Greetings and welcome to today’s lecture. Today, we are going to focus our discussion on the Surface Mount Technology of PCB components mounting. It's our 8th tutorial in the PCB learning series and is going to be a very interesting and interactive class. In Surface-mount technology, SMT components(having small pads) are placed on the surface of the PCB board and their pads are soldered on the same side of the board.

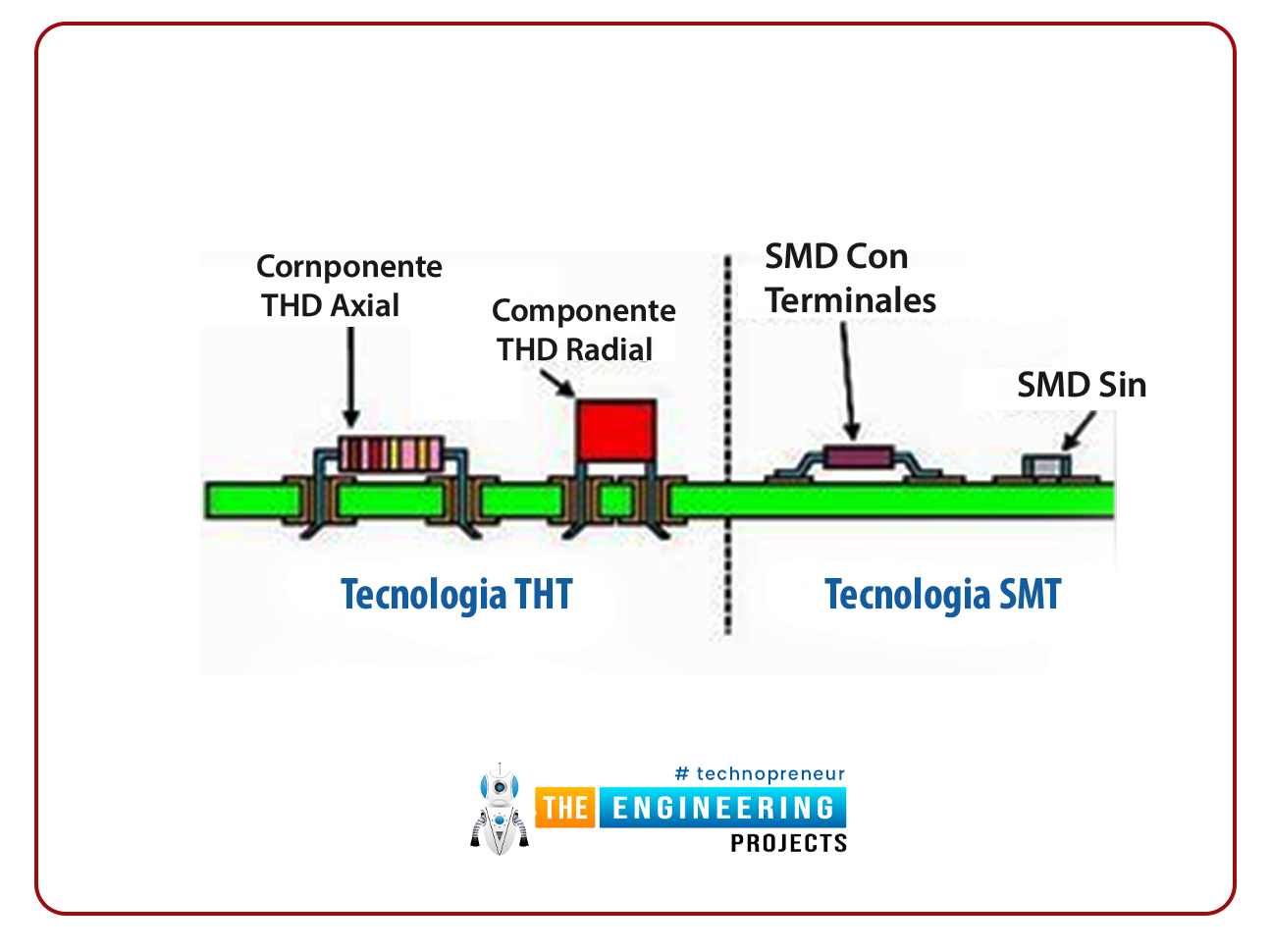

As we discussed in our last lecture on Though-Hole Technology, there are two main methods used to mount components on PCB boards. We studied THT in the last lecture and today, we will focus on Surface Mount Technology (SMT), we will discuss SMT classifications, types, applications, advantages and disadvantages in detail.

In the beginning, a breadboard was used to hold the components together. This had a major disadvantage because components could pull out as they remain loose in the breadboard, hence giving a hard time to designers, especially in the case of complex circuits. The engineers came out with a solution called the PCB board. Initially, Though-hole technology was used to plug components into the PCB board. Later on, with the invention of SMT components, surface-mount technology came into existence. So, let's have a look at SMT in detail:

Introduction to Surface Mount Technology

- Surface-mount technology(SMT), initially called planar mounting, is used to mount components on the surface of the PCB board.

- In Surface-mount technology, SMT components are used, which are quite small in size and have small pads, instead of leads/pins.

- In SMT, components are placed on the PCB board at their required positions and their pads are soldered with the copper markings on the board.

