I hope you are doing well and exploring new things daily. Today's topic is the working of Metal 3D Printing. It refers to the technique of creating a metal part directly from a digital design layer by layer.

Instead of subtractive material from a solid block like conventional manufacturing, metal additive manufacturing or metal 3D printing involves additive material addition in building up the object. This can give geometries with intricate designs and internal structures not easily achieved using traditional methods or impossible-to-manufacture conventionally.

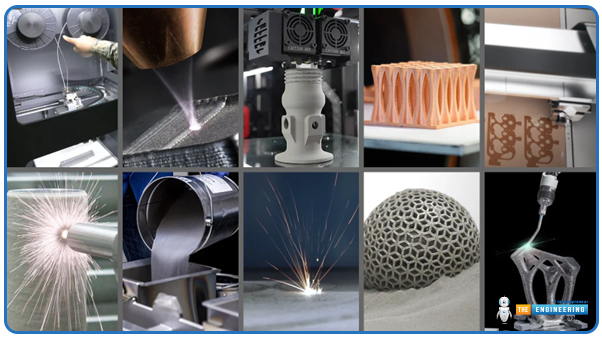

Several technologies exist within metal 3D printing. The popular methods include Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These methods melt metal powders with lasers or electron beams. Other techniques, Binder Jetting and Metal Extrusion were based on the combination of metal powders or filaments with binders to construct the component followed by baking in furnaces.

Key industries utilizing metal 3D printing involve aerospace, automotive, health care, and manufacturing. They enable the lightening of their products with lower waste, faster production, improved performance, and customized components. It is especially useful in developing complex aerospace parts, medical implants, and automobile prototypes. Advanced technology continues to bring innovative cost-effective solutions using metal 3D printing and its alternatives against traditional manufacturing techniques.

In this article, you will learn the complete working metal 3D printing. Let’s start.

1. Designing the 3D Model:

Metal 3D printing starts from designing the object that shall be printed. Many software packages use computer-aided design in developing such models, mostly in producing a very intricate model of any parts, structure, or part of anything in 3D. A highly critical design in 3D metal printing determines the kind of finishing on the part after it's done printing since this will depict its material characteristics and geometry.

After the completion, the 3D model can be exported in one of these digital file formats: STL or AMF (Additive Manufacturing File). The STL or AMF file formats will break the 3D model into extremely thin horizontal layers, essentially describing how the 3D printer should create the part, layer by layer. The resolution of the model is defined during this stage. It determines how precisely the final part will be. They also include lattice structures, channels, and moving parts in a model, things that cannot be possible or are nearly impossible to build with traditional subtractive manufacturing.

2. Choice of Suitable Metallurgical Materials:

Metal 3D printing has an extensive range of metallurgical materials, each of which possesses properties desirable for particular applications. The basic choice criteria typically rely on what mechanical properties of the part are needed, the environmental conditions under which the part will be operated, and the performance that is desired.

Yet some of the most widely used metals in metal 3D printing are:

Titanium Alloys:

Titanium and its alloys including the Ti-6Al-4V grade have a hardness, strength-to-weight ratio, corrosion resistance, and biocompatibility that make it suitable for most industries. In aerospace industrial applications and automotive, and generally, where light-weight and high strength is essential as in medical applications as in implants and prosthetic uses, titanium alloys are ideal.

Stainless Steel:

Stainless steel is a multi-purpose material having acceptable mechanical characteristics and resistance to corrosion. It is applied in many fields especially in industries manufacturing industries also in the making of medical equipment. Among the alternatives, the two typical alloys that are used in 3D printing are stainless steel 316L and 17-4PH.

Aluminum Alloys:

Aluminum has a relatively high strength-to-weight ratio, and good thermal conductivity and will therefore undergo all automotive and aerospace industries. Some of them include; AlSi10Mg, which is popular in the creation of light duty high strength components through 3D printing.

Inconel:

Inconel is an austenitic superalloy that has been used in reinforced operating situations such as in jet engines or gas turbines. It has kept away from sudden temperatures and corrosion for it to fit in the aerospace and energy markets.

