Wave soldering is a widely used mass soldering process in the manufacturing of electronics, especially for through-hole elements and intricate technology printed circuit boards. In this method, a PCB is ignored, and a wave of melted solder permits solder joints to form on vulnerable part leads and pads at the same time. While wave soldering is effective and cost-efficient for high-volume manufacture, it is also liable to certain flaws if the method parameters, textiles, or patterns deliberation are not handled carefully.

Wave soldering defects in PCB assembly refer to general soldering flaws, such as spanning, defective solder, voids, and cold joints, that happen during the wave soldering process and can negatively affect the electrical execution, reliability, and long-term endurance of printed circuit boards. Wave soldering faults can compromise the electrical performance, mechanical strength, and reliability of the product. Even negligible faults, if left neglected, may lead to irregular collapses, filed returns, or breakdowns of complete products. Understanding these faults, why they happen, and how to control them is vital for quality control, process engineers, and manufacturers.

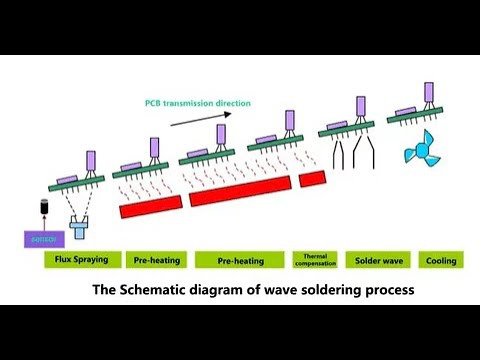

Definition of Wave Soldering Process:

The wave soldering process is a controlled series where a PCB is organised, warmed, soldered, and chilled to form powerful electrical and mechanical links between segments and the board. Before analysing defects, it is necessary to understand the basic steps of wave soldering:

- Preheating: The PCB is slowly heated to start the flux and decrease thermal shock.

- Cooling and Solidification: Solder joints cool and solidify to create endless connections.

- Flux Application: Flux is used to terminate oxides and enhance solder wetting.

- Solder Wave Reference: The board hands over one or more waves of solder.

Faults can happen at any phase of this procedure due to inaccurate temperature, inappropriate fluxing, insufficient design of the PCB, or element placement problems.

Expert’s Insight:

