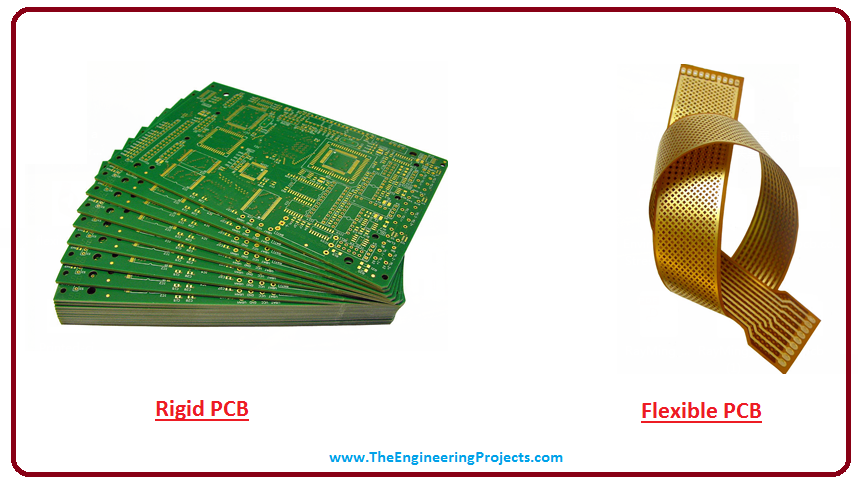

Rigid PCB

Rigid PCB

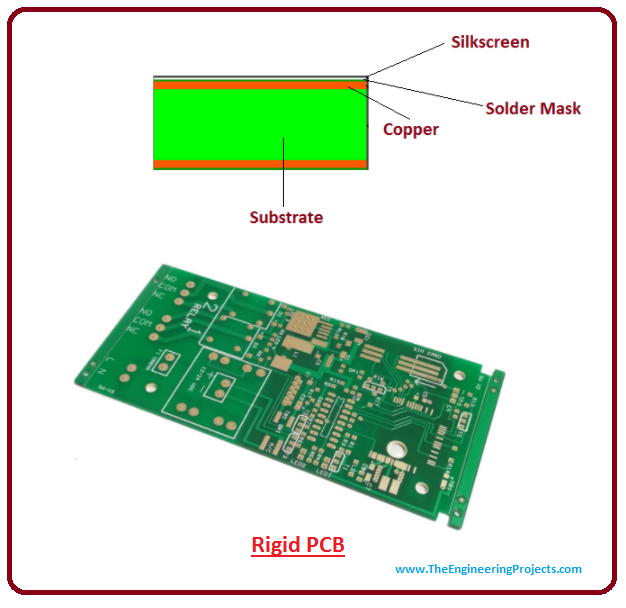

- Rigid PCB is a type of regular PCB which can not be twisted or folded into any shape because it comes with FR4 stiffener which is very useful for added amount of stiffness and rigidity.

- Rigid PCB is made up of copper trances and paths which are incorporated on a single board in order to connect the different components on the board. The base material of the board is made of rigid substrate which gives rigidity and strength to the board.

- Computer motherboard is an ideal example of rigid PCB that comes with rigid substrate material.

- Once the rigid PCBs are manufactured they can not be modified or folded into any other shape.

- Rigid PCBs are cheap as compared to flexible PCBs. They are traditional forms of PCBs and widely used in many electronics products.

- In terms of ease of use and availability, both flexible and rigid PCBs come with own limitations and benefits and both are used to connect multiple electronic components on the board.

- If you are planning to design PCB then you should have a look at these Top Online PCB Design Services.

- There are also different software available which can be used to design these PCBs, for example:

- Altium

- Proteus

- EasyPC

- I personally use Proteus software and I have also shared PCB Designing in Proteus ARES.

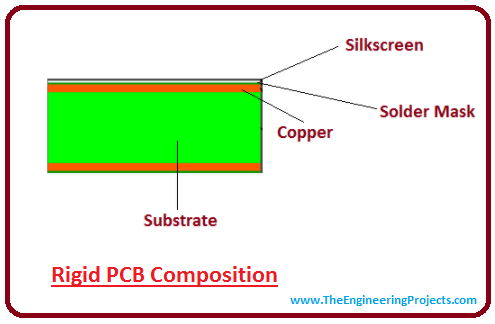

Composition of Rigid PCB

Rigid PCB is made up of different layers that are joined together using adhesive and heat, providing a solid shape to board material. Following layers are used to develop a rigid PCB.Substrate Layer

- Substrate layer, also referred base material, is made of fiber glass.

- The FR4 is mostly used as a substrate material which a most common fiber glass that provides rigidity and stiffness to the board.

- Phenilcs and epoxies are also used as a base material but they are not as good as FR4, however, they are less expensive and feature unique bad smell.

- Decomposition temperature of phenolics is too low that results in delamination of the layer if solder is placed for long duration of time.

Copper Layer

- On the top of substrate layer, there resides a copper foil which is laminated on the board with the help of added amount heat and adhesive.

- In common use, both sides of the board are laminated with copper, however, some cheap electronics come with only one layer of copper material on the board.

- Different boards come with different thickness which is described in ounces per square foot.

Solder Mask Layer

- Solder Mask Layer houses above the copper layer.

