stainless steel.

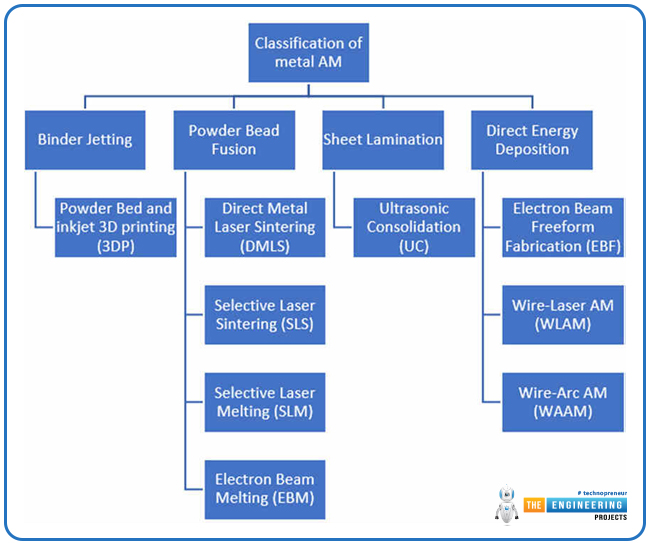

Printing Process: Methods include Powder Bed Fusion (laser melting powder), Directed Energy Deposition (laser deposition), and Binder Jetting (binder bonding followed by sintering).

Layering: Metal layers are melted and solidified layer by layer.

Post-processing: Heat treatment, surface finishing, and machining enhance properties and accuracy.

Metal 3D printing makes it possible to print parts that are otherwise impossible to be printed using conventional manufacturing methods.

