Hey readers! Welcome to the penetrative guide to PCB manufacturing. Hopefully, you are doing well and looking for something great. The solder mask is the most vital component in manufacturing a printed circuit board (PCB), which guarantees reliability and ensures that everything functions smoothly.

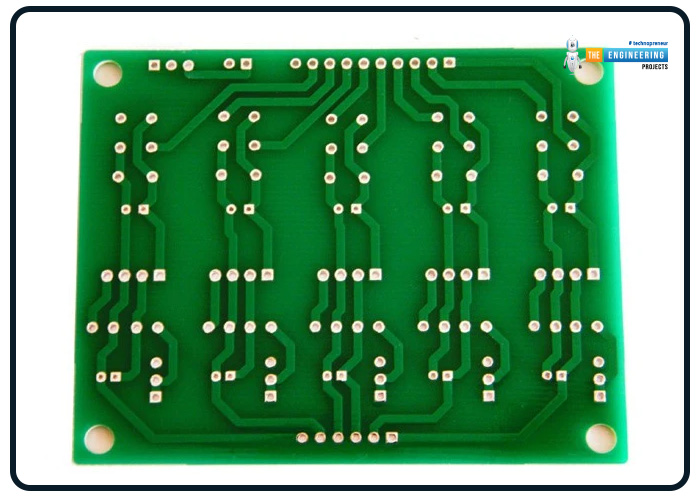

These printed circuit boards serve as the backbone for almost all modern electronics, right from the simple household consumer products like a smartphone and a laptop to diverse applications such as industrial machinery and space equipment. A PCB provides physical and electrical connections and support for the components of electronics. The most crucial area for protection is the solder mask because of its great contribution to the copper behavior of an entire circuit regarding oxidation, dirt, and solder bridging problems during fabrication.

There are different classes of solder masks, but in dense and high-precision applications, the most commonly used solder mask has been LPI or Liquid Photo Imageable. LPI solder mask is an ultraviolet (UV) light-sensitive liquid film coating applied to the PCB surface and cured partially with UV light using either a photomask or laser direct imaging system. The curing dries the liquid, and depending on the subsequent process, can protect circuit traces with extremely tight accuracy of registration, making LPI solder mask very capable for complex electronic packaging and fine pitch electronic design.

LPI solder masks possess numerous advantages, including excellent resolution, superior adhesion, thermal and chemical stability, and fine-pitch parts compatibility. Their accurate deposition and endurance-based operation qualify them as the commercial and state-of-the-art PCB manufacturing standard. With technological advancements, LPI solder masks will remain critical in manufacturing high-performance, dependable circuit boards.

In this article, you will find the features, composition, and application process of LPI Soldeer Mask.

