JLCPCB never take undue advantage of Non-A grade board

Global PCB raw material costs are rising, JLCPCB never takes undue advantage of Non-A grade board. Last year the whole PCB manufacturing industry faced raw material shortage issues. Many PCB companies sent internal letters to their customers stating that copper prices have risen by more than 50%, copper foil processing costs have risen by more than 20%, and demand continues to increase, resulting in a surge in copper foil prices. The current copper foil prices Compared with the third quarter of last year, it has increased by about 50%

Nanya company issued a notice about growing price, saying that the prices of CCL-related raw materials including LME copper, copper foil processing fees, epoxy resin, and fiberglass cloth continued to increase in price, coupled with tight supply and demand, in order to ease Due to cost pressure, it is planned to increase the price by about 15%-20% of the total transaction amount, which will take effect from April 1st this year."

This kind of shortage caused a battle for grabbing raw materials. But JLCPCB never takes undue advantage of the Non-A grade board. The raw material cost growth situation seems to slow down in June 2021. JLCPCB's single, double boards and small-volume board overseas prices have been lowered from June 5th, 2021 as long as the price of the core raw materials of the circuit board decreases. Cost increment for raw material is a daunting matter. The sheet material is the core and main raw material of PCB, accounting for about 6% of the cost. Using a piece of A-grade raw material and using a piece of non-A-grade material is a great temptation for PCB manufacturers to make profits. If you want to save the cost of raw materials, it is also the most costly raw material.

JLCPCB real grade A1 material

A1 grade base material

- Application for general automotive boards and household appliances PCBs.

- Applicable circuit: the hole diameter is greater than 0:25mm

A3 grade base material

- Application for: toy boards, ordinary CTI household appliances classes, and P4-LED light boards, requiring low voltage and low current

- Applicable circuit: plug-in hole diameter greater than 0:4mm

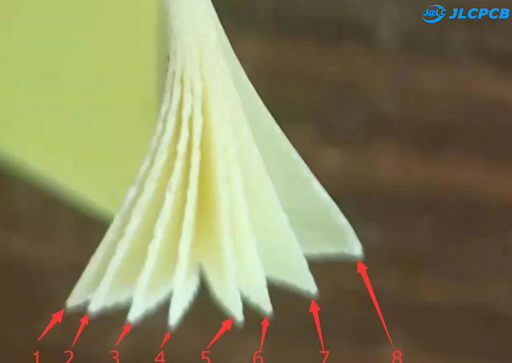

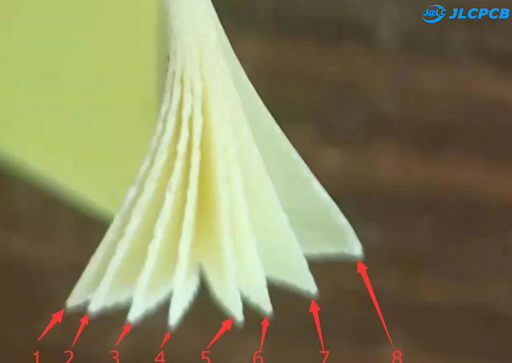

JLCPCB real grade A1 material

- 1.6mm sheet thickness

- 8 sheets of cloth

- flame retardant

- full copper (17.5um)

Other PCB company A3 grade material

- 6 sheets of cloth

- non-flame retardant

- copper thickness 12-15um

The price difference between the two is as high as $10/?. It is PCB suppliers' duty to use international standard materials, however, too many non-standard materials appear in the global market. The supply of downstream products is scarce, leading to rising raw materials. Therefore, in order to protect their interests, some companies use A3-grade materials in private. Some companies even show customers that they use A1-grade raw materials. What problems caused when customers use A3 grade raw boards for ordinary home appliances, industrial, and automotive electronic boards? Take the LED light board as an example, LED will be short-circuited, and the light will be faulty. PCB is the carrier of electronic components and is an indispensable part of various electronic products. It is easy to distinguish that A1 grade materials are better than non-A grade materials just by considering different materials from the perspective of functional properties.

JLCPCB’s first raw materials testing video

Method 1

Preparation tools:- ? One PCB with 1.6 thickness from any PCB manufacturers

- ? A utility knife

- ? A pair of tweezers

- ? One hot air gun

Method 2

It requires a small tin furnace, but it is easier to detect. Preparation tools:- ? A PCB with 1.6 thickness from any PCB manufacturers

- ? One small tin stove

Enough PCB DIY videos? why not a PCB material testing video?

Just curious will you join in PCB raw board testing video event? People who are interested in this, please send your testing video to rebecca@jlcpcb.com. It is a hobby activity, may no bonus here. However, if there are a lot of videos received, we will make this activity big. Thanks to people who are interested and send us the video!

Tutorials

Tutorials syedzainnasir

syedzainnasir 0 Comments

0 Comments