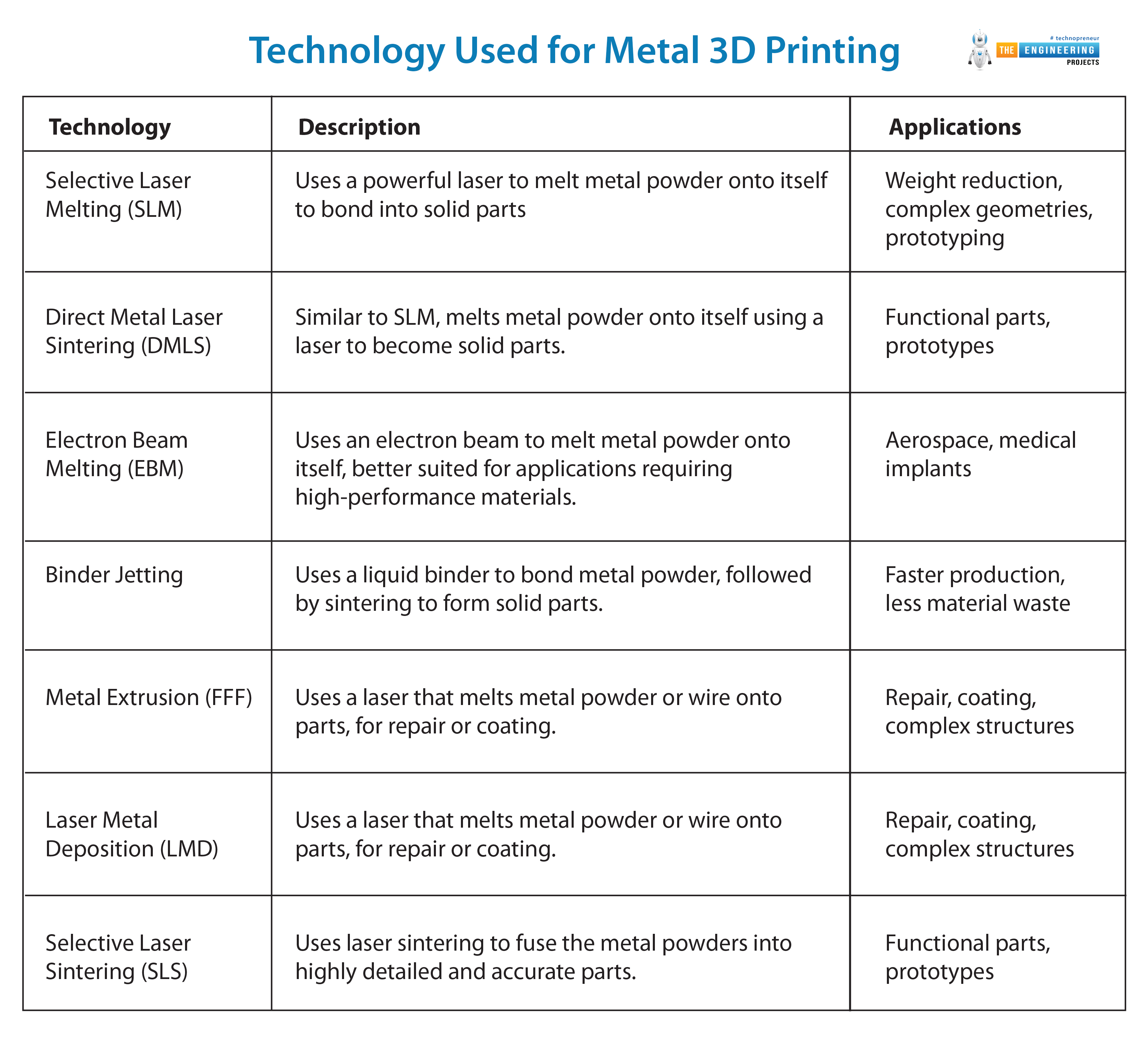

Technology Used for Metal 3D Printing:

Technology |

Description |

Applications |

Selective Laser Melting (SLM) |

Uses a powerful laser to melt metal powder onto itself to bond into solid parts |

Aerospace, medical, automotive |

Direct Metal Laser Sintering (DMLS) |

Similar to SLM, melts metal powder onto itself using a laser to become solid parts. |

Functional parts, prototypes |

Electron Beam Melting (EBM) |

Uses an electron beam to melt metal powder onto itself, better suited for applications requiring high-performance materials. |

Aerospace, medical implants |

Binder Jetting |

Uses a liquid binder to bond metal powder, followed by sintering to form solid parts. |

Faster production, less material waste |

Metal Extrusion (FFF) |

Uses powders of metal mixed with plastic filament, heated, and extruded to shape parts. |

Prototypes, low-volume parts |

Laser Metal Deposition (LMD) |

Uses a laser that melts metal powder or wire onto parts, for repair or coating. |

Repair, coating, complex structures |

Selective Laser Sintering (SLS) |

Uses laser sintering to fuse the metal powders into highly detailed and accurate parts. |

Functional parts, prototypes |

Emerging Trends in Metal 3D Printing:

Several new drivers for its future include material development, hybrid systems, and AI integration combined with higher printing speeds as well as continued improvements in sustainability.

New Metal Alloys and Composites Development:

A big advance will be the generation of special alloys and metal matrix composites. Inconel 718 and Ti-6Al-4V are the most utilized alloys for metal 3D printing in making high-performance lightweight, strong components. These kinds of alloys have found wide usage in aerospace and healthcare industries that have extreme demands in terms of exceptional properties required from the material. The second area of metal matrix composites, wherein metals are bonded to ceramic particles, offers better strength, thermal stability, and resistance to wear for metals so that the entire range of applications for 3D printed metals is becoming increasingly applicable.

Hybrid Manufacturing Systems:

Hybrid manufacturing systems, which embrace additive and subtractive processes, are gradually gaining acceptance in the market. A hybrid manufacturing system combines the capabilities of 3D printing, mainly design freedom with conventional machining and accuracy. Such hybrid systems, for instance in aerospace and car manufacturing, allowed the production of complex geometries with fine surface finishes. Indeed, switching the process between additive and subtractive processes in the same system is revolutionizing production speed and precision.