Cobalt-Chrome Alloys:

The alloys are primarily used in the medical field to create implants and other dental-related parts. Cobalt-chromium gives strength, exhibits high wear resistance, and is biocompatible.

Copper and Nickel Alloys:

These are used in situations that necessitate maximum thermal conductivity like heat exchangers and critical corrosion resistance settings.

All the above types possess their benefits along with compromises of mechanical properties, cost, printability, and post-processing requirements. One of the significant strides toward optimal performance is the proper choice of the application-specific material.

3. Layer by Layer Printing:

Additive manufacturing forms the crux of metallic 3D printing, meaning depositing or creating material upon itself layer-wise, thus gradually constructing a full part. Differences abound in methodologies taken to deliver that layerwise building process from a variety of available technologies and those are now mentioned below-

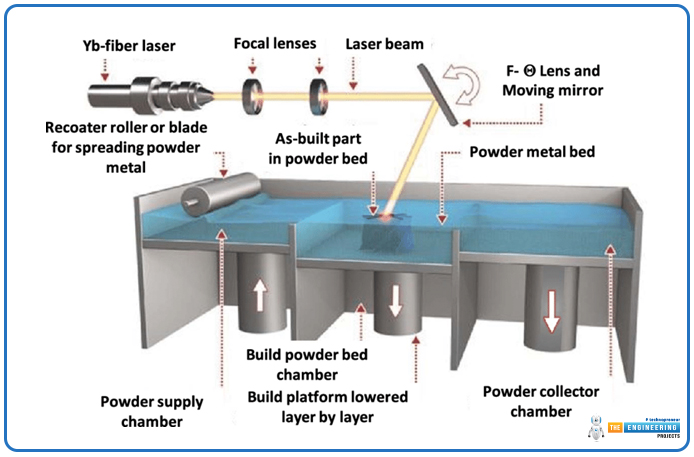

Powder Bed Fusion:

Powder Bed Fusion forms part of a popular and applied methodology for making a metal product by 3D printing technology. In PBF, a thin layer of metal powder is spread across a build platform. A high-powered energy source, including lasers or electron beams, is used to selectively melt or sinter the powder. The energy source scans across the powder bed, following the contours of the part's first layer, melting the powder in precise areas. This first layer is completed, and the platform will be moved downwards to a specific length while another metal powder layer is spread upon it, so the layer on top will get repeated from above until all the parts.

Here are some versions of Powder Bed Fusion:

Selective Laser Melting (SLM): In this process, the high-powered laser melts metal powder completely. Thus, it gives parts that exhibit excellent mechanical properties. The main application areas include aerospace, automotive, and medical applications in making complex high-performance parts.

DMLS: Similar to SLM, it uses a laser but works by sintering the metal powder, and partially melting it to bond the particles. DMLS is particularly useful in intricate designs and small-scale production.

EBM, or Electron Beam Melting: This, melts metal powders using an electron beam instead of a laser beam and occurs in a vacuum that helps to avoid oxidation. This is the most desirable application for this process in aerospace or medical implants, as some reactive metals fall into the category of titanium alloys and nickel ones.

The application areas for the PBF technology include high accuracy and resolution, such as those related to complex geometry and high-strength applications.

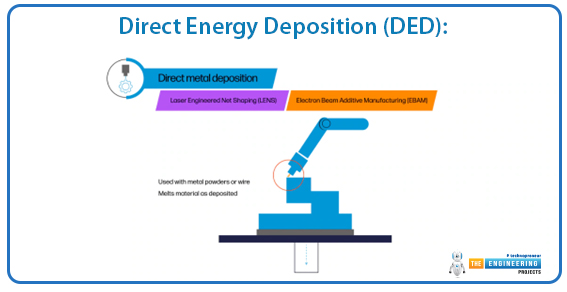

Direct Energy Deposition (DED):

Direct Energy Deposition (DED) is another type of 3D printing technology in which metals are printed as parts or additive material to the component. In this process, a nozzle feeds a metal powder or wire, and the energy source heats it in a laser, electron beam, or plasma arc. This hot material then hardens as it cools upon coming into contact with a substrate or part and repeats the layer-building process.

