PWM, as the name suggests, is simply a pulse width modulation. We take a pulse and then we modulate its width and make it small or big. Another term important while studying PWM is named duty cycle. The duty cycle shows the duration for which the PWM pulse remains HIGH. Now if the pulse remains high for 50% and LOW for 50% then we say that PWM pulse has a duty cycle of 50%. Similarly, if the pulse is HIGH for 70% and Low for 30% then it has a duty cycle of 70%.

Most of the microcontrollers have special pins assigned for PWM as in Arduino UNO it has 6 PWM pins on it. Similarly, PIC Microcontrollers also have PWM pins but unfortunately, the 8051 Microcontroller doesn't have this luxury means there are no special PWM pins available in 8051 Microcontroller. But PWM is necessary so we are going to manually generate the PWM pulse using Timer0 interrupt. So, before reading this tutorial you must first read How to use Timer Interrupt in 8051 Microcontroller so that you understand the functioning of Timer Interrupt. Anyways, let's get started with the generation of PWM in the 8051 Microcontroller.

How to Generate PWM in 8051 Microcontroller ???

- You can download both the simulation and the programming code for PWM in 8051 Microcontroller by clicking the below button:

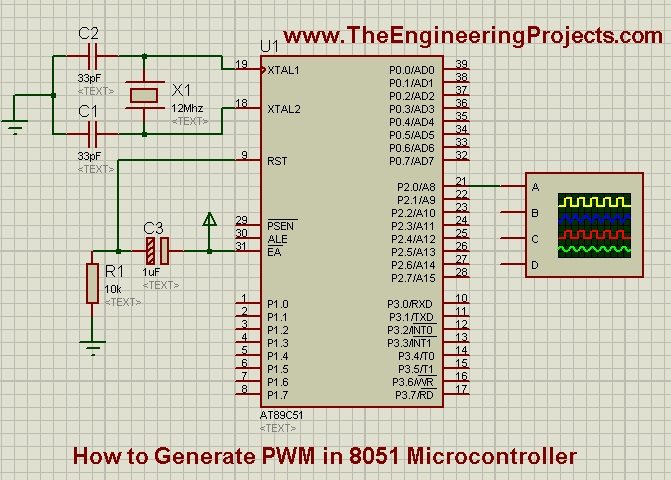

- First of all, design a simple circuit as shown in the below figure:

- Now what we are gonna do is we are gonna generate a PWM pulse using timer0 interrupt and then we are gonna send it to P2.0.

- I have attached an oscilloscope on which we can easily monitor this PWM pulse and can check whether it's correct or not.

Code in Keil uvision 3

- Now, copy the below code and paste it into your Keil uvision software. I have used Keil uvision 3 for this code compiling.

#include<reg51.h>

// PWM_Pin

sbit PWM_Pin = P2^0; // Pin P2.0 is named as PWM_Pin

// Function declarations

void cct_init(void);

void InitTimer0(void);

void InitPWM(void);

// Global variables

unsigned char PWM = 0; // It can have a value from 0 (0% duty cycle) to 255 (100% duty cycle)

unsigned int temp = 0; // Used inside Timer0 ISR

// PWM frequency selector

/* PWM_Freq_Num can have values in between 1 to 257 only

* When PWM_Freq_Num is equal to 1, then it means highest PWM frequency

* which is approximately 1000000/(1*255) = 3.9kHz

* When PWM_Freq_Num is equal to 257, then it means lowest PWM frequency

* which is approximately 1000000/(257*255) = 15Hz

*

* So, in general you can calculate PWM frequency by using the formula

* PWM Frequency = 1000000/(PWM_Freq_Num*255)

*/

#define PWM_Freq_Num 1 // Highest possible PWM Frequency

// Main Function

int main(void)

{

cct_init(); // Make all ports zero

InitPWM(); // Start PWM

PWM = 127; // Make 50% duty cycle of PWM

while(1) // Rest is done in Timer0 interrupt

{}

}

// Init CCT function

void cct_init(void)

{

P0 = 0x00;

P1 = 0x00;

P2 = 0x00;

P3 = 0x00;

}

// Timer0 initialize

void InitTimer0(void)

{

TMOD &= 0xF0; // Clear 4bit field for timer0

TMOD |= 0x01; // Set timer0 in mode 1 = 16bit mode

TH0 = 0x00; // First time value

TL0 = 0x00; // Set arbitrarily zero

ET0 = 1; // Enable Timer0 interrupts

EA = 1; // Global interrupt enable

TR0 = 1; // Start Timer 0

}

// PWM initialize

void InitPWM(void)

{

PWM = 0; // Initialize with 0% duty cycle

InitTimer0(); // Initialize timer0 to start generating interrupts

// PWM generation code is written inside the Timer0 ISR

}

// Timer0 ISR

void Timer0_ISR (void) interrupt 1

{

TR0 = 0; // Stop Timer 0

if(PWM_Pin) // if PWM_Pin is high

{

PWM_Pin = 0;

temp = (255-PWM)*PWM_Freq_Num;

TH0 = 0xFF - (temp>>8)&0xFF;

TL0 = 0xFF - temp&0xFF;

}

else // if PWM_Pin is low

{

PWM_Pin = 1;

temp = PWM*PWM_Freq_Num;

TH0 = 0xFF - (temp>>8)&0xFF;

TL0 = 0xFF - temp&0xFF;

}

TF0 = 0; // Clear the interrupt flag

TR0 = 1; // Start Timer 0

}

- I have added the comments in the above codes so it won't be much difficult to understand. If you have a problem then ask in the comments and I will resolve them.