AI and Machine Learning Integration:

AI and machine learning are transforming metal 3D printing through the optimization of real-time process monitoring, defect detection, and print parameter optimization. AI algorithms can predict and correct issues like warping or under-extrusion before they occur, which would ensure constant quality and efficiency in the print. Machine learning systems can also process huge amounts of data to optimize the printing parameters, thereby maintaining better control over the production process.

Enhanced Printing Speed and Efficiency:

It enables improved speed and efficiency of printing metal: metal 3D printing can go much faster because of developments in high-power lasers and electron beams. Therefore, reduced production time can be ensured while ensuring good output. With HSS and CLIP technologies that improve on printing speed and efficiency, there's even prototyping, up to mass production that could be very practical in metal 3D printing in terms of large-scale industrial use.

Sustainability in Metal 3D Printing:

Sustainability in Metal 3D Printing Sustainability has always been a focus area, and there is marked progress in material efficiency and energy usage. Metal 3D printing doesn't waste much because it collects its used metal powders and further limits the material required for production. Additive manufacturing requires only so much material that is required to produce each part. This means that the waste generated is even less than in subtractive manufacturing. All these developments help create more sustainable, resource-efficient manufacturing practices.

Challenges of Metal 3D Printing:

High Initial Costs:

The highest investment in metal 3D printing is due to equipment and materials. SLM and DED machines that are used in metal additive manufacturing cost hundreds of thousands of dollars. The powder used for such processes is very expensive, and most small-scale businesses cannot afford such technology.

Material limitations and availability:

Metal 3D printing is limited to the number of available metals for use. Alloys, for example, titanium, aluminum, and stainless steel are more commonly used; yet, metal varieties are not as extensive as conventional manufacturing methods. Also, high-quality metal powders are less consistent and may lead to inferior printed parts with less than optimal performance.

Post-processing needs:

Often, parts printed through metal 3D printing have to undergo major post-processing to acquire the desired surface finishes, dimensional accuracy, and mechanical properties. Among these processes include the removal of supports, heat treatment, and machining. This increases cost and production time. Post-processing steps may even eliminate some of the cost advantages that 3D printing affords.

Size and Scalability Limitations:

Metal 3D printers have smaller build sizes, thus making it unfeasible to print large parts in one process. Production scaling for a high volume in manufacturing is hard because metal 3D printing is a better fit for low volumes with high complexities rather than a mass production item.

Speed and Throughput:

PBF is one of the metal 3D printing processes that are much slower than conventional manufacturing. Layer by layer is one of the methods that take the most time; this is less desirable for high throughput applications where speed is of great importance.

Quality Control and Reliability:

Quality parts may be hard to ensure when there is variability in machine parameters, material inconsistency, or design flaws. Variability could result in defects and may affect the strength and performance of the part.

Future of Metal 3D Printing:

The future of metal 3D printing is going to be tremendous with immense change in its approach and processes. A whole new evolution in the production of metals for use in diverse industries like aerospace, automotive, healthcare, and manufacturing will unfold.

Advanced Material Development:

New materials are the heart of the drivers for more growth in the future for metal 3D printing. New superalloys and composites for high-performance applications, metal alloys, will always be found. The expansion into new materials provides new opportunities, where unique properties exhibit higher strength, as well as an increased level of resistance to corrosion and even heating. It will be expanded even further into a particular industry requirement like performance requirement.

AI and Machine Learning Integration:

This will change the game for the design and manufacturing process in metal 3D printing, integrating AI and machine learning into metal 3D printing. AI and machine learning could further enhance optimization to include real-time adjustments for improving print quality, speed, and efficiency. AI-based solutions can help in predicting part failure, material waste reduction, and increasing consistency in production.

More Automation and Hybrid Systems:

The increasing demand for efficiency will mark the increased automation in design and production in the future of metal 3D printing. Hybrid systems will merge traditional process manufacturing with additive processes, and larger, complex parts will be produced with significantly higher precision. This will lead to streamlining the workflow, reduce human errors, and increase the cost-effectiveness associated with metal 3D printing.

