Hey Fellas! Welcome to our website. Today, I am going to share the 2nd chapter in the PCB learning series, where we will discuss Single-sided PCB in detail.

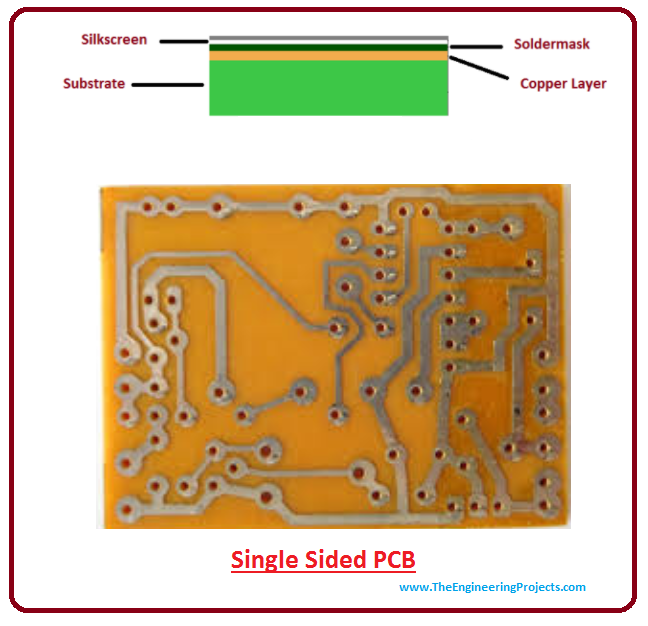

In Single-sided PCB, the copper layer is present only on one side of the PCB and the other side is used for incorporating electronic components. This type of PCB is used in simple circuits with low component density. The conductive tracks in single-sided PCB can't cross each other because of a single copper layer.

Let's dive in and explore more, I'll try to cover every aspect related to Single-sided PCB:

Single Sided PCB

- Single-sided PCB, also termed as single-layer PCB(though there's a slight difference), is the simplest type of PCB where the copper layer is present only on one side of the board while the other side is used for incorporating electronic components.

- Single-sided PCB is the simplest form of PCB and is the starting point of printed circuit board technology but still plays an important role in the electronic industry.

- These PCBs are usually cheaper to manufacture and are an ideal choice for low-density designs.

- Single-sided PCB can be designed using both Surface Mount and Though-hole technology.(We have covered in the first chapter)

- We can design single-sided PCB at home as well but it's always recommended to hire professionals for PCB designing.

Now, let's have a look at the difference between Single-sided PCB and Single-layer PCB:

Single-sided vs Single-layer PCB

- Single-layer PCB has only one layer of PCB but this layer could be single-sided or double-sided.

- In simple words, the single-layer PCB could have electronic components on single or both sides of the PCB

- Similarly, a multilayer PCB will have multiple single-sided and double-sided PCBs.

- So, we can say, a single-sided PCB will always be a single-layer PCB but a single-layer PCB could or couldn't be a single-sided PCB.(It may be a double-sided PCB)

We have studied both Single-layer and Multilayer PCB in chapter one.

History of Single-sided PCB

- Single-sided PCBs came into play in the 1950s, manufactured in the USA.

- It was produced to give components mechanical strength and a strong base with different pads and lines incorporated on it.

- In 1956, single-sided PCB took a big turn in terms of progress, when a number of PCB professionals from Japan took part in its manufacturing.

- Paper phenolic aldehyde was widely used in the early stage of the manufacturing process of single-sided PCB but soon it was replaced by glass fiber and epoxy resin because paper phenolic aldehyde exhibited bad solder thermal stability, low electric insulation, and twist issues.

- Glass fiber and epoxy resin give stability for a variety of temperature variations and it doesn't fluctuate or decompose too quickly.

Hobbyists who are highly interested in making convoluted circuit design find single-sided PCB useful as it gives them flexibility in routing and doing other things with ease like decoupling, proper ground connections and other electrical considerations. If you are an embedded geek, you should try Proteus Ares to create single-sided PCB designs.