- Unlike THT, the component pins in SMT don't cross the PCB layer, they are soldered on the same side of the board.

- SMT is the most popular method that is being employed in today’s PCB manufacturing process because it can be purely automated hence increasing the number of boards produced and also saving on production time. With this method, the cost of the PCBs was reduced drastically, if you are doing mass production.

- As the name suggests, the components are mounted on the surface. So, there are no holes for the components mounting as in the THT method.

- Initially, the process was done manually but today it is done by the use of advanced machinery, thanks to the technological revolution.

- SMT discovery came in the 1980s when companies were struggling with the high demand for printed circuit boards. Fab houses had started shifting to mass production of the boards and therefore they had to introduce new methods of PCB assembly and mounting to speed up the process.

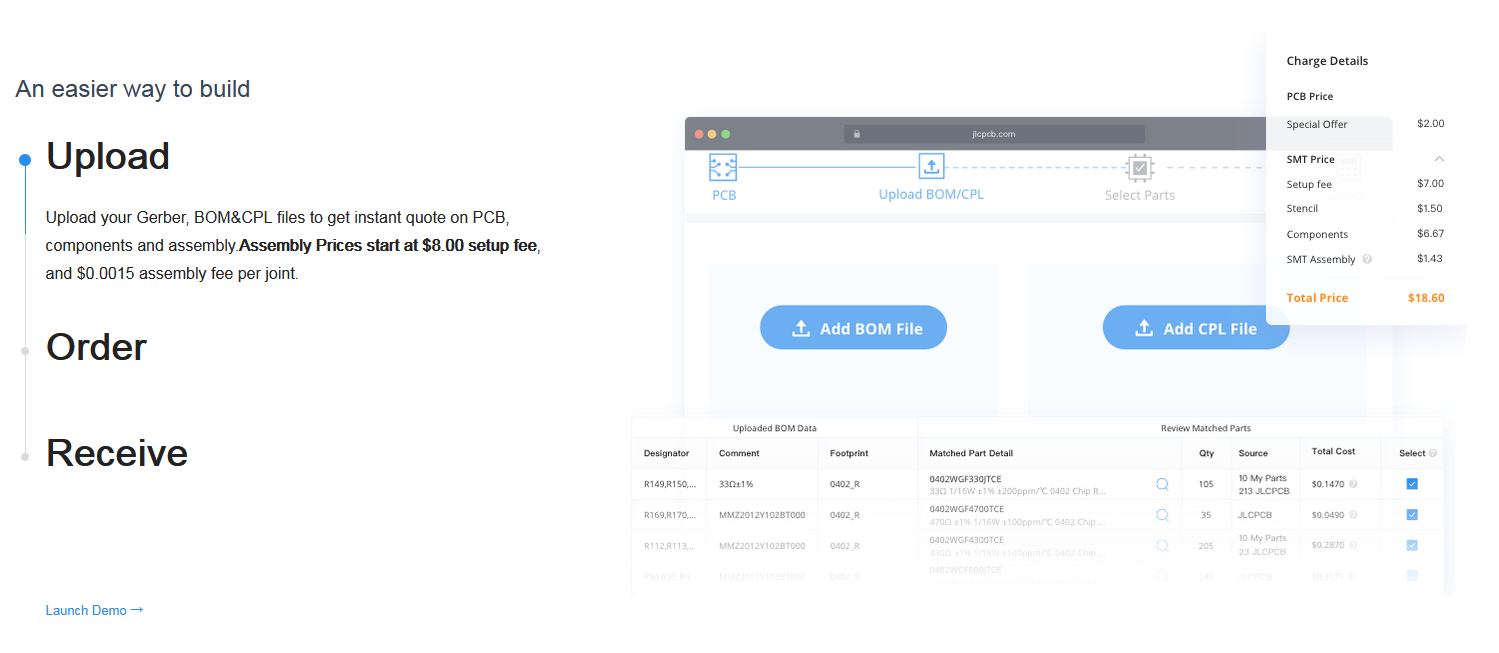

How to place an SMT PCB order?

There are many online PCB companies available, where we can place orders for PCB with surface mount technology. Let's take the example of JLCPCB Fabrication House, one of the leading PCB manufacturers, which offers top-quality products.- First of all, open this JLCPCB SMT Assembly Page.

- Here you can see, it's quite easy to place the SMT order.

- First, you need to Upload the PCB Gerber Files, as shown in the below figure:

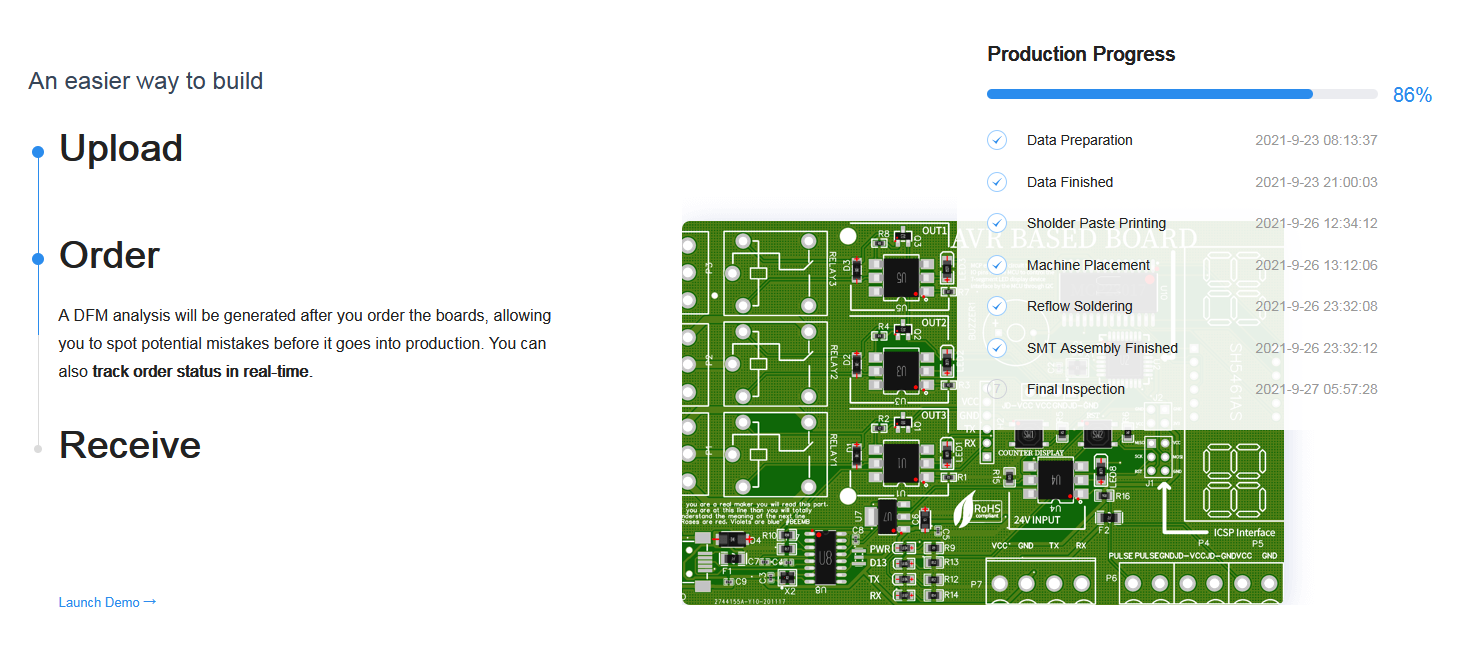

- JLCPCB has a remarkable online PCB order tracking system, which keeps you aware of the current situation of your PCB order, shown in the below figure:

- Once your SMT PCB order gets completed, you will receive it at your doorstep.

SMT Manufacturing Process

- Using the assembler, solder paste is applied on the parts where the components will be placed. The solder paste placement follows the guidelines from the design.

- Use the stencil or the solder screen to ensure that the solder has been placed in the exact required positions.

- Sometimes, stencils and assemblers might not be that accurate and it's the operator's duty to inspect the solder to ensure that it has met the required standards.

- Depending on the defect, either the assembler corrects the defect or will remove it and reapply afresh.

- The process of inspection is very important because it will determine the quality of the solder at the end of the process, hence affecting the overall functionality of the board.