DED is significantly advantageous for huge applications such as repairing worn-out parts or deposition of material on an existing part. This technique is ideal for aerospace, defense, and heavy machinery industries.

Though DED has a higher speed of production as compared to PBF, it cannot be used in terms of resolution and surface finish. The output produced by the DED technology is usually sent for some post-processing to get an excellent finish.

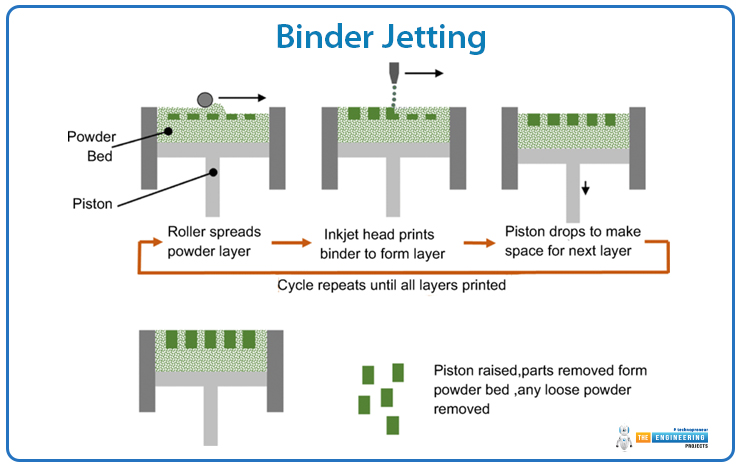

Binder Jetting:

Binder Jetting is an indirect process of metal 3D printing where a binder material is deposited on metal powder particles to form a part. Unlike PBF, the process of binder jetting does not melt the powder. Instead, it acts as a glue to attach the powder particles to make a "green part." Following this, a post-processing furnace burns out the binder and sinks the metal powder particles in such a manner that it ultimately forms a solid part.

Binder Jetting is faster and more affordable than PBF, but it produces parts with lower mechanical strength; therefore, most practical uses are for prototypes or low-run production of parts.

Metal Extrusion (Bound Metal Deposition):

In Bound Metal Deposition (BMD), which is also referred to as metal extrusion, a metal powder-polymer binder-based filament is used to create a hot, extruded product from which material is laid down layer after layer in creating the part. This product, after printing is completed, has to undergo debonding in which the polymer binder is removed and the metal part gets submitted for sintering in a furnace, to remove the binder residue and then densify the part.

This method is generally applied for prototype creation and low-volume production parts. Metal extrusion is a cost-effective and easy-to-handle process that can be implemented by desktop 3D printers in small manufacturing environments.

4. Post-Processing:

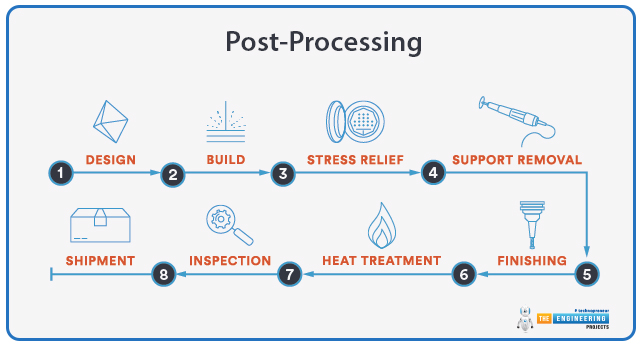

After printing, the metal part would often undergo post-processing steps to achieve increased mechanical properties, surface finish, and accuracy.

The primary post-processing steps are the following:

Sintering: the binder jetting and metal extrusion process requires sintering of the printed part where a furnace heats the part to join together the metal particles at increased density in the part.

Heat Treatment: This method makes use of annealing, hardening, and stress-relieving heat treatments to make the mechanical properties, hardness, toughness, and fatigue strength of the part better.

