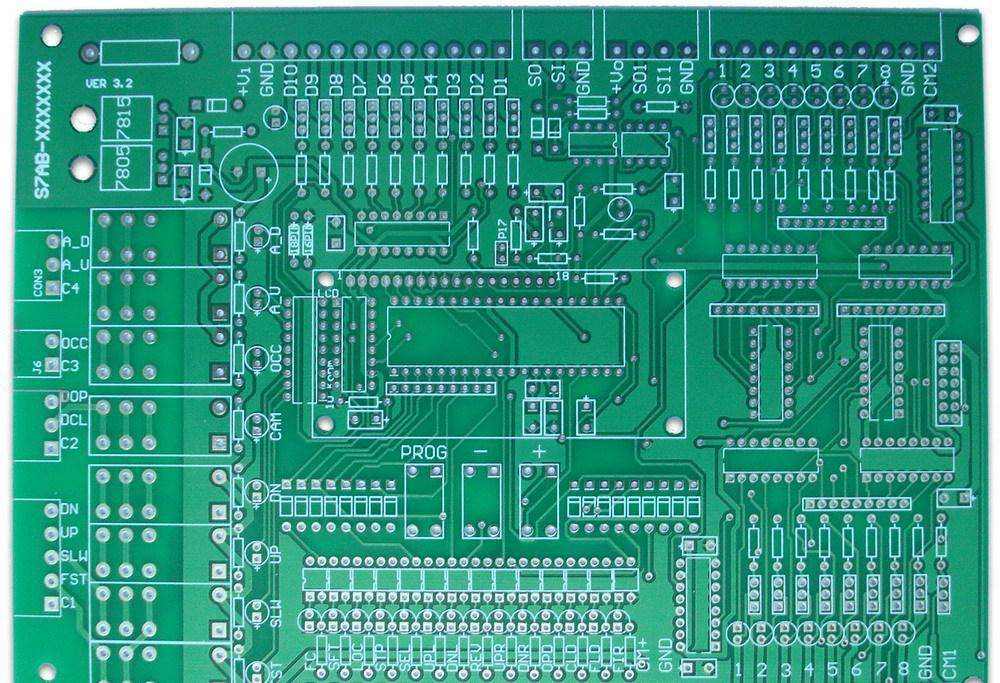

Printed Circuit Boards or PCBs are categorized into several types based on design specifications, manufacturing processes, and application requirements. They are used in various sectors such as automotive, medical, defense, and other areas, you can learn more information at PadPCB.

Before you select a PCB, there are several factors you need to consider. Moreover, it is essential to seek advice from professionals. Although there are several types of PCBs, the five standard PCBs are multilayer PCBs, Rigid PCBs, Flex PCBs, HDI PCBs, and Heavy Copper PCBs.

Common Types of PCBs

Let's have a look at the common types of PCBs:

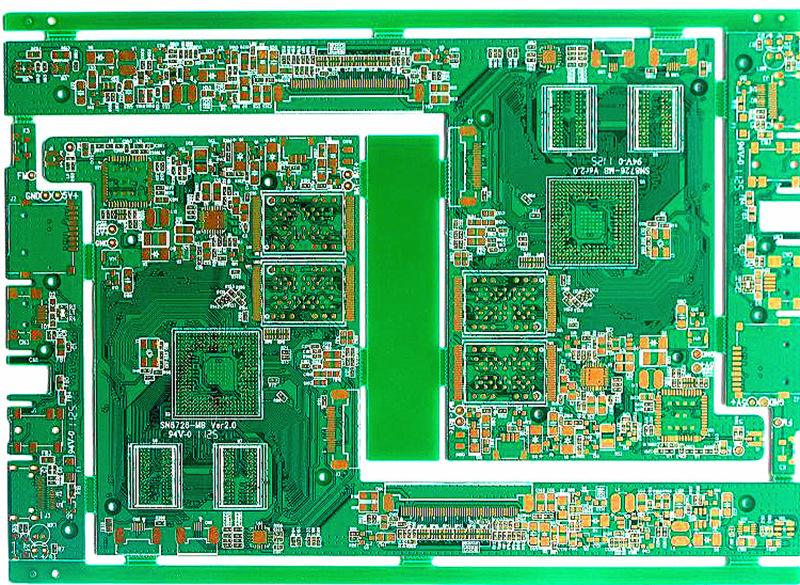

1. Multilayer PCBs

One commonly used PCB is the multilayer PCB. The board has more than two copper layers and is designed in a sandwich fashion. Also, they have many double-sided conductive layers separated by several insulating material sheets.