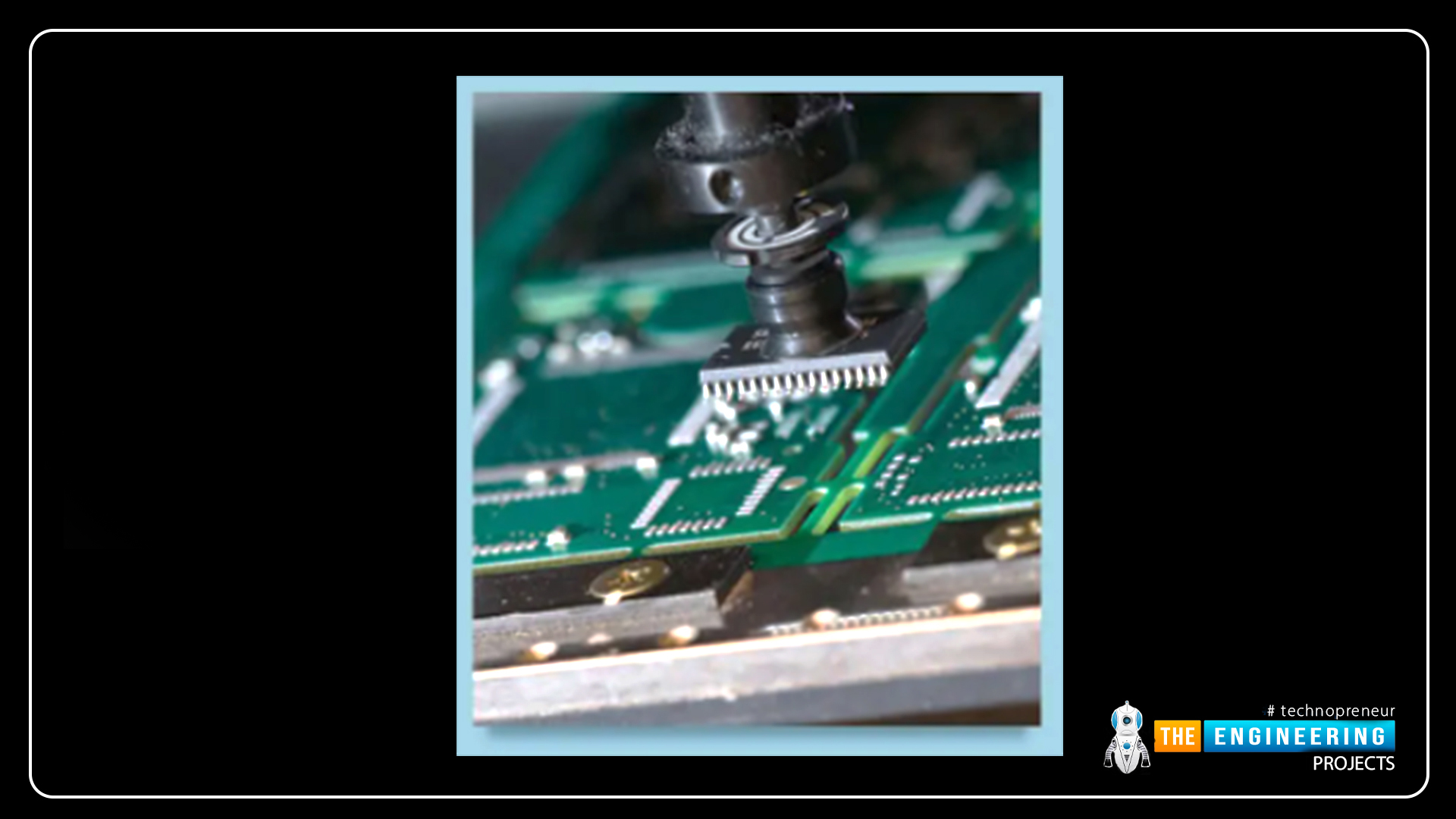

- After inspection, the assembler will place the components accurately following the designs given by the designer. Originally, it was done manually by workers with hand tools. Today, pick-and-place machines have made work quite easy, accurate, and fast.

- After placement, the components are soldered into pads with the solder gun. Here, the board undergoes a reflow process in which it is passed through the furnace to remelt, liquefy and finally solidify the solder at component joints.

