Step into the world of precision engineering—where custom CNC machined parts transform raw materials into the sinews and bones of your next big project. Like a tailor crafting a bespoke suit, CNC machining offers an unparalleled fit for your specific requirements.

The prospect of holding your idea in your hands, not just on paper, is the realm where imagination meets implementation. But what options lie at your fingertips? Let's explore the paths to turning those digital blueprints into tangible assets.

Materializing Visions: The Alloy of Choice

Before the whirring of machines begins, your quest starts with choosing the right material—a decision as critical as selecting the foundation for a skyscraper. Each material whispers its own strengths and secrets, waiting to align with your project's demands.

Aluminum

For starters, aluminum stands out as a front-runner in popularity due to its lightweight yet robust nature —an ally for components in aerospace or portable devices. Imagine the sleek body of a drone or the frame of a prototype sports car; they likely share an aluminum heartbeat.

Stainless Steel

Stainless steel steps forward for projects where endurance and rust resistance are paramount. Think of medical devices that can withstand repetitive sterilization or marine parts whispering secrets to ocean waves without fear of corrosion.

Image Source: Pixabay

Titanium

Delving deeper into specialties, titanium emerges when the strength-to-weight ratio is not just a preference but a necessity—ideal for high-performance sectors such as motorsports or prosthetics.

Brass

Brass occupies a niche where electrical conductivity must dance elegantly with malleability—perhaps in custom electronic connectors or intricate musical instruments.

Each material imparts its essence to your project, shaping not just function but also future possibilities. Which one will be the bedrock for your engineering aspirations?

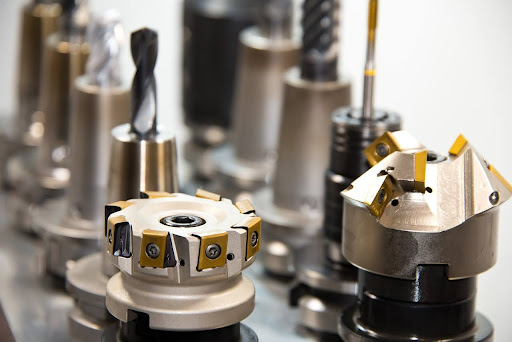

Carving Precision: The Toolpath Less Traveled

The next step on our journey approaches like the unveiling of a trail in dense fog—selecting the appropriate CNC machining process that will breathe life into your vision. Each method manifests its prowess through sparks and shavings, ready to tackle complexity with finesse.

Better yet, since there are a variety of machines from Revelation Machinery on offer, with second-hand units representing better value than new equivalents, you can pick one of the following without breaking the bank or limiting yourself in terms of functionality and features.

Milling

3-axis milling is like the steadfast hiker; it's reliable and perfect for parts with fairly simple geometries. If your project involves creating a prototype bracket or a basic gear, this could be your marching tune. But when contours call for more intricate choreography, 5-axis milling pirouettes onto the stage. It invites you to envision turbine blades sculpted with aerodynamic grace or an ergonomic joystick that fits into hands as naturally as pebbles on a beach.

Image Source: Pixabay

Turning

Turning—the spinning dance between material and tool—offers cylindrical mastery manifested in objects rotating around their own axis. This is where items such as shafts for motors or precision rollers for conveyor systems are born from rotation's embrace.

EDM Options

But what if your piece hides complex internal features, akin to secret passages within a castle? Enter EDM—Electrical Discharge Machining —a process where electrical sparks rather than physical cutting tools unlock hidden gems. Ideal perhaps for making intricate molds used in injection molding machines that will churn out hundreds of thousands of perfectly replicated plastic knights.

As if wielding a magic wand, wire EDM carves with finesse where traditional tools cannot tread, slicing through hardened steel as easily as a hot knife through butter. Consider the labyrinthine path of a lightweight gear or the delicate framework of an instrument sensor—wire EDM is your guide through these intricate landscapes.

Then there’s the level-headed sibling in this family, plunge/sinker EDM—an ace up your sleeve when three-dimensional complexity calls. It's perfect for forming punch and die combinations used in manufacturing presses that shape sheet metal into automotive body panels or appliance housings with clockwork precision.

Decision Time

The truth nestled within these processes promises tailored solutions to even the most enigmatic engineering puzzles. Your custom CNC machined part will emerge from its fiery birthright not just created, but crafted with intent. In this emporium of efficiency and accuracy, which CNC sorcery will you enlist to transform your concept into creation?

Finishing Touches: The Symphony of Surfaces

Now that the form has been forged, it's time for the maestro—finishing—to step up and conduct a symphony of surfaces. This is where rough edges soften and exteriors gleam, ready for their grand debut.

Anodizing

Anodizing tiptoes onto stage left, offering its protective embrace to aluminum parts. It’s a finish that doesn't just add a splash of color but also bolsters resistance to wear and corrosion. Picture an aerospace fitting beaming with radiant blue or a fire engine red bicycle frame standing resilient against scratches and weathering.

Powder Coating

Powder coating strides in with its own brand of rugged beauty—a finish that cloaks objects in a uniform, durable skin impervious to the elements. Outdoor machinery basks in its shielding layer, flaunting colors that withstand sun, rain, and the passage of seasons.

Image Source: Pixabay

Precision Grinding

For components that need to glide together as smoothly as ballroom dancers, you’ll want to consider precision grinding. Imagine automotive pistons or mechanical bearing races—their surfaces milled down to microscopic levels for tolerances tighter than a drum skin.

Bead Blasting

Perhaps your masterpiece calls for an understated elegance; then bead blasting might brush across the scene. It leaves behind a matte texture that diffuses light and speaks to sophistication. Its application speaks volumes on products where glare is the enemy and understated aesthetics are paramount—like the dashboard of a luxury car or the casing of high-end audio equipment, where touch and sight merge into user experience.

Electroplating

Let's not forget electroplating—the alchemist's choice that transmutes base metals into gold, well, in appearance at least. Here we witness components such as plumbing fixtures or electronic connectors being vested in extra layers for improved conductivity and aesthetic appeal, shimmering with purpose and resilience.

Passivation

If subtlety is your aim, then passivation is your unassuming guardian. Stainless steel medical instruments or food processing parts bask in this chemical bath, emerging more stoic against rust and degradation—an invisible shield for an unspoken duty.

Etching

As the encore approaches with laser etching taking center stage, customization reaches another level. It allows you to adorn surfaces with serial numbers, logos, or intricate patterns—turning each part into a storyteller of its own journey from concept to finality.

The Last Word

All this info should set you up to make smart decisions ahead of creating custom CNC machined parts for any engineering project you have in the pipeline. And it’s worth restating that as well as choosing carefully, buying used machinery is another way to get great results that will make your budget manageable.