All are laminated and bonded together through high temperatures to ensure no air gaps occur and ensure the final PCB assembly is stable.

Advantages of Multilayer PCBs

- Compact in size – one advantage of multilayer PCBs is compressed in size. This means they can be used on numerous devices.

- More robust – multilayer PCBs are strong and are suited for extreme environments and harsh conditions.

- Suitable for high-speed circuits – multilayer PCBs are the best for devices that require high-speed circuits.

- High level of design flexibility – PCBs can be used in various sectors.

What are the applications of Multilayer PCBs?

Multilayer PCBs are commonly used in laptops, computers, tablets, smartphones, medical equipment, GPS trackers, and many other complex gadgets and circuits.

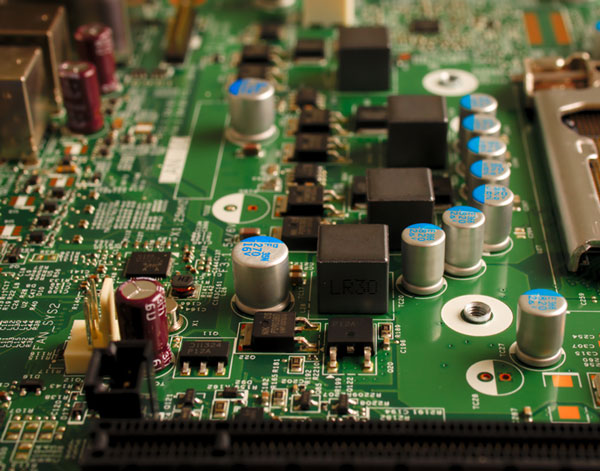

2. Rigid PCBs

A Rigid Printed Circuit Board cannot be folded or twisted. The board base is made of a rigid substrate giving it strength and rigidity.

In addition, it is composed of many layers that include a copper layer, a substrate layer, a silkscreen layer, and a solder mask layer. They adhere together with heat and adhesive.

Depending on the needs, it is possible to find single-sided rigid PCBs, rigid double-sided PCBs, and rigid multilayer PCBs. Nevertheless, once a rigid PCB has been made cannot be changed or modified.

Advantages of Rigid PCBs

- Cost-effective

- Simplicity of diagnostics and repair

- Solid

- Lightweight

- Little electronic noise

- Capability of absorbing vibrations

What are the applications of Rigid PCBs?

Rigid PCBs are commonly used in laptops, GPS equipment, computers, mobile devices, tablets, CAT scans, X-rays, heart monitors, MRI systems, control towel instrumentation, and temperature sensors.

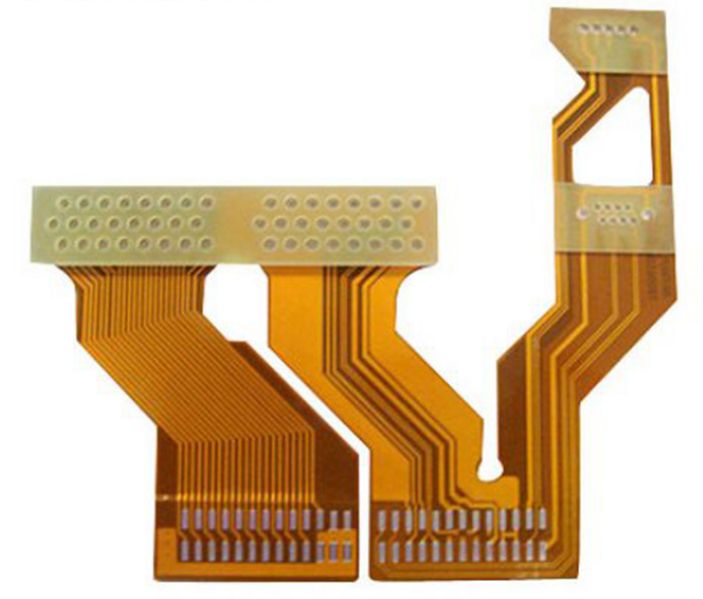

3. Flex PCBs

Flex PCBs or Flexible Printed Circuit Boards are designed with several printed components and circuits arranged on a flexible substrate. Flex PCBs are also known as flex circuit boards, flexible circuits, or versatile printed boards.