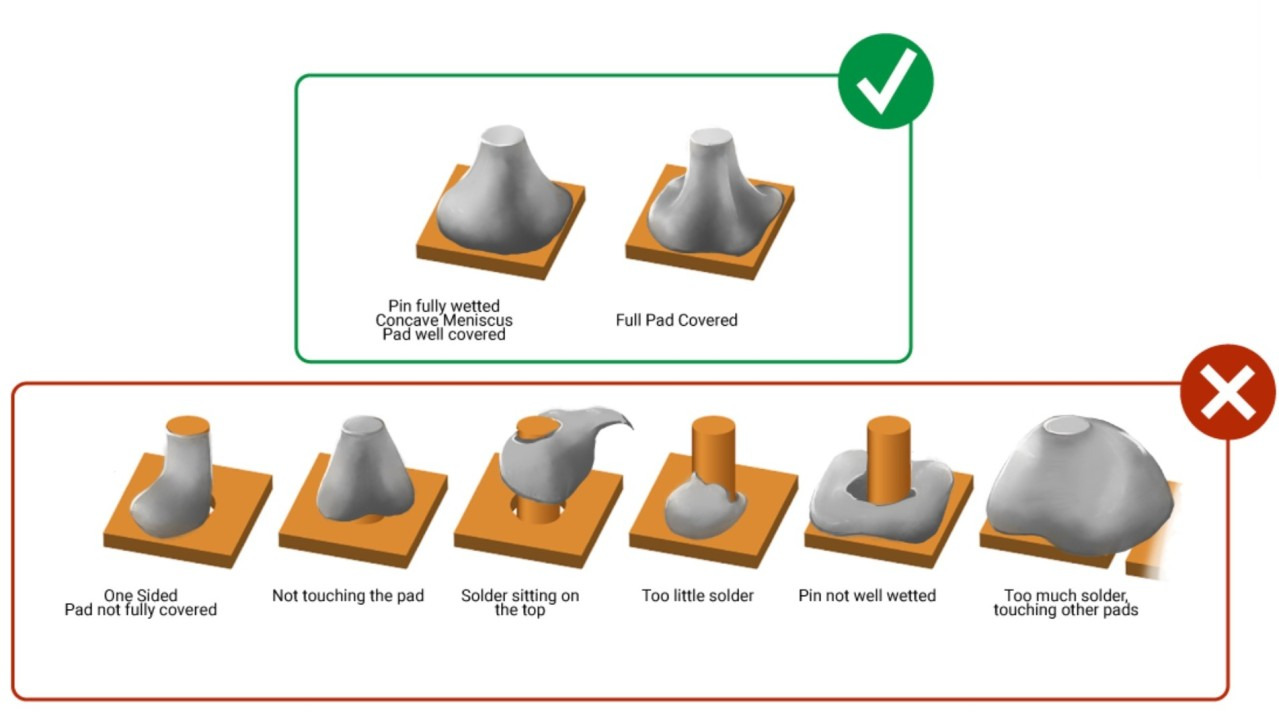

Wave soldering defects in the process… are mainly manifested as false soldering, cold soldering, not wetting, anti-wetting, poor solder joints contour shape, poor, bridging… disturbed solder joints or broken solder joints, dark solder joints or granular solder joints.”

2. Typical Wave Soldering Defects:

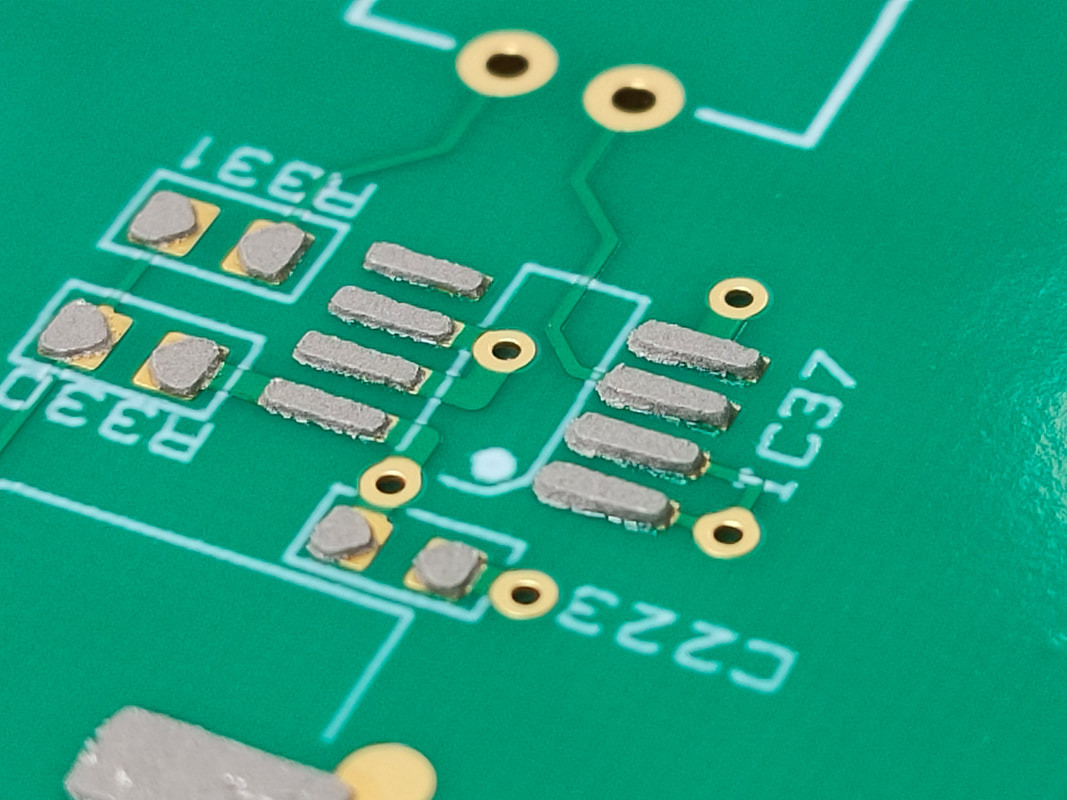

1. Solder Bridges:

Definition: Solder bridging happens when molten solder joins two or more adjoining pads or associated tips, forming an unintentional electrical short. This defect is generally caused by exaggerated solder volume, inappropriate solder mask format, low conveyor speed, or inaccurate board angle during soldering. Solder bridges can result in quick circuit failure or hidden flaws that are hard to analyse. Precluding solder bridging demands cautious optimisation of solder wave altitude, pad spacing, and solder mask range.

Causes:

- Insufficient spacing between pads

- Inadequate flux control

- Excess solder volume

- Slow conveyor speed

- Improper solder wave height

Result: Solder bridges can induce short circuits, malfunctioning circuits, or complete device collapse.

Prevention:

- Maintain correct conveyor speed

- Use selective soldering for dense areas

- Optimise solder wave height and angle

- Improve PCB pad spacing and layout

2. Insufficient Solder:

Definition: This fault happens when too little solder wets the pad or element lead, resulting in weak or insufficient joints. Insufficient solder can be caused by low solder wave amplitude or extreme conveyor speed. In many cases, insufficient solder is not readily observable during assessment, making it an effective dependability risk. Valid control of procedure parameters and surface cleanliness is important to avoid this defect.