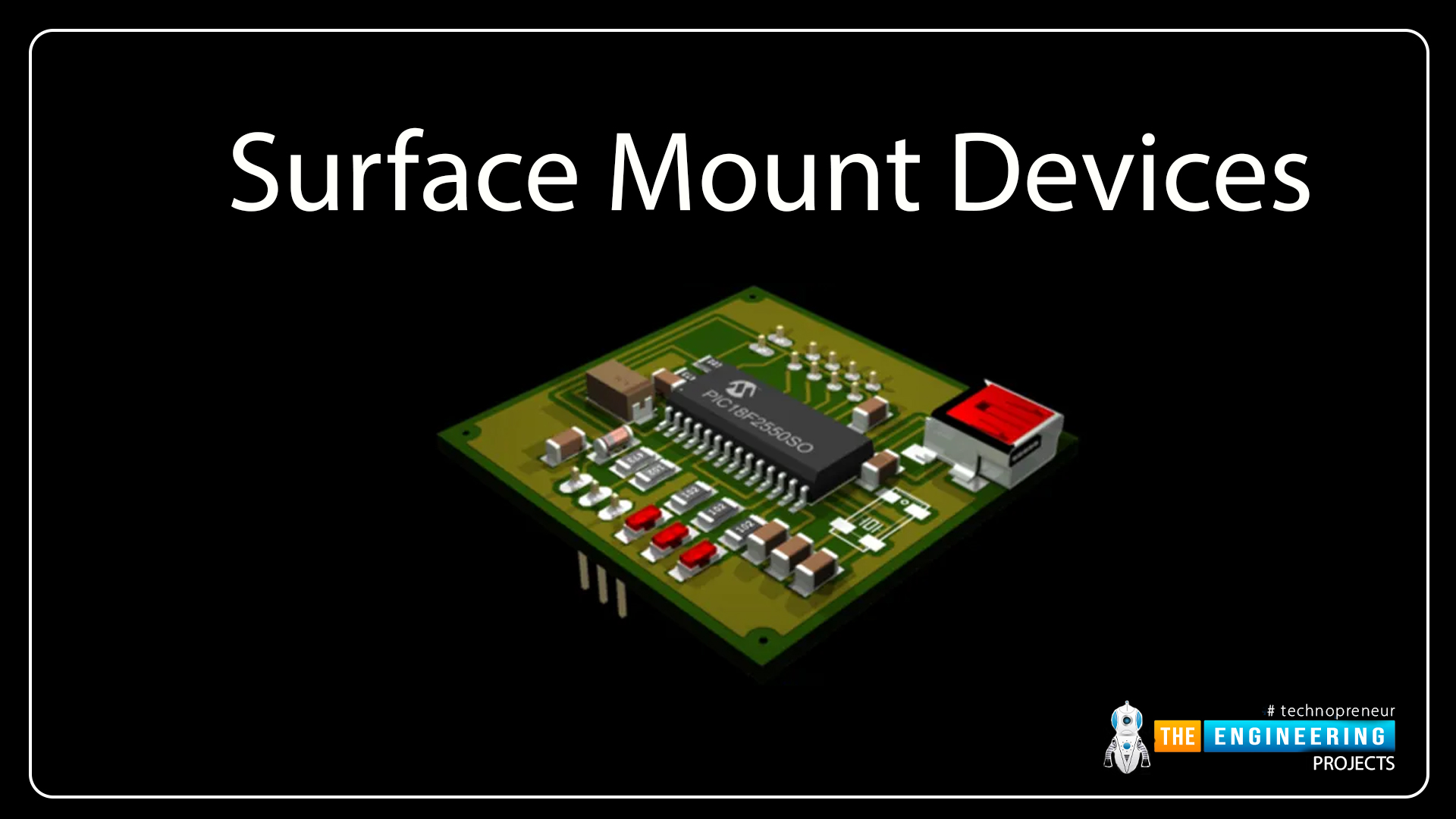

- Special devices used in the process of SMT are called Surface Mount Devices.