A flex PCB is mainly made from polyamide, transparent conductive polyester film, or polyether ether ketone.

They are made using the same elements as rigid printed boards. But with Flex circuits, the board can flex to your preferred form throughout the use. There are flex single-sided PCBs, flex double-sided PCBs, and flex multilayer PCBs.

Advantages of Flex PCBs

- Save space due to flexibility

- Eradicate connectors

- Increases repeatability and reliability

- Thermal management

- Suitable for various applications, especially where high signal trace density is required.

- Offer uniform electrical features for high-speed circuitry

What are the applications of Flex PCBs?

Flex PCBs are typically used in flex solar cells, LCD fabrication, cellular telephones, automotive industries, laptops, cameras, and many other devices.

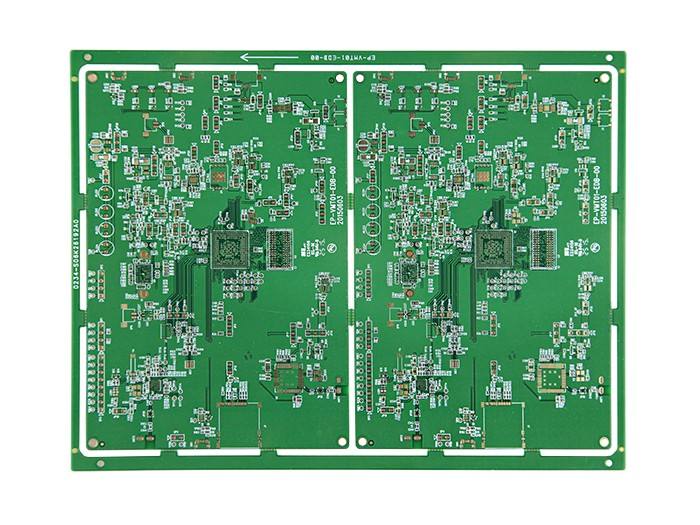

4. HDI PCBs

HDI PCB or High-Density Interconnect is a PCB with several interconnections but minimal space. The components are placed nearer, and the board space is considerably reduced, but the functionality is not affected.

Advantages of HDI PCBs

- Compact design – the combination of buried vias, blind vias, and micro vias offers the board space requirements.

- Cost-effective – the tasks of a standard 8-layer PCB are reduced to a 6-layer HDI board without affecting the quality.

- Phenomenal versatility – the boards (HDI PCBs) are perfect where space, weight, reliability, and performance are the primary concerns.

- High reliability – HDI PCBs are reliable even against extreme environmental conditions.

What are the applications of HDI PCBs?

- Medical devices - are involved in HDI PCBs because they can fit in smaller gadgets such as imaging equipment and implants.

- Automotive – HDI PCBs are the most recommended to save space in automotive. This helps in providing a better driving experience.

- Smartphones and tablets – modern smartphones are HDI PCBs. These PCBs are responsible for creating smaller and thinner electronic devices.

- Military and Aerospace – HDI is integrated into most military communication gadgets such as defense systems and missiles. Moreover, HDI PCBs are suited for harsh environments and dangerous conditions.

5. Heavy Copper PCB

Heavy copper Printed Circuit Board is also known as a thick copper PCB. It features three ounces of copper. Hence, they are highly valued due to their thermal management capabilities. Due to the increased copper thickness, the board can carry more current.

Advantages of Heavy Copper PCBs

- Increased current carrying capacity, mechanical strength, and increased thermal endurance.

- Easy incorporation with high power circuits and control circuits

- Many copper weights on the same circuitry leads to a smaller product.

- Heavy copper PCBs can withstand high thermal cycling.

- Permit the use of exotic materials to their total capacity without causing a circuit failure.

What are the applications of Heavy Copper PCBs?

Some of the applications of heavy copper PCBs are overload relays, solar power converters, power converters, weapons control systems, nuclear power applications, HVAC systems, and safety and signal systems.

Summary

PCBs have modernized the electronic industry. Today, the boards are used in almost every electronic gadget you know. However, those mentioned above are the commonly used PCBs.

If you are not sure of the best PCB to consider for your applications, make sure you seek help from an expert. Moreover, it is essential to purchasing PCBs from reputed manufacturers for commercial or industrial use.

Printed Circuit Boards

Printed Circuit Boards syedzainnasir

syedzainnasir 0 Comments

0 Comments