On-Demand and Decentralized Manufacturing:

Decentralization in manufacturing will happen through the development of metal 3D printing in the future. On-demand parts can be printed at not-too-large local 3D printing facilities without needing a long supply chain and huge factories. A more sustainable, agile manufacturing model will have fewer carbon footprints, shipping costs, and lead times associated with the traditional method.

Mass Customization:

The extremely customized, complex geometries that can be produced with metal 3D printing will make the mass customization concept very popular in all industries, especially for health and custom implants, as well as in aerospace with one-off bespoke parts. The capability to mass manufacture low-cost, high-precision custom components on demand will revolutionize the industries that rely on such complex designs.

Shaping the Future of Metal 3D Printing:

In shaping the future of metal 3D printing, the research community and industry have to take a series of steps:

Investment in Research and Development:

Continuing investment in R&D will be required to develop metal 3D printing. New materials, higher print speeds, and seamless integration into traditional manufacturing processes should be drivers of adoption. Expectations around innovation will be fueled by cooperation among industry leaders, universities, and government agencies.

Standardization and Quality Control:

Before it becomes a standard manufacturing process, the most important thing to be established is the standardization of processes and certifications for quality control. This will include benchmarks in material properties, build quality, and performance for printed parts. Clear standards would increase industry confidence and facilitate wider adoption.

Education and Skill Development:

With the growth of the 3D printing industry, with various metals being used in it, upgrading the skills of the workforce is a must. Universities, technical institutes, and companies have to take up the challenge of introducing specialized training programs for engineers, designers, and operators for additive manufacturing.

Encourage industry collaboration:

The collaboration of industries will speed up the development of metal 3D printing technologies. Companies can share best practices, optimize production methods, and expand the range of applications for 3D printing in various sectors by working together.