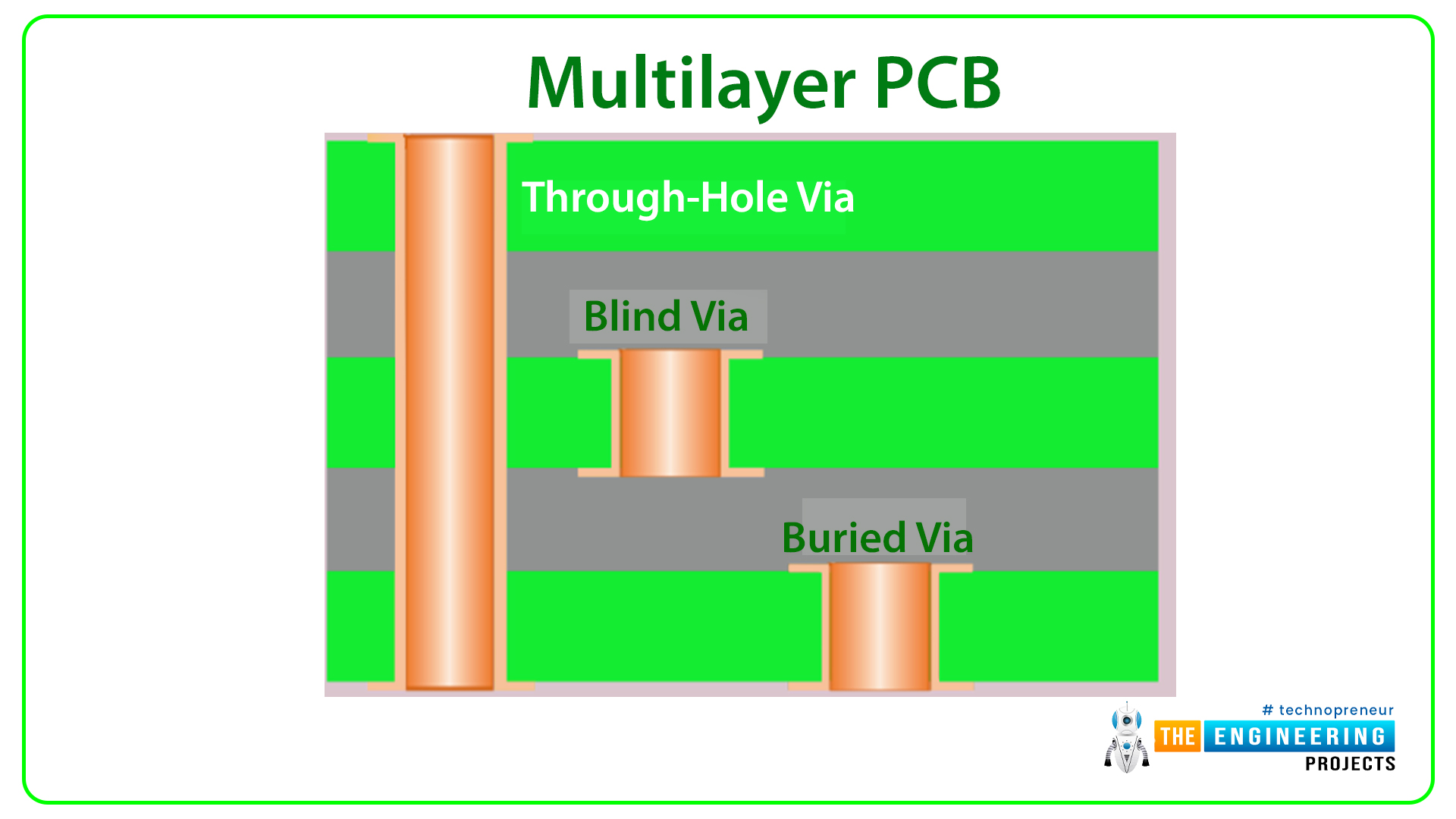

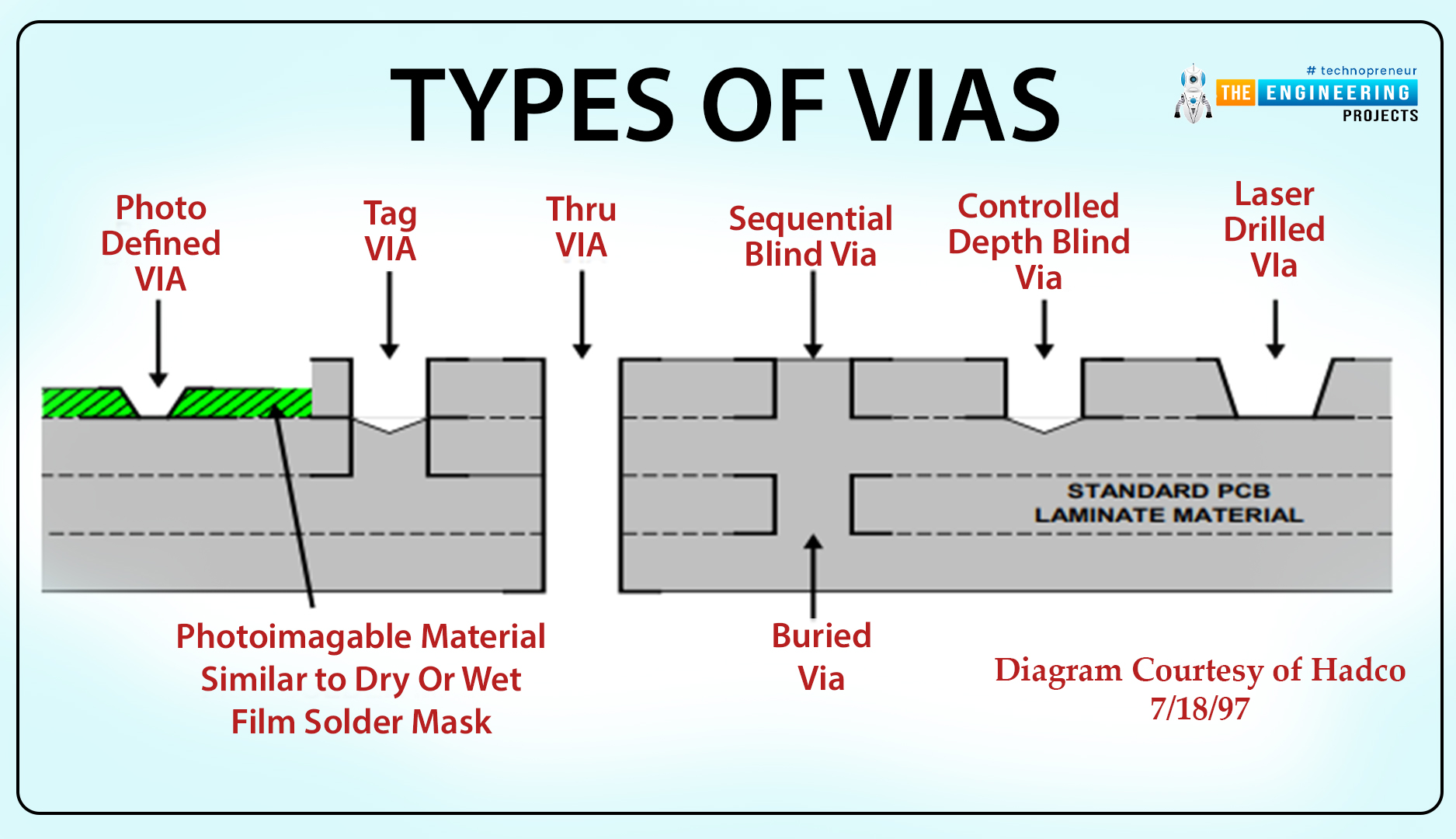

Types of vias

The SMT employs the use of vias in order to connect components with the PCB board. There are three types of vias that are employed throughout the process i.e.

- Blind vias.

- Through vias.

- Buried vias.