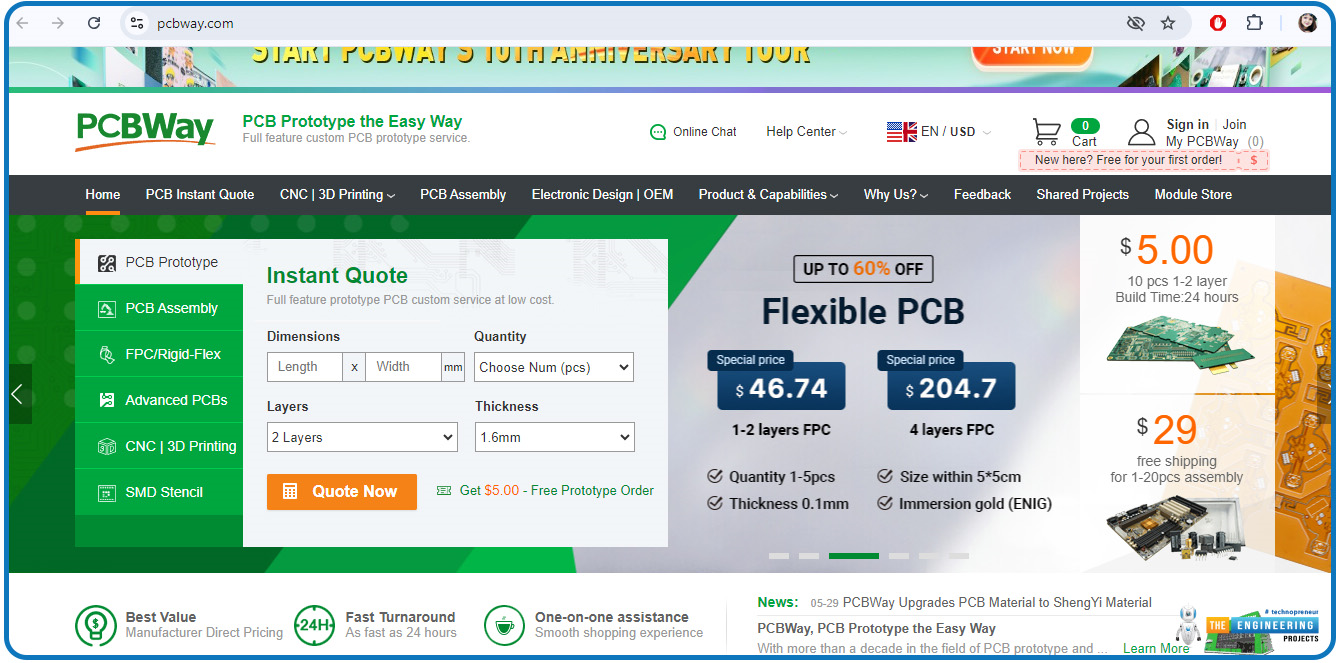

Where to Order PCBs?

If you want to use the absolute best and trusted option for your quality Printed Circuit Boards (PCBs), look no further than PCBWay Fabrication House. PCBWay is known and trusted by engineers, makers, and electronics companies all over the globe. With years of experience in the industry, PCBWay can deliver engineered quality PCBs for personal prototypes to build products that involve complex industrial applications, to service providers that help and facilitate other businesses.

What is great about PCBWay is the number of variables you can apply to your design. You can select multiple solder mask colors, multiple surface finishes applied over copper, board thicknesses, and flex, rigid-flex, or multilayer designs. PCBWay utilizes highly automated facilities with advanced quality control procedures to ensure the end product is always accurate and precise, even for fine-pitch, high-density boards. For its services, check its page:

It is simple to order from PCBWay. You can easily submit Gerber files using their intuitive online platform, get quotes instantly, and track orders in real time. PCBWay also has reasonable prices and a very responsive English-speaking support team, making PCBWay your partner for your PCB fabrication needs, consistently delivering speed, reliability, and value in every order.

What is LPI Solder Mask?

Liquid Photo Imageable (LPI) solder mask is a type of UV-sensitive liquid coating that goes onto the surface of the PCB. It is placed onto the surface and then hardened in a selective manner using ultraviolet (UV) light either through a patterned photomask or a direct imaging system. The selective hardening of the mask allows the mask to be developed precisely by leaving voids only in the places desired for soldering, such as pads from components and vias.

LPI solder masks are more beneficial in high-density interconnect (HDI) boards, BGA (Ball Grid Array) layouts, and fine-pitch components, among others. In high-density work, there is very little space for soldering bridges, and sometimes only the smallest bridge can have implications that will fail the entire circuit.

Composition of LPI Solder Mask:

Liquid Photo Imageable (LPI) solder mask is a specialized material made up of specific chemical components that work in unison in a series of steps, all contributing to the performance, longevity, and photoimageable qualities. Knowing this composition helps affirm why it is one of the preferred materials in current, modern high-density PCB manufacturing.

1. Epoxy or Acrylic Resin Systems:

At its core, the resin system in LPI solder masks, which is predominantly based upon epoxy or acrylic polymers, is vital for the mechanical strength, adhesion, and electrical insulation to perform repeatably on PCBs. Epoxy systems are the preferred systems because of the thermal properties and chemical resistance, which allows for use with lead-free soldering and extreme environments. Acrylic rods can be an option for applications where flexibility is important.

2. Photoinitiators:

Photoinitiators are the UV-sensitive chemicals that help the mask harden upon UV light exposure. They are critical for the polymerization of the resin during the imaging process of the solder mask, as they allow for the pattern to develop properly. The effectiveness of the photoinitiators will define the exposure time and resolution that will be essential for tight-pitch PCBs.

3. Pigments:

Pigments are what provide the solder mask with its color (green is traditional, but also red, blue, black, white, or yellow). Pigments also have a functional purpose by blocking unwanted UV light and thus help to prevent overexposure of the area, which is not intended to be developed. Pigments also help to increase visual contrast to assist with visual inspection.

4. Solvents and Additives:

Solvents are added to control the viscosity of the liquid for controlled application of the solder mask via curtain or spray coating. The solvents evaporate during the tack-dry phase. Additives are included to improve specific properties such as adhesion, leveling of surface, UV resistance, and allow for solder mask to be tailored for different production and environmental conditions.