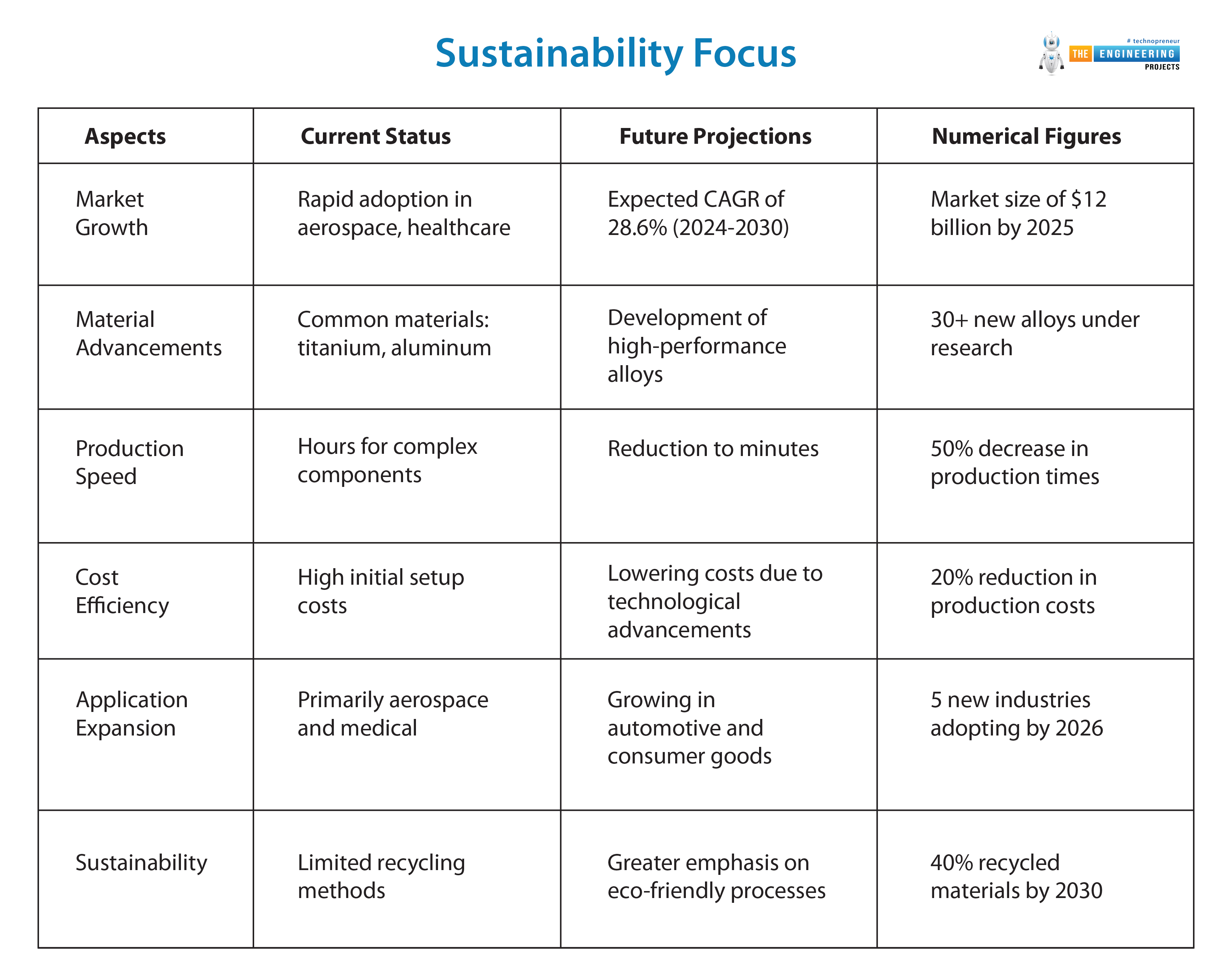

Sustainability Focus:

Sustainability will rule the future of metal 3D printing. It is that aspect that will determine the sustainable nature of technology, which gives much importance to recycling metal powders, generates very little waste in terms of material, and works on renewable sources of energy. Sustainability will play a key role in combating the environmental degradation associated with the process of production.

Aspects |

Current Status |

Future Projections |

Numerical Figures |

Market Growth |

Rapid adoption in aerospace, healthcare |

Expected CAGR of 28.6% (2024-2030) |

Market size of $12 billion by 2025 |

Material Advancements |

Common materials: titanium, aluminum |

Development of high-performance alloys |

30+ new alloys under research |

Production Speed |

Hours for complex components |

Reduction to minutes |

50% decrease in production times |

Cost Efficiency |

High initial setup costs |

Lowering costs due to technological advancements |

20% reduction in production costs |

Application Expansion |

Primarily aerospace and medical |

Growing in automotive and consumer goods |

5 new industries adopting by 2026 |

Sustainability |

Limited recycling methods |

Greater emphasis on eco-friendly processes |

40% recycled materials by 2030 |

Conclusion:

This revolutionizes the world of tech in opening new horizons into innovation, personalization, and sustainability with 3D metal printing capabilities for creating complex geometries with low waste generation while promoting on-demand production for various applications across the sectors of aerospace, automotive, and healthcare. Nevertheless, such opportunities cannot come for free; one encounters huge cost pressures, limitations of the types of materials being developed, and calls for standardization in practice. It offers greater design flexibility and rapid prototyping, thus improving product development cycles and shortening time-to-market.

Further drive is in efforts regarding metallic alloys, hybrid manufacturing systems, and AI integration, further enhancing the efficiency and precision of 3D printing. With these developments, metal 3D printing will increasingly substitute the traditional methods of manufacturing in many scenarios, thus increasing efficiency and decreasing costs while making it more sustainable for production. Metal 3D printing holds immense promise for changing global industries and pushing the technology envelope.

3D Printing

3D Printing xeohacker

xeohacker 0 Comments

0 Comments