Causes:

- Poor flux activation

- Inadequate preheating

- Low solder temperature

- Oxidised component leads

Impact: Inadequate solder joints have insufficient mechanical stability and may fail under trembling or thermal cycling.

Prevention:

- Use fresh, high-quality flux

- Adjust preheat temperature profiles

- Ensure proper solder bath temperature

- Clean and store components properly

3. Excessive Solder:

Definition: Unreasonable solder develops large joints, solder balls, or uneven fillets around segment leads. This defect is usually caused by excessive solder wave height, slow conveyor speed, or overly forceful flux application.

Causes:

- High solder wave pressure

- Long contact time with the solder wave

- Excess flux application

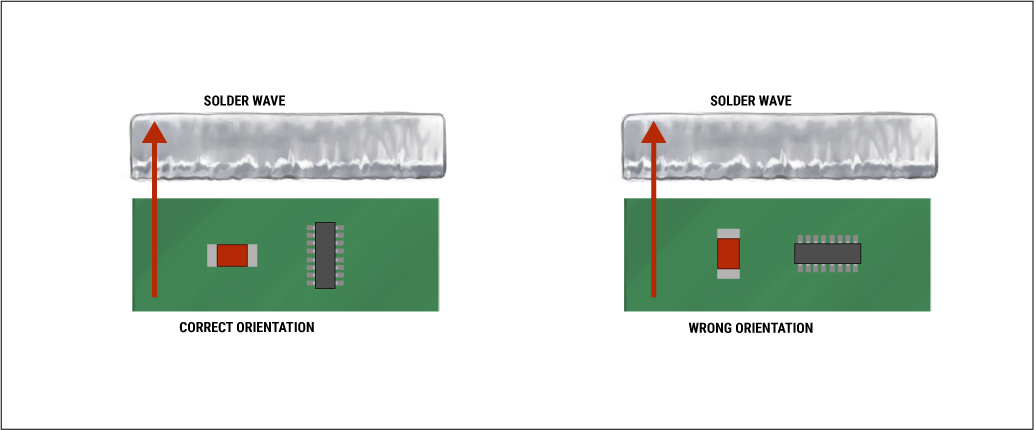

- Improper PCB orientation

Impact: Excess solder boosts the risk of bridging, consolidates assessment accuracy, and involves joint reliability.

Prevention:

- Optimise solder wave dwell time

- Maintain consistent process parameters

- Control flux volume

- Use solder thieves where necessary

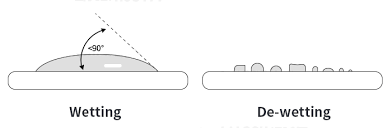

4. Non-Wetting:

Definition: Non-wetting happens when solder fails to attach to the pad or feature lead, including irregular or beaded joints. Elevated levels of environmental damage, such as sulfur or silicone, can also interfere with wetting.

Causes:

- Inactive or expired flux

- Poor surface finish on PCB pads

- Contaminated or oxidised surfaces

- Insufficient heat transfer

Impact: Non-wetted joints result in unpredictable electrical links and decreased joint strength.

Prevention:

- Maintain clean solder and components

- Optimise preheat and solder temperatures

- Use proper PCB surface finishes

- Ensure correct flux chemistry

5. Dewetting:

Definition: Dewetting happens when solder originally wets the surface but then abandons, leaving thin or irregular coverage

Causes:

- Excessive heating

- Chemical incompatibility between the solder and the pad finish

- Exterior contamination

- Offensive metallization

Impact: Dewetted joints seem inconsistent and may fail over time.

Prevention:

- Ignore overheating

- Inspect surface finishes regularly

- Verify compatibility of solder alloy and PCB finish

- Store PCBs in controlled environments

| Typical Wave Soldering and Its Causes | |||

|---|---|---|---|

| Defect type | Visual Appearance | Primary Causes | Impact on PCB |

| Cold joints | Dull, grainy solder surface | Low heat, poor flux | Weak electrical connection |

| Non-wetting | Solder does not stick | Oxidation and contamination | Open circuits |

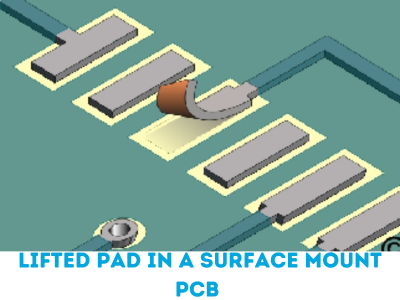

| Lifted pads | Detached copper pads | Excessive heat | Permanent PCB damage |

| Solder bridging | Unwanted solder connection between leads | Excess solder, tight spacing | Short circuits |

| Icicles | Sharp solder spikes | Improper withdrawal speed | Risks of shorts |

| Blowholes | Small cavities in the joint | Moisture trapped gases | Reduces joint strength |

6. Icicling:

Definition: Icicling directs to pointed, spike-like solder appearances developing from joints after solidification. Solder icicles are extended spikes of solder that form on the underside of the PCB as it outlets the solder wave. These protrusions happen when the solder does not cleanly separate from the joint during withdrawal.

