Why does a flag wave in the wind, or a tall building sway on a gusty day? The answer lies in a fascinating field of engineering. At CFDLAND, we help solve these complex challenges through our hands-on Fluid-Structure Interaction (FSI) tutorials .

Fluid-Structure Interaction, or FSI, is the study of how fluids (like air and water) and solid structures affect each other. Think of it as a two-way conversation. The fluid pushes or pulls on the object, causing it to bend, move, or vibrate. In return, that movement changes how the fluid flows around the object.

This powerful interaction is happening everywhere, from the wind pushing on a turbine blade to generate electricity, to blood flowing through a flexible artery. Understanding this is critical for designing safer bridges, more efficient pumps, and life-saving medical devices. This guide will explore some amazing real-world examples of FSI analysis and explain the basic concepts that make these simulations possible.

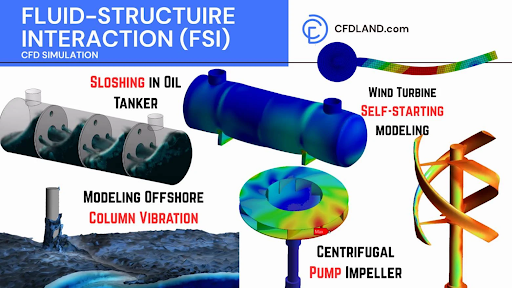

Figure 1: Examples of FSI simulation, including sloshing in tankers, offshore column vibration, and wind turbine modeling.

Real-World FSI in Action

Fluid-Structure Interaction is not just a theory; it solves critical problems across many industries. By simulating how fluids and solids work together, engineers can create safer, stronger, and more efficient designs. Let’s look at some powerful examples from the CFDLAND tutorials.

Powering Our World: Energy and Marine Engineering

In the energy sector, FSI analysis is essential. Consider a giant wind turbine. The wind pushes on the long blades, causing them to bend and flex. This movement changes the airflow, which in turn affects the power generated. A wind turbine FSI simulation helps engineers design blades that are both strong and efficient.

In marine engineering, the ocean is a powerful force. Simulating an offshore oil platform shows how massive waves push against the support columns, causing them to vibrate. Engineers use FSI simulation to ensure these structures can survive the toughest sea conditions. Another key challenge is liquid sloshing. A Sloshing FSI analysis shows the huge forces created by oil moving inside a tanker ship, helping to design safer vessels that won’t be damaged by the shifting cargo.

Figure 2: A sloshing FSI simulation showing the pressure and motion of liquid inside a moving tanker.

Improving Everyday Machines

Many machines we rely on have parts that move within a fluid. A centrifugal pump, for example, uses a spinning part called an impeller to move water. The water pushes on the impeller blades, which can cause them to slightly deform. This is a perfect example of fluid-solid interaction. Simulating this helps engineers build more durable and effective pumps that last longer.

Designing for Life: Biomedical Breakthroughs

FSI in biomedical engineering helps us understand the human body and create life-saving devices. For instance, simulating blood flow through an artery shows how blood pressure pushes on the flexible artery walls, causing them to expand and contract. This helps doctors understand diseases and design better stents. An even more detailed example is a human eye FSI simulation, which can model how fluid inside the eye interacts with delicate parts like the iris. This research is crucial for developing new treatments for eye conditions.

How It Works: The Basics of FSI Simulation

So, how do engineers simulate these complex interactions? The key is to choose the right approach for the problem. There are two main methods for any FSI simulation, and powerful software like ANSYS helps bring them to life.