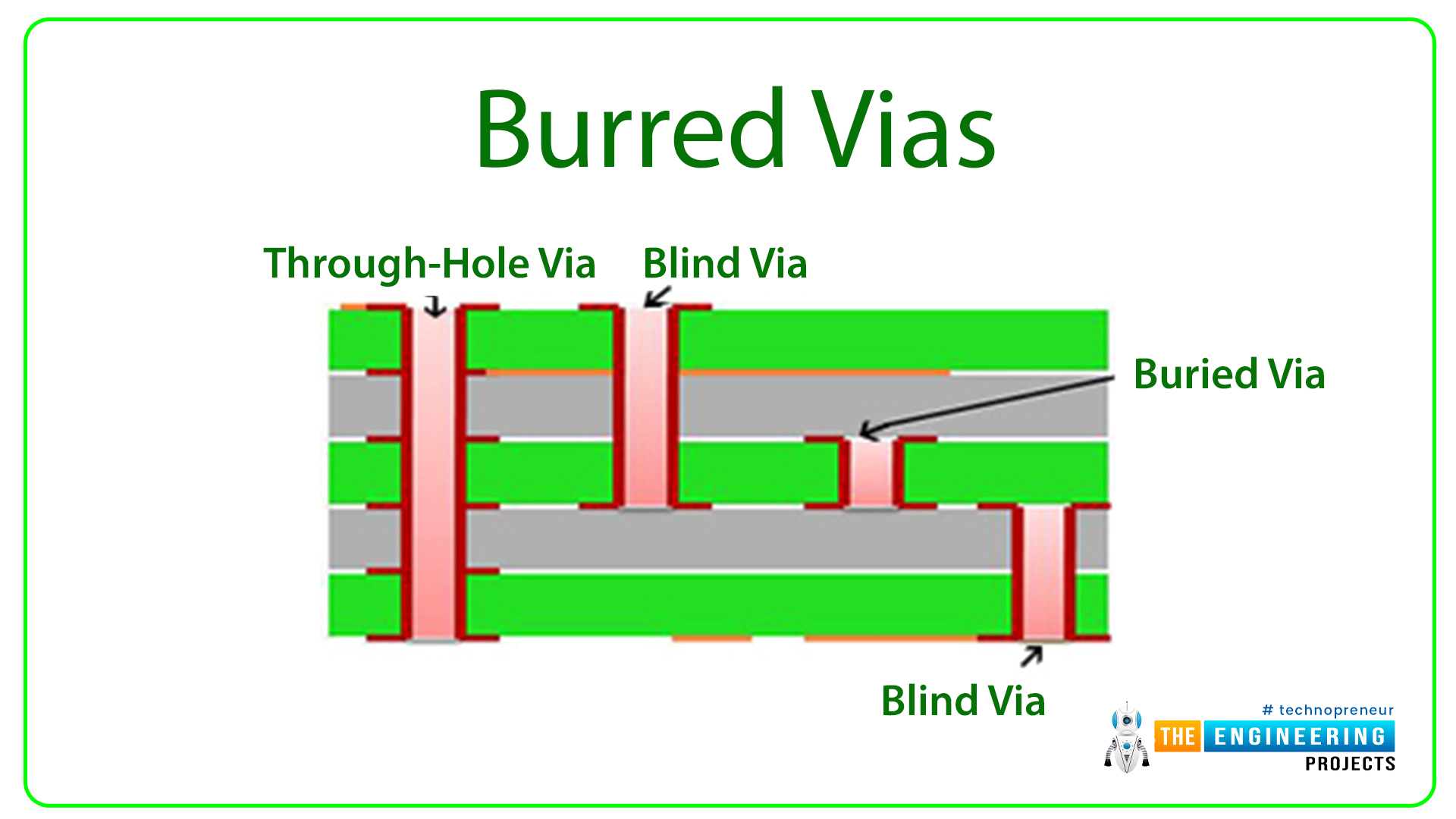

Through vias

- This one connects all the layers of the PCB board by passing through all of them.

- Mostly Through vias are used for the power pins i.e. ground, Vcc etc.

Blind vias

- Blind via connects any of the external layers to neighboring two or more layers of the PCB board but won't go through all of them(as that will be Through vias).

- Blind vias are of several types as listed below:

- Controlled depth blind via

- Photo defined blind via

- Laser drilled

- Sequential laminated blind via.

Buried vias

- Buried via connects any two or more layers of the PCB board but won't touch any of the external layers.

- As the name suggests, it remains buried inside the external layers of the PCB board.

Machines used in SMT mounting

Here's the list of machines used in the SMT manufacturing process:

PCB Drilling Machine:

- Even though I said that the SMT components are mounted on the surfaces, so there's no drilling but remember that we discussed vias, which are required to create a connection between layers of the PCB boards.

- These vias are very tiny holes drilled into the board layers and are done by the drilling machine.

Wave Soldering Machine:

- This is used for the soldering of components on PCB pads, essential for the mass production of PCB boards.

PCB Brushing Machine:

- We have discussed the vias drilling, so after the drilling process, we have debris deposited on the PCB boards.

- This debris is removed by the PCB brushing machine.

Pick-and-Place Machine:

- Pick-and-Place Machine picks up the components, rotates them in the required direction and places them on the PCB board.

PCB cleaning machine:

- It does all the necessary cleaning of the board.

- It also ensures that the board is dry and free from any form of moisture.

Reflow oven:

- It contains a lot of burners and is used to smooth the soldering process.

- There are three types of Reflow ovens available:

- Vapor Phase Oven.

- Infrared Oven.

- Convection Oven.

Now, let's have a look at the different types of Surface Mount Methods:

Types of Surface Mount Technology

Type I

- Only SMD components are found in this type of PCB board.

Type II

- Active surface mount devices and DIPs are located on the primary side of the PCB while the surface mount chips are on the secondary side of the board.

Type III

- In this type, you will find passive SMCs on the secondary side of the board while the primary side is made of the DIPs only.

- It contains only discrete mount components and they are all mounted on the bottom side.

- The discrete components include; transistors, resistors, capacitors etc.