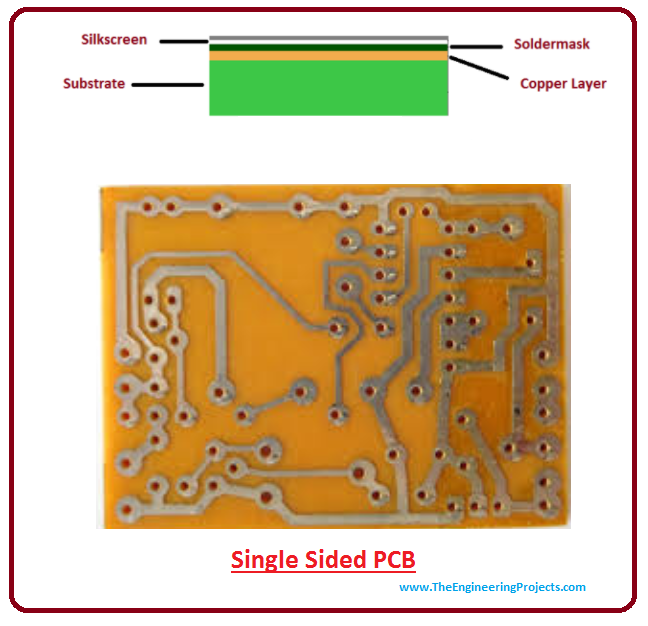

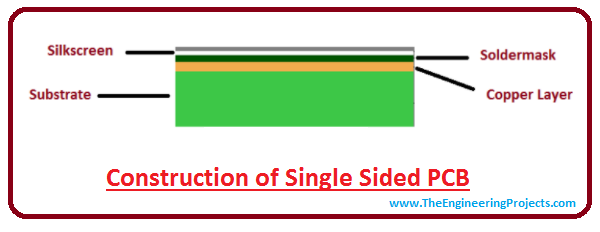

Construction of Single-sided PCB

- The base material, also named as substrate, is composed of insulating fiber glass, which gives strength and a compact look. The nature and type of base material define whether the board will be a Flexible PCB or a Rigid PCB.

- Above the substrate, there lies a copper layer, that provides conducting path for various components on the board. The copper thickness is different for different boards depending on your needs and requirements and is defined in ounces per square foot.

- On the top of copper foil, there exists a solder mask layer. This layer is mainly used for protection and makes the copper foil insulating which helps in avoiding conduction in case direct contact happens with some conducting material.

- On top of all these layers, there exists a silkscreen layer that is mainly used for adding symbols and characters on the board so a common person can anticipate a clear understanding of the board.

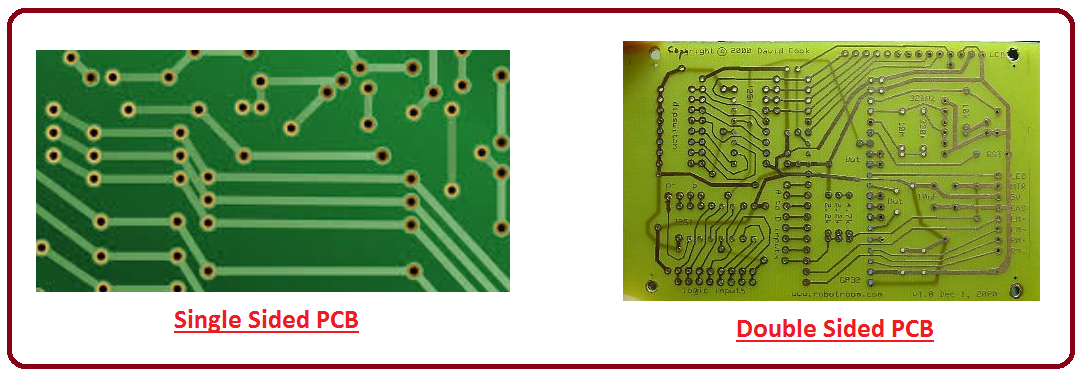

Single Sided PCB or Double Sided PCB?

- Double-sided PCB has components on both sides of the board and it normally uses surface mount technology and thus SMD components. (We will cover it in the next chapter)

- Which PCB you pick depends on your needs and requirements. Before you pick any type of PCB for your project, you must take one thing into consideration that single-sided PCB layouts are more difficult to route as compared to double-sided PCB, but the following are a few conditions where you should pick single-sided PCB.

- If you are a hobbyist or student and want to manufacture PCB at home, you must know, developing single-sided PCBs at home are much more straightforward than developing double-sided PCB.

-

Single-sided PCB is low cost. So, if you are interested in keeping your costs down, you should go for it.

- Almost all HVAC systems make use of single-sided PCBs, because they are more reliable and cost-effective and don't compromise the overall quality of the product.

Advantages of Single-Sided PCB

- It is an ideal choice for designing low-density designs.

- Highly economical in nature, makes it useful for simple electronic applications i.e. car locks, kitchen hand-held appliances etc.

- As all components are present on one side of the board, the Single-sided PCB is quite easy to debug, so if you are designing a prototype to analyze your electronic circuit, you should go for a single-sided PCB.

- It undergoes a simple manufacturing process and encounters minimal manufacturing issues, making it an ideal pick for beginners.

Applications

Single-sided PCBs are widely used in many electronic applications ranging from simple to intermediate circuits. Following are some applications they can be used for.- Vending machines

- Camera systems

- Surveillance

- Calculators

- Printers

- Solid-state drives

- Coffee makers

- LED lighting

- Packaging equipment

- Sensor products

- Power supplies

- Relays

- Radio and stereo equipment

- Timing circuits

That's all for today. In the next tutorial, we will have a look at the double-sided PCB in detail. I hope you have enjoyed the article. However, if still you feel skeptical or have any questions, you can ask me in the comment section below. I'd love to help you according to the best of my expertise. Keep your feedback and suggestions coming, they will allow us to give you quality work that resonates with your needs and expectations. Stay Tuned

Printed Circuit Boards

Printed Circuit Boards adnanaqeel

adnanaqeel 0 Comments

0 Comments