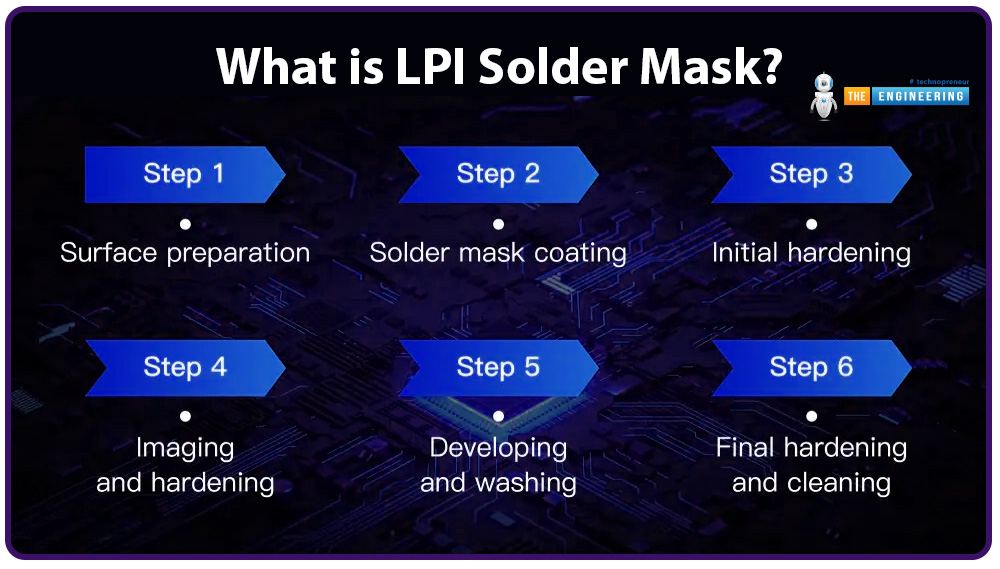

LPI Solder Mask Application Process:

The application of Liquid Photo Imageable (LPI) solder mask to a printed circuit board is a multi-step process that requires care, cleanliness, and a proper application tool. Every step in the process is imperative to the performance of the mask under electrical and thermal stress during assembly and operation.

Step 1: PCB Cleaning:

Before application, a PCB must be cleaned thoroughly. Cleaning is done to remove any oxidation, dust, grease, or residues that would negatively affect the adhesion of the solder mask to the PCB. Common methods of cleaning include chemical cleaning with alkaline or acidic solutions and plasma treatment for deeper surface activation. A clean surface will not only promote better bonding between the mask and the copper or other substrate but will also reduce the possibility of delamination or peeling during later assembly and operation.

Step 2: Solder Mask Application

Once clean, the liquid form of LPI solder mask is then applied to the surface of the printed circuit board (PCB). The application is done in the following three ways:

Curtain Coating: The method most widely employed in high-volume production when the board is processed through a curtain of liquid solder mask.

Spray Coating: The method of choice when the boards cannot be easily coated using curtain coating due to the complexity of geometry or for small volume runs. Spray coating is a method that is easy to apply to any shape or size. Typical use is in production volumes for even and uniform coating onto an irregular surface.

Screen Printing: Now a less prevalent method, but is also performed with indications in unique design or prototype applications.

The aim is to have a uniform, bubble-free coating covering the entire surface of the PCB.

Step 3: Tack Drying (Pre-curing)

After application, the tack drying step takes place in a convection-type oven or a heat source where the board is heated to a specified temperature to almost harden the solder mask so it can hold its shape while being exposed to UV light in the next step without it flowing or smudging. The board will be flexible enough for imaging, but hard enough to avoid distortion of the mask during imaging.

Step 4: UV Exposure

The tack dried PCB is now exposed to near-UV light. This is done conventionally with a photomask that has specific openings or by utilizing a Laser Direct Imaging (LDI) method that offers a higher level of accuracy. The exposure of the solder mask initiates polymerization at the openings, hardening the solder mask in those areas only.

Step 5: Developing

During this stage, the board is exposed to a basic solution (usually sodium carbonate) to remove the exposed, soft mask material, and all that's left behind are the copper pads or vias to solder.

Step 6: Final Cure

Lastly, the PCB will go through thermal baking or final UV curing to completely cure the chip location solder mask. This will complete the process and ensure the solder mask is completely durable, chemically resistant, thermally stable, and sturdy enough to be soldered and perform reliably in real life.