Causes:

- Improper solder viscosity

- Poor wave dynamics

- Fast board withdrawal from the solder wave

- Low solder temperature

Impact: Icicles may break off and cause shorts or mechanical interference.

Prevention:

- Maintain proper solder temperature

- Use a nitrogen atmosphere if required

- Optimise conveyor angle and speed

- Adjust solder wave turbulence

| Prevention Techniques For Wave Soldering Defects | |||

|---|---|---|---|

| Process stage | Key control measure | Defects prevented | Recommendation action |

| Fluxing | Uniform application | Non-wetting, cold joints | Calibrate flux spray |

| Solder wave | Solder wave height | Bridging, icicles | Adjust wave pump profile |

| Cooling | Control cooling rate | Cracks pad lifting | Avoid forced cooling |

| PCB design | Proper pad spacing | Short solder skips | Follow DFM guidelines |

| Preheating | Gradual temperature rise | Blowholes, thermal shock | Monitor PCB profile |

7. Solder Balls:

Description: Solder balls are tiny, globular solder particles that attach to the PCB surface but are not part of a joint.

Causes:

- Moisture in PCB laminate

- Rapid cooling

- Excess flux residues

- High solder splashing

Impact: Loose solder balls can emigrate and generate short circuits or reliability problems.

Prevention:

- Optimise flux application

- Maintain stable solder wave conditions

- Bake PCBs to remove moisture

- Control cooling rates

8. Pin Holes and Blow Holes:

Description: These defects appear as small holes or voids in solder joints induced by trapped gases exiting during solidification.

Causes:

- Volatile flux residues

- Rapid heating

- Moisture in PCBs

- Contaminated solder

Impact: Pin holes, fatigue solder joints, and may lead to decay or intermittent failures.

Prevention:

- Use low-volatility flux

- Control heating rates

- Proper PCB drying and storage

- Maintain clean solder baths

9. Lifted Pads

Description: Lifted pads occur when copper pads detach from the PCB substrate during soldering.

Causes:

- Poor PCB laminate quality

- Aggressive flux chemistry

- Excessive soldering temperature

- Repeated thermal stress

Impact: Lifted pads often need PCB scrapping or complicated rework.

Prevention:

- Select high-quality PCB materials

- Match flux chemistry to board material

- Use controlled thermal profile

- Minimise rework cycles

10. Component Misalignment:

Definition: Components move from their planned position during soldering due to solder wave forces.

Causes:

- High solder wave pressure

- Poor adhesive curing

- Improper component fixation

- Incorrect board orientation

Impact: Misaligned components impact functionality, formation, and assessment exactness.

Prevention:

- Optimise solder wave height

- Validate conveyor alignment

- Use proper adhesives for through-hole parts

- Improve PCB fixturing

3. Effect of Wave Soldering Defects on Product Reliability:

Wave soldering defects can be instantly controlled:

- Thermal reliability

- Mechanical strength

- Electrical integrity

- Product lifespan and safety

4. Inspection and Detection Methods:

To determine wave soldering faults, manufacturers depend on:

- Automated Optical Examination

- Electrical testing

- Visual inspection

- Functional testing

- X-ray inspection

Before detection decreases rework prices and prevents inferior products from contacting clients.

5. Best Methods for Reducing Wave Soldering Defects:

- Maintain strict control over flux, temperature, and solder quality

- Implement statistical process control

- Design PCBs with wave soldering in sense

- Act on routine equipment calibration and supervision

- Train operators and process engineers regularly

Conclusion:

Wave soldering remains a critical and competent method in advanced electronics manufacturing, but it is remarkably sensitive to process deviations. Wave soldering defects, if not appropriately comprehended and managed, can especially affect the rate of production, trustworthiness, and manufacturing expenses. By recognizing ordinary flaws such as solder bridging and comprehending their core causes, producers can take aggressive measures to control them. Proper PCB design, optimized procedureparameters, quality materials, and robust assessment systems are the keys to achieving constant, high-quality solder joints. A well-controlled wave soldering method not only misjudges defects but also improves product performance, diminishes rework, and provides permanent client fulfillment.

Printed Circuit Boards

Printed Circuit Boards xeohacker

xeohacker 0 Comments

0 Comments

2.3k

2.3k

953

953

921

921

2.1K

2.1K