Machining: After printing and sintering, there are still several additional machining processes involved in completing milling, grinding, or turning, depending on achieving the desired dimension and finish surface.

Support Removal: The majority of metal 3D printing technologies, especially PBF and DED, require support structures for overhanging or complex geometries to print over the printed feature. These have to be removed post-print, either manually or utilizing automation.

5. Quality Control and Testing:

This quality control and testing ensure that the metal 3D printed parts meet the required specifications and perform their intended functions. The part then undergoes various tests after being printed and post-processed to prove its integrity and functionality.

Dimensional inspection:

The measured and tolerable dimensions of the printed part will be verified against the precision of measuring tools, like micrometers, calipers, or even 3D scanners. Any difference made in the measurement will be adjusted with additional machining or adjustments for the part until it meets its design specifications.

Mechanical Testing:

To gauge the ability of the part to behave under load, tensile strength, hardness, fatigue, and elongation are made. These give assurance that a part has acquired the right kind of mechanical property for its intended function, including survivability under given operational conditions.

Non-Destructive Testing:

In NDT, X-rays, ultrasonic testing, and CT scans are used to scan the inner structure of the part for porosity or other flaws. The above tests do not damage the part and show any hidden flaw within the inner part, so it is always reliable and durable.

6. Applications of Metal 3D Printing:

This process has become widely used, as it may now be feasible to produce such extremely complex and customized parts with reasonable mechanical properties. Major applications of metal 3D printing are:

Aerospace:

Metal 3D printing is also applied in aerospace to design lightweight, high-strength parts for items including turbine blades, engine components, and structural elements. Rather it is a very important process in aerospace as it will enable complex geometries that have reduced part weight so far.

Medical:

Metal 3D printing is implemented in the medical sector to have custom implants, prosthetics, and surgical instruments. This happens because titanium alloys are biocompatible and quite strong.

Automotive:

In the automotive manufacturing area, metal 3D printing is applied in the manufacture of lightweight parts, a metamorphosis that encompasses efficient fuel consumption and minimal emission. It is also applied in the production of prototyping of a small number of highly specialized parts.

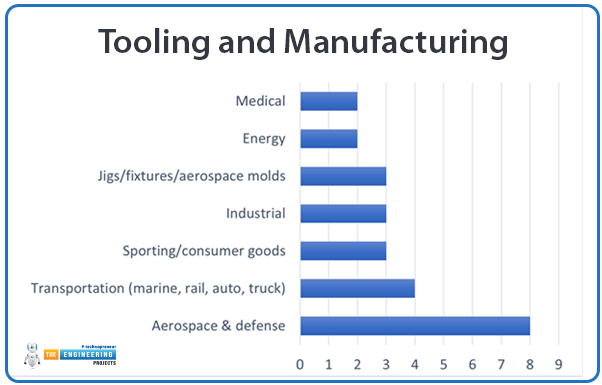

Tooling and Manufacturing:

end-use parts in tooling and jigs that would be employed in production are made from metal 3D printing. This is most often used for putting together models in the production line as well as manufacturing special parts in every field.

Conclusion:

It is revolutionizing manufacturing with the possibility of developing complex, customizable metal components. There is a design of a 3D model on CAD software before the selection of an appropriate material. Deposition techniques used for layer-by-layer deposition are Powder Bed Fusion, Direct Energy Deposition, Binder Jetting, or Metal Extrusion. After getting printed, the parts have to go through some post-processing steps to enhance both their mechanical properties and surface finishes. The final product will be absolutely by the specifications and strict quality control with testing. The applications of metal 3D printing range incredibly wide from the aerospace to automotive and health industries, such as design flexibility, lightweight components, and fast prototyping. We expect even more efficient and precise printing methods and new materials and applications as technology advances. This will further stretch the potential for additive manufacturing, continue transforming industries, and create new avenues in product design and production.

3D Printing

3D Printing xeohacker

xeohacker 0 Comments

0 Comments