Advantages of LPI Solder Mask:

Liquid Photo Imageable (LPI) solder mask provides various benefits, making it the standard for cutting-edge printed circuit board production today. Its chemical makeup, accurate application method, and suitability for leading-edge technologies enable it to satisfy the strict requirements of today's high-density, high-performance electronics.

1. High Resolution for Fine-Pitch Designs:

The prime benefits of LPI solder masks made high-resolution imaging possible. Their applications are extremely effective on PCB designs that contain very closely spaced traces or fine-pitch components. As the size of electronics shrinks and they become more complex, there has been an increasingly higher demand for precision in all areas of design. LPI solder masks provide the highest possible accuracy in alignment and definition of openings. This means that with LPI solder masks, there will be no overlap of solder mask onto pads or vias. This level of precision leads to far lower chances of solder bridging or unwanted shorts during assembly.

2. Durable in Tough Environments:

LPI solder masks are legendary for their well-documented durability after full curing. LPI solder masks displayed extremely excellent chemical resistance, moisture, and abrasion in addition to being high-temperature resistant. They are commendably suited for applications wherein these PCBs will probably be subjected to harsh environmental conditions. Such can include PCB applications for automotive and aeronautical electronics, as well as industrial controls. LPI solder masks are very durable and withstand thermal cycles as dictated by lead-free soldering processes. This compatibility adds to LPI solder masks' strength concerning modern manufacturing processes.

3. Excellent Adhesion and Long-Term Performance:

First, the adhesion of the LPI solder mask to copper traces, as well as PCB substrate material, is better than other solder mask processes. This kind of adhesion proves extremely effective as long as the PCB is not mechanically stressed or thermally cycled, so that we can be sure that the mask will remain in place without delamination and cracking with time as a result of the nature of this adhesion and design reliability, as well as the fabrication of the solder mask.

4. Compatibility with modern manufacturing processes:

Relatively smooth and uniform surface characteristics will enable high-performance LPI solder masks under any modern manufacturing inspection capability, such as automated optical inspection (AOI). With the defined LPI mask, the clarity of pad and solder connections during inspection is greatly improved, providing a lower probability of missed defects because of bad signal quality. Also, a reliable LPI solder mask is compatible with surface mount technology, resulting in fast, high-volume, productive assembly processes for SMT technology.

5. Environmentally Friendly and Cost-Effective:

The process for using LPI solder mask produces less waste and is more resource-conservative compared to older types of solder mask.

The efficiencies of the LPI process and high-volume production allow assembly manufacturers to lower their costs instead of raising their prices on future jobs while maintaining high standards of quality in their assembly processes.