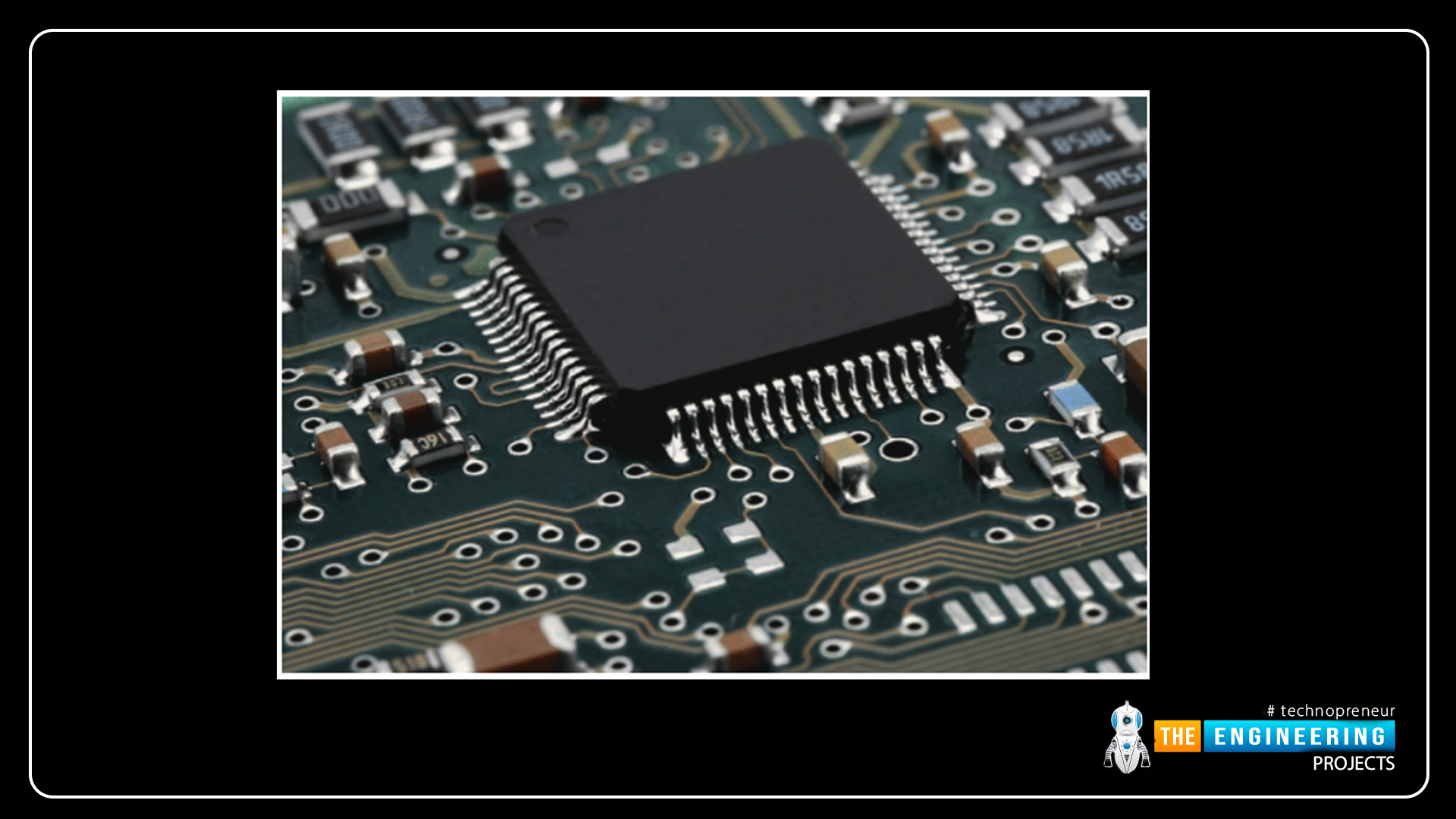

Applications of the SMT components

With SMT technology, it has become possible to produce

very compact and small-size boards, since machines are used to pick and

place the components. Therefore, SMT technology has numerous applications in real-life fields, few are as follows:

- Smartphone Evolution: Smartphone boards are quite small in size but complex in design because mobile phones need to be thin and light therefore, this technology has aided a lot in the evolution of the smartphone industry.

- Computer and laptop motherboards: It has helped in the production of ultrathin laptops, tablets and computers.

- IoT Devices: With SMT technology, IoT has moved to another level since the production of embedded boards become easy and fast.

- Involved in the manufacturing of communication and telecommunication equipment i.e. Bluetooth, WiFi, Ethernet devices etc.

- Medical devices in aid of health screening.

- Finds applications in the transport area i.e. drones, space exploration equipment etc.

Advantages of the SMT components

- They have very low RF interference

because they don't have leads.

- It takes lower packaging materials and this is due to the advanced manufacturing that is being involved.

- If SMT boards are produced in panels(We will cover penalization in upcoming chapters), the process makes it easy to transport in bulk at a reduced cost.

- The production cost has been drastically lowered compared to that of the THT product of the equivalent magnitude.

- Component failure is very low due to the consistency of the fabrication process involved.

- Less expensive process and very economical due to the use of more advanced technologies like PCB Panelization and pick and placing mechanism.

Disadvantages of the SMT components

- It is not the best method to mount high-wattage components because such components dissipate a lot of heat that may end up damaging the PCB board.

- This is made up of very tiny components and therefore if there is any damage to the circuit, it is very complex to repair/debug the board as compared to the THT components. This means time-consuming in repairing and also very expensive.

- This type of board cannot be used in a place where rough holding is involved.

So, that was all for today. I hope you have enjoyed today's lecture. In the next lecture, we will have a look at the difference between these two mounting techniques i.e. THT vs SMT. Till then, take care. Have fun !!!

Printed Circuit Boards

Printed Circuit Boards zoyebella

zoyebella 0 Comments

0 Comments