- Now in this code, I have used a PWM variable and I have given 127 to it as a starting value.

- PWM pulse varies from 0 to 255 as it's an 8-bit value so 127 is the mid-value which means the duty cycle will be 50%.

- You can change its value as you want it to be.

Proteus Simulation Result

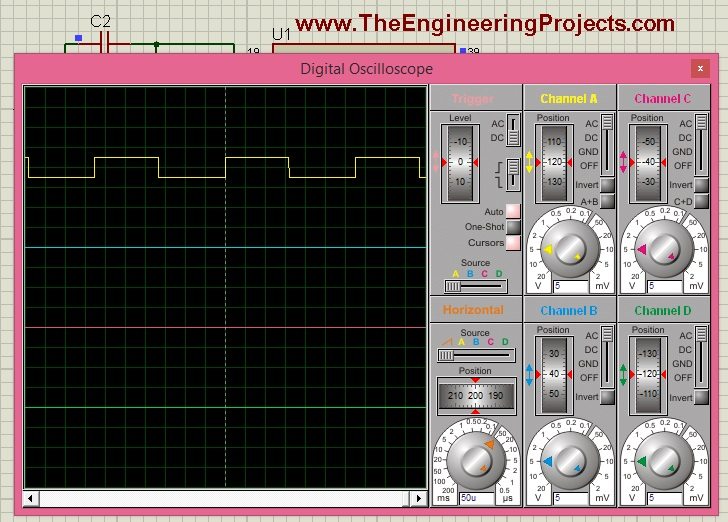

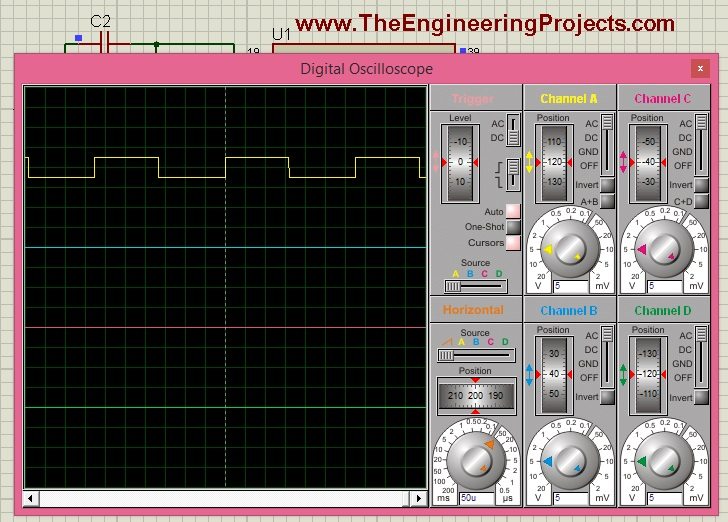

- So, now when you upload the hex file and run your simulation then you will get below results:

- Now you can check in the above figure that the duration of HIGH and LOW is the same means the pulse is HIGH for 50% and LOW for the remaining 50% cycle.

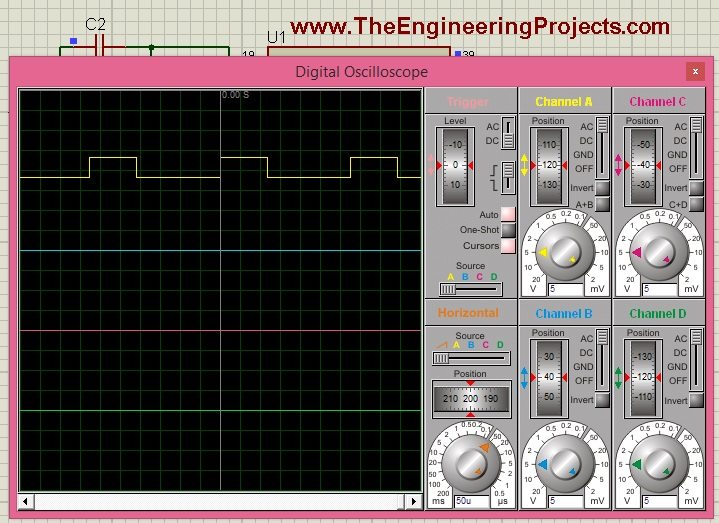

- Now let's change the PWM duty cycle to 85 which is 1/3 and it will generate a PWM pulse of 33% duty cycle. Here's the result:

- Now you can easily compare the above two figures and can get the difference. In the above figure now the duty cycle has decreased as the HIGH timing of the pulse is now reduced to 1/3 and pulse is LOW for 2/3 of the total time.

8051 Microcontroller Projects

8051 Microcontroller Projects syedzainnasir

syedzainnasir 9 Comments

9 Comments

2.3k

2.3k

953

953

921

921

2.1K

2.1K