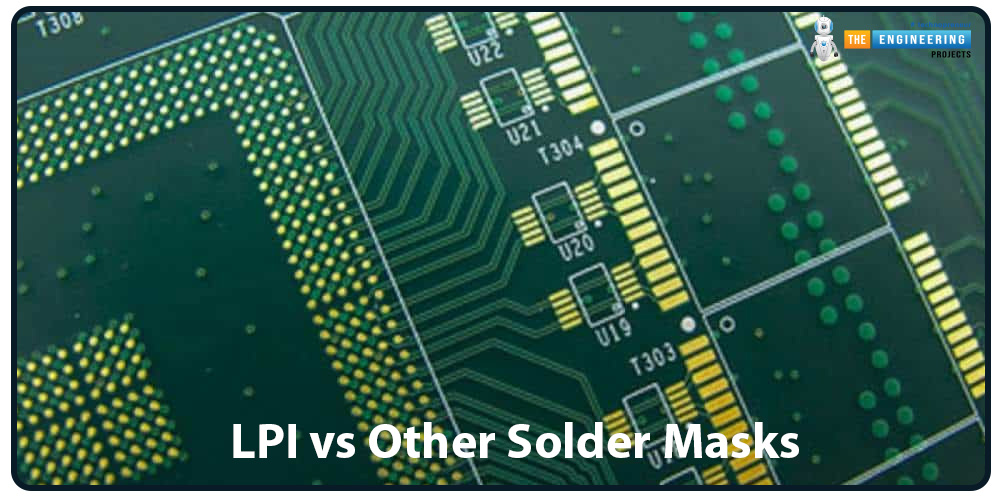

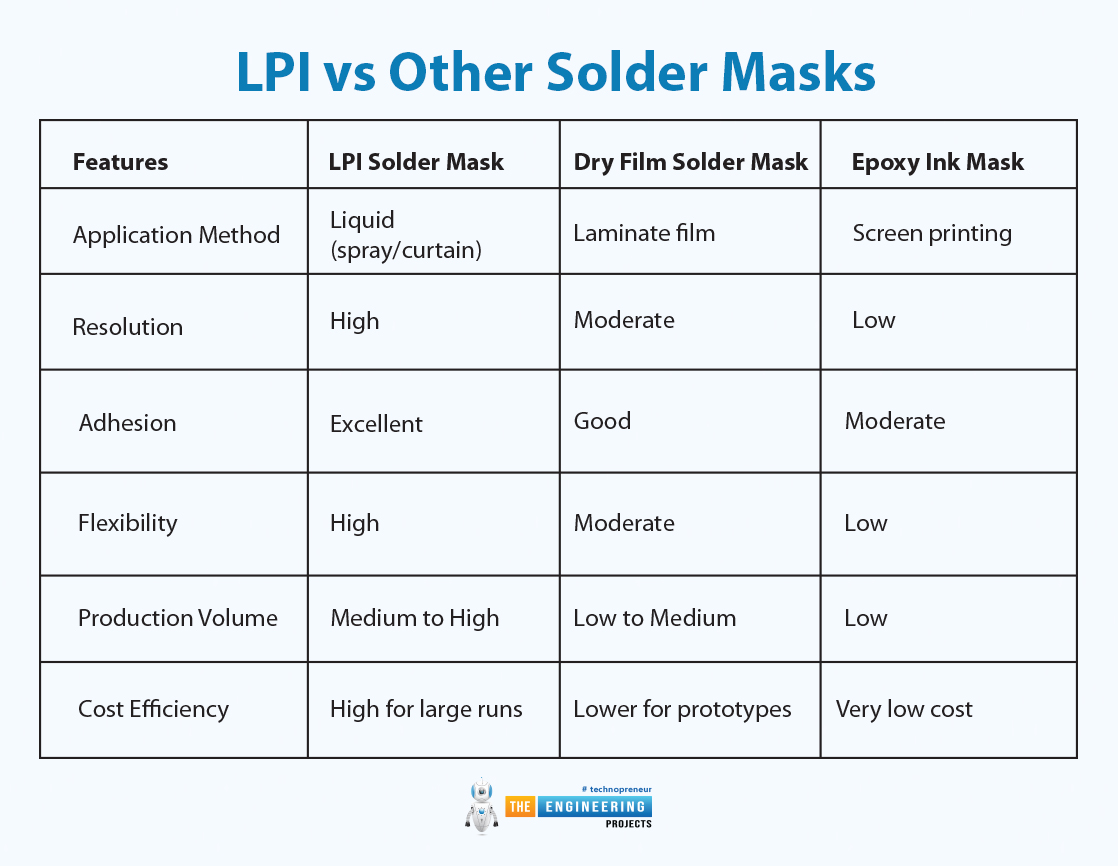

LPI vs Other Solder Masks:

Features |

LPI Solder Mask |

Dry Film Solder Mask |

Epoxy Ink Mask |

Application Method |

Liquid (spray/curtain) |

Laminate film |

Screen printing |

Resolution |

High |

Moderate |

Low |

Adhesion |

Excellent |

Good |

Moderate |

Flexibility |

High |

Moderate |

Low |

Production Volume |

Medium to High |

Low to Medium |

Low |

Cost Efficiency |

High for large runs |

Lower for prototypes |

Very low cost |

Conclusion:

The Liquid Photo Imageable (LPI) solder mask is a crucial component in today's PCB manufacturing, giving the proper accuracy, strength, and reliability for the electronic designs employed today. Its ability to facilitate fine-pitch components, withstand challenging environmental conditions, and offer durable adhesion contributes to the deployment of both high-density consumer electronics and mission-critical industrial systems.

Of course, LPI solder mask also brings some other advantages in addition to its functionality. The user benefits from improved process efficiency with environmentally friendly build processes. The effectiveness of LPI with fully automated processes such as surface mount technology (SMT) and automated optical inspection (AOI) adds to its appeal, resulting in process efficiencies and a guaranteed quality process providing reliability.

As devices become more complicated and smaller, obtaining accuracy levels and reliability will become paramount. If your application falls under the umbrella of next-gen IoT, automotive systems, or aerospace, you could not make a better choice than LPI solder mask to ensure your designs not only hold their value over time, but also offer a guarantee of performance in the real-world application.

Printed Circuit Boards

Printed Circuit Boards xeohacker

xeohacker 0 Comments

0 Comments