Hello everyone, I hope you all are doing great. Today, we are going to share the 9th chapter in the PCB learning series, where we will have a look at the difference between Through-hole and Surface-mount technology.

In our previous lectures, we studied both THT and SMT methods separately and have seen that both are used for components mounting on the PCB board. So, today, we will have a look at the difference between the two techniques. So, let's get started without wasting any time.

Through-Hole vs Surface-Mount

Let us know have a look at these differences and get to know the way forward when it comes to the process of component selection whether SMT or DIP.

Definition - THT vs SMT

- THT stands for through-hole technology.

In Through-hole technology, components are mounted by the use of holes that are systematically drilled through the layers of printed circuit boards. the components have long leads that are properly fitted in the holes and soldered.

- SMT method stands for Surface Mount Technology.

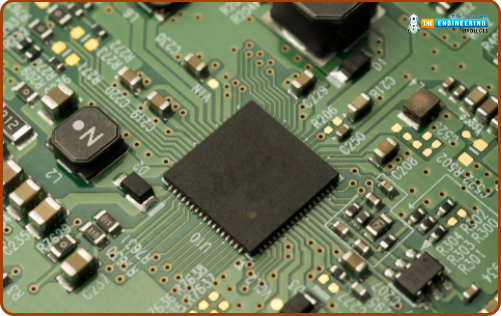

In Surface-mount technology, components are mounted on the surface of the printed circuit board. This is the most recent method employed in manufacturing of printed circuit boards.

How to Manufacture?

There are many online PCB Manufacturing companies, where you can place your SMT or THT orders. For example, let's talk about JLCPCB Fabrication House, they offer both THT and SMT fabrication. You can place your order on the official site of JLCPCB. They have an excellent support team, so while placing your order, you can discuss your design with them and they will guide you completely.

JLCPCB offers competitive prices as compared to other PCB houses and delivers quality work within the assigned time limit. They also offer seasonal discounts, so if you are a regular PCB designer, you should subscribe to JLCPCB.

Component Mounting

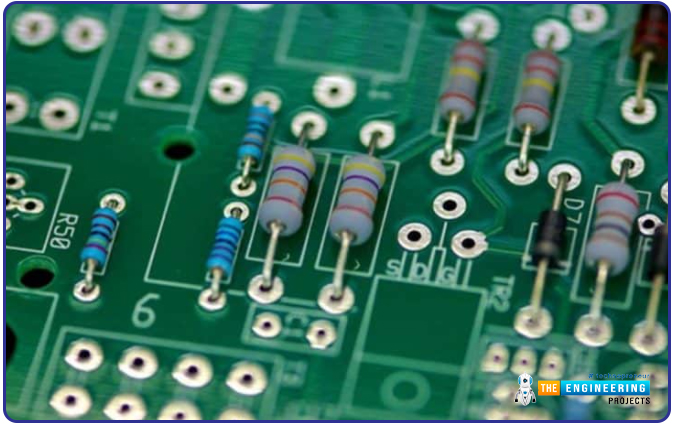

Through-hole Technology:

- In Through-hole Technology, DIP components are used having copper leads/wires called lead wire terminals.

- These leads are used to connect the components with copper tracks on the PCB board.

- These leads are inserted in the drilled holes on the PCB board and are soldered from the back side.

- The extra leads are then trimmed off using a cutter.

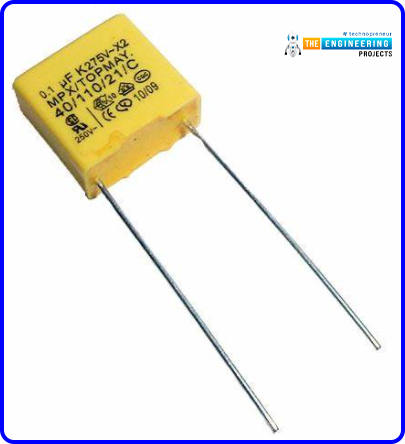

- A DIP component having two leads is shown in the below figure:

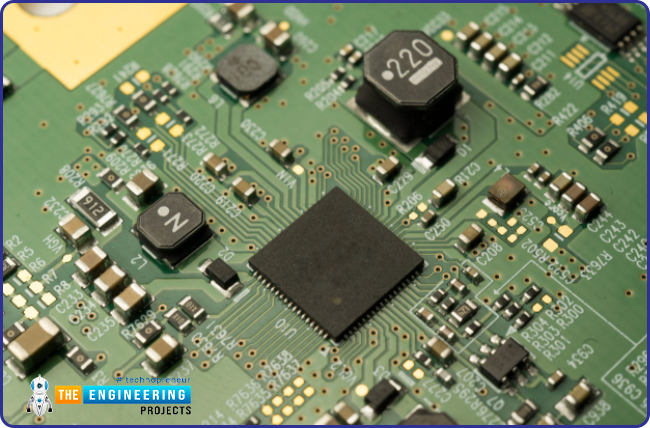

Surface-mount Technology;

- In Surface-mountTechnology, SMT components are used having copper flat terminals(called pads) instead of leads/wires.

