Efficient fluid management plays a vital role in heavy industries, especially where material removal, fluid transfer, and sediment handling are required. In mining, dredging, and wastewater treatment sectors, Submersible Pumps have become essential tools due to their ability to operate directly in liquid environments. These pumps minimize the need for priming, offer energy savings, and are specifically designed to handle abrasive and solid-laden fluids. They are often integrated into solids-handling pump systems that keep operations moving efficiently in tough environments.

As industries continue to push for higher performance and lower maintenance costs, EDDY Pump stands out as a manufacturer delivering durable and efficient Submersible Pumps for tough applications. From open-pit mining operations to urban wastewater pumping solutions and offshore dredging, their pump systems are engineered to perform reliably under extreme conditions.

Submersible Pumps in Mining Operations

Mining environments are notorious for their abrasive slurries, heavy sediment, and remote locations. Traditional surface-mounted pumps often struggle with priming and clogging issues. This is where Submersible Pumps prove invaluable. Their ability to work while fully submerged allows for direct suction from the source, making them ideal for pit dewatering, slurry transfer, and tailings management.

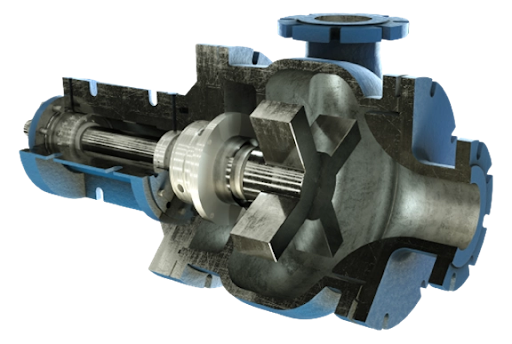

EDDY Pump manufactures heavy-duty Submersible Pumps with no tolerance between the rotor and volute, allowing them to handle large solids without clogging. This design is particularly effective in mining where rock fragments and mineral-rich sludge are commonly found in fluid streams. Their pumps not only improve uptime but also reduce the frequency of maintenance, which is critical in isolated mining operations. As part of broader industrial slurry pump systems, these units boost productivity by minimizing downtime in harsh field conditions.

Reliable Dredging with Submersible Pumps

Dredging projects—whether in rivers, harbors, or lagoons—require continuous removal of sediment to maintain navigable waterways and support construction or reclamation efforts. Submersible Pumps are a core part of modern dredging systems due to their ability to be deployed directly on the dredge head or suspended under barges.

EDDY Pump provides custom dredging solutions featuring their patented pump technology, built to transport high concentrations of solids with minimal wear. Their Submersible Pumps can move dense slurries and large particles over long distances, reducing the number of pumps required and lowering overall operational costs. The self-contained nature of these pumps also simplifies setup, making them suitable for both shallow and deep-water operations, especially as part of full-scale solids-handling pump systems.

Wastewater Applications and Industrial Fluid Handling

In the municipal and industrial wastewater sectors, managing sludge, grit, and raw sewage demands robust pumping solutions. Surface pumps often require extensive infrastructure and frequent cleaning. In contrast, Submersible Pumps streamline these processes by sitting directly in wet wells or tanks, eliminating suction limitations and reducing system complexity.

EDDY Pump offers non-clogging Submersible Pumps specifically designed for high-viscosity and high-solid content fluids, making them ideal for wastewater pumping solutions, chemical facilities, and food-processing operations. Their pumps help avoid the breakdowns and blockages common in conventional systems and support a cleaner, more efficient flow path. These pumps can also function as industrial slurry pumps in scenarios requiring solid transport with minimal disruption.

Their pumps are also compatible with existing control systems and can be automated for improved energy management and maintenance tracking.

Key Benefits of EDDY Pump’s Submersible Pumps

Across all three sectors—mining, dredging, and wastewater—EDDY Pump’s designs share several key advantages:

Solids Handling: Their open rotor design allows pumping of solids up to 12 inches in diameter without clogging.

Wear Resistance: Constructed with high-chrome and industrial-grade materials, these pumps withstand abrasive environments with minimal degradation.

No Critical Tolerances: Unlike traditional impeller pumps, EDDY’s system avoids metal-to-metal contact, drastically reducing maintenance needs.

Adaptability: Pumps can be customized for vertical or horizontal deployment, mounted on cranes, A-frames, or submersible dredge sleds.

These features make them a vital part of solids-handling pump systems and contribute to long-term cost savings.

Meeting the Demands of Harsh Environments

What separates Submersible Pumps from other systems is their ability to handle the unexpected—whether it’s sudden flooding in a mine shaft, a spike in sediment load during dredging, or a surge of industrial waste during peak processing. EDDY Pump has engineered its systems not just for average performance, but for resilience under extreme conditions.

Their continued investment in research and development ensures that their Submersible Pumps remain adaptable to evolving industry standards, from automation and remote monitoring to environmentally conscious energy use. This adaptability allows them to serve as both industrial slurry pumps and reliable components in wastewater pumping solutions across diverse environments.

Final Thoughts

As industries face increasing pressure to reduce downtime, optimize performance, and operate sustainably, Submersible Pumps have become indispensable. Whether it's managing high-solids slurries in mining, supporting efficient sediment transport in dredging, or handling untreated flows in wastewater pumping solutions, these pumps provide a practical, reliable solution.

With its unique pump design, material innovation, and commitment to customer support, EDDY Pump is helping industrial operators stay ahead in challenging fluid handling applications. Their Submersible Pumps not only meet the rigorous demands of today’s industries but also lay the groundwork for smarter, more resilient operations moving forward.

Tutorials

Tutorials xeohacker

xeohacker 0 Comments

0 Comments