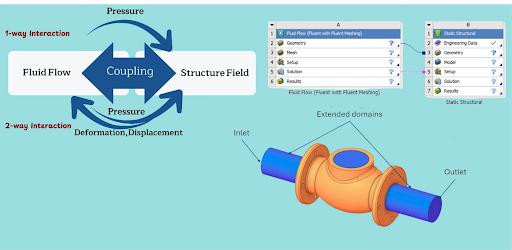

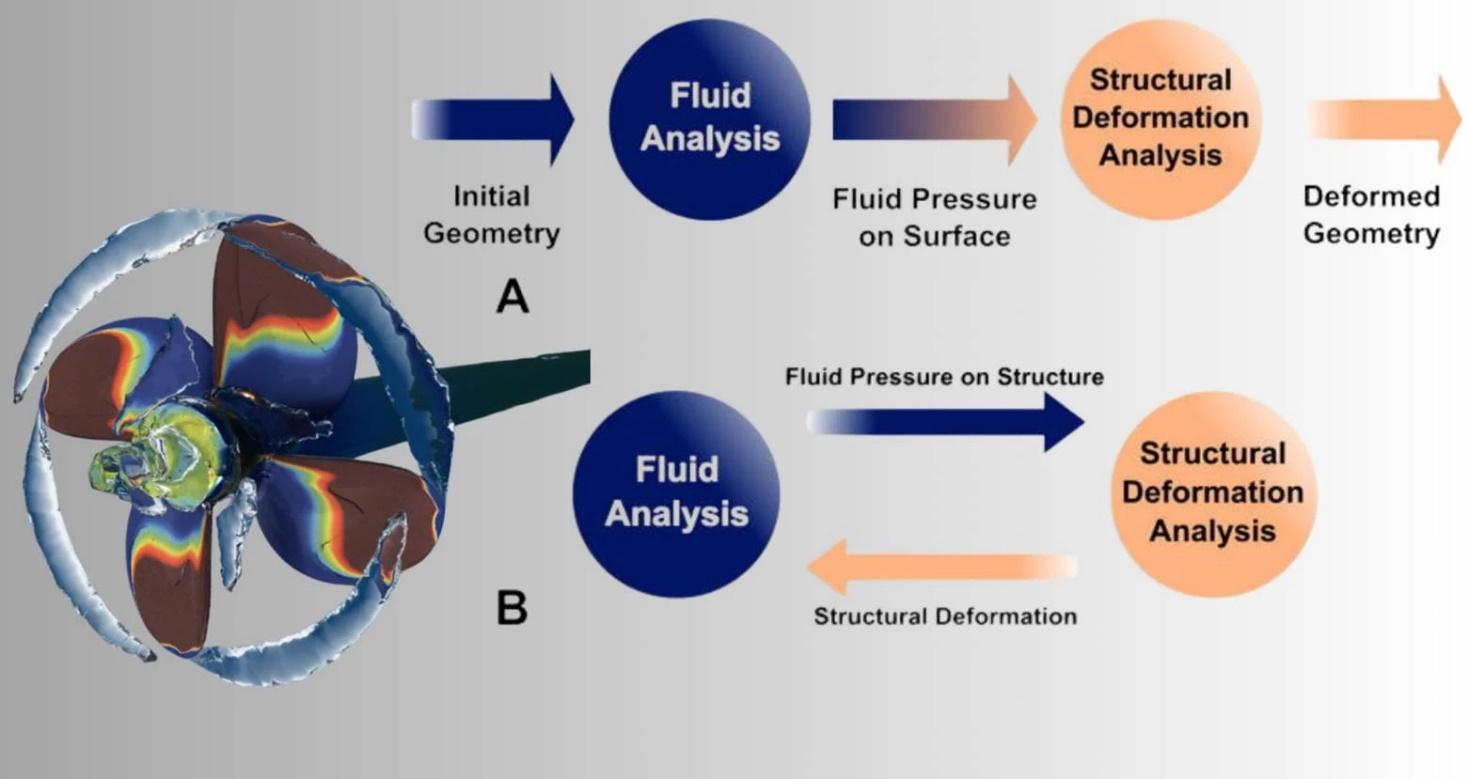

One-Way FSI vs. Two-Way FSI

The first choice is deciding how the fluid and solid will “talk” to each other.

One-Way FSI: This is the simpler approach. The fluid pushes on the solid, and we calculate the effect (like stress or bending). However, we assume the solid’s movement is too small to change how the fluid flows. One-way FSI is perfect for problems like calculating the wind force on a strong, stiff building. It’s faster and requires less computing power.

Two-Way FSI: This is the complete, interactive approach. The fluid affects the solid, and the solid’s resulting movement affects the fluid back. This creates a continuous feedback loop, just like a flag waving in the wind. Two-way FSI is more accurate and is essential for complex problems where movement is large, such as a flexible heart valve opening and closing.

Figure 3: simple diagram showing the difference between One-Way FSI and Two-Way FSI. One-way is a single action, while two-way is a continuous feedback loop.

Making it Happen with FSI in ANSYS

To perform these simulations, engineers rely on advanced software. The FSI ANSYS environment is an industry-leading tool for this. It works by using a platform called ANSYS Workbench to connect different specialized solvers.

For an ANSYS Fluent FSI simulation, the process looks like this:

ANSYS Fluent calculates the fluid flow and the forces it creates.

ANSYS Mechanical calculates how the solid structure deforms or moves under those forces.

A special tool called System Coupling acts as a manager between them. It handles the fluid-solid coupling, passing data back and forth in each step of a two-way FSI to ensure the results are accurate and realistic. This integrated system makes it possible to solve even the most challenging Fluid-Solid Interaction problems.

Figure 4: The FSI ANSYS setup in Workbench. Tools like ANSYS Fluent and Mechanical are linked together using System Coupling to perform the simulation.

Conclusion

Fluid-Structure Interaction is a powerful tool that is changing modern engineering. By understanding the two-way conversation between fluids and solids, we can design safer aircraft, build more robust offshore structures, and create life-saving medical devices. Whether using a simple one-way FSI for a rigid structure or a complex two-way FSI for a flexible one, these simulations give us an incredible view of how products will behave in the real world.

Applying these simulations correctly is the key to getting reliable results. The expert team at CFDLAND specializes in solving these challenging Fluid-Solid Interaction problems and helping engineers master these essential skills.

Tutorials

Tutorials xeohacker

xeohacker 0 Comments

0 Comments