- These SMT components are placed on the surface of the PCB board as mentioned in the design files and the flat terminals are soldered with the pads of the PCB board.

- An SMT component is shown in the below figure:

Manual vs Automatic Process

Through-hole Technology

- Through-hole PCB boards can be assembled both manually and automatically(with the help of machines).

- Normally manual assembling is preferred in THT boards.

Surface-mount Technology

- As the SMT circuits are complex in design, thus it involves the use of sophisticated systems to ensure that the process is accurate and error-prone.

- Pick-and-place machines and stencils are used in the SMT process.

- Manufacturing SMT PCB at home is too difficult so automatic processes are recommended in this case.

Stencils

Stencil is a modern technique to place solder paste on a bare circuit board. This paste forms the deposits on the board that is used to hold the components in place.

Through-hole Technology:

- The through-hole technology does not involve the use of stencils since the components are mounted in holes and are soldered on the other side.

Surface-mount Technology

- The surface mount technology uses stencils for the process to be smooth.

- Solder paste is poured through a stencil on the PCB board and then SMT components are placed on it.

Vias

Vias are small drilled holes between the PCB layers to electrically join traces of the circuitry.

Through-hole Technology

- For the through-hole technology, vias are not that necessary since the components are connected through the holes to the other layers of the boards.

Surface-mount Technology

- The surface-mount devices employ the use of the vias to connect between layers of the board. Since components are mounted on the same layer, it is very necessary to employ the vias to interconnect between the layers of the PCB board.

Debugging

- Through-hole technology mounting components and boards are quite easy to debug/repair, that's why, THT is used when a prototype or testing is required.

- Surface-mount technology components are quite difficult to debug/repair because they are very small in size.

Soldering

Through-hole Technology

- Wave Soldering is used in THT boards.

- It's an in-line soldering process that treats the solder with flux.

- The solder is melted after getting heated and then immersed on the PCB board.

Surface-mount Technology

- Reflow soldering is used in SMT boards.

- In reflow soldering, a solder paste is used to mount components temporarily on the board by the use of the pads after which the entire design is preheated.

Component Types

- Through-hole technology uses lead capacitors and resistors, DIP and GPA components.

- The surface mount technology uses LCCCP, SPOIC, QFP, BGA, SOT, LCC, chip resistors/capacitors etc.

Assembly Density

- Through-hole technology is used when a low density of components is required.

- Surface mount technology is used where a high density of components is required.

Solder Joint

Through-hole Technology

- For the through-hole technology, the solder joint connects the component lead to the board through a hole drilled on it.

- The solder is applied on the lower side of the board and the upper side is filled with the flux.

Surface-mount Technology

- For the surface mount devices, the board is first spread with the solder paste, after that components with pads are placed accordingly on the soldered points and then the solder is melted to fix the components on the board.

Cost of Production

The cost of production for the two methods varies, normally determined by the type of manufacturing process and the components used.

Through-hole Technology

- Through-hole technology proves to be the most expensive. when it comes to initial production because it involves drilling holes to mount the components.

- But when it comes to routine maintenance of the THT boards, the cost is relatively low since it is very easy to replace any component on the boards. THT is easily repairable.

Surface-mount Technology

- Surface-mount devices are cheaper when it comes to initial manufacturing.

- The process is purely automated hence saving oh human labor costs.

- Also, the process does not involve the use of holes in the mounting of the components hence reducing costs.

- The boards are produced in bulk through the process of PCB panelization, this also lowers the cost of production of the boards.

- Now, there is one challenge with this type of board, the maintenance cost is too demanding. You will need a lot of expertise to change any faulty component. Some of them cannot be changed since they are so tiny. Therefore, in most cases, if the board has a problem, you might end up buying a new one hence it is very expensive when it comes to maintenance and repair.

Applications

Through-hole Technology

- Through-hole technology is preferred in hobbyists and academic projects, because of simple circuits to design.

- THT Boards are also used in areas where strong mechanical strength is required such as in military equipment and equipment with high vibrations. This is because their soldered joints are mechanically strong.

Surface-mount Technology

- Surface-mount devices are preferred in the industry sector where commercial products are designed because SMT is cheap, lightweight and small in size.

- The manufacturing time of SMT boards is quite low, especially in mass production, because its manufacturing process is purely automated.

So, that was all for today. I hope you have enjoyed today's lecture, let me know if you need any help with it. Thanks for reading.

Printed Circuit Boards

Printed Circuit Boards zoyebella

zoyebella 0 Comments

0 Comments