- This layer is added on the board to add insulation on the copper layer in order to avoid any damage in case any conduction material is touched with the copper layer.

Silkscreen Layer

- Silkscreen layer is located above solder mask layer.

- It is used to add characters or symbol on the board that provide better understanding of the board.

- White color is mostly used for silkscreen however, other colors are also available including grey, red black and yellow.

Comparison between Rigid And Flex PCBs

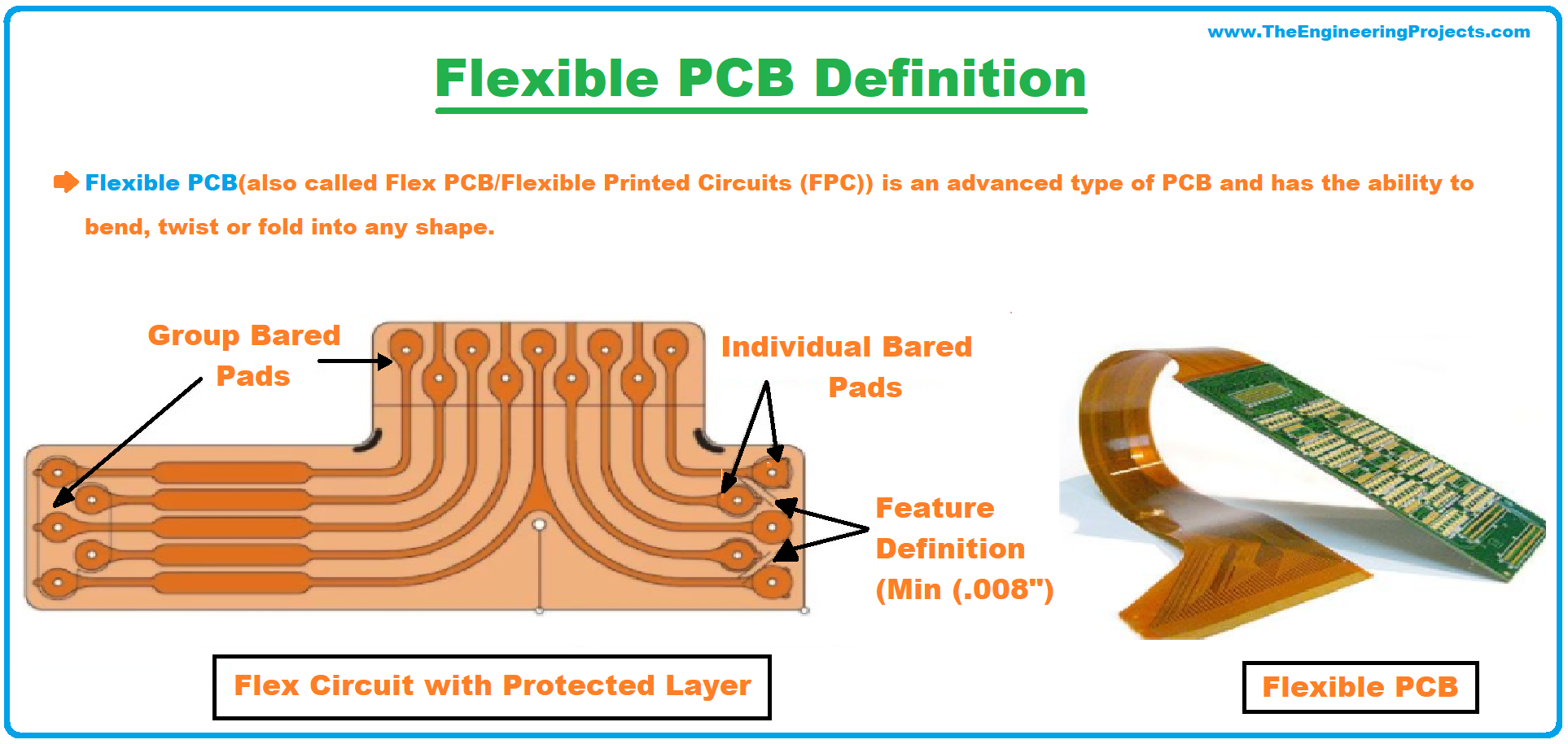

- Most of the electronics made use of traditional rigid PCB. However, technology has been evolved and many products abandoned rigid PCBs because of their inability to get folded or twisted. This has erupted the idea of flexible PCB and soon it became the prerequisite for most of the professionals in the market.

- Manufacturing process of both rigid and flexible PCBs is same with some exceptions in terms of their flexibility, softness and cost.

- Some extra measures are required for processing flex PCB when it comes to material handling. Also proper specifications are required in order to avoid any cracked solder joints when the board is bent.

- Flexible PCBs are most costly than rigid PCBs, however, we are referring here individual cost of the flexible PCB, it may happen the overall cost of the project using rigid PCB is higher than the cost of the flexible PCB, but individual cost of flexible PCB will be higher.

- Many cheap electronics make use of rigid PCBs including audio keyboards, desktop devices, solid state drives, toys and many electronic gadgets. However, flex circuits are observed in ultra high performance device because they don't involve connectors also thinner than rigid boards and can be used in smart phones, cameras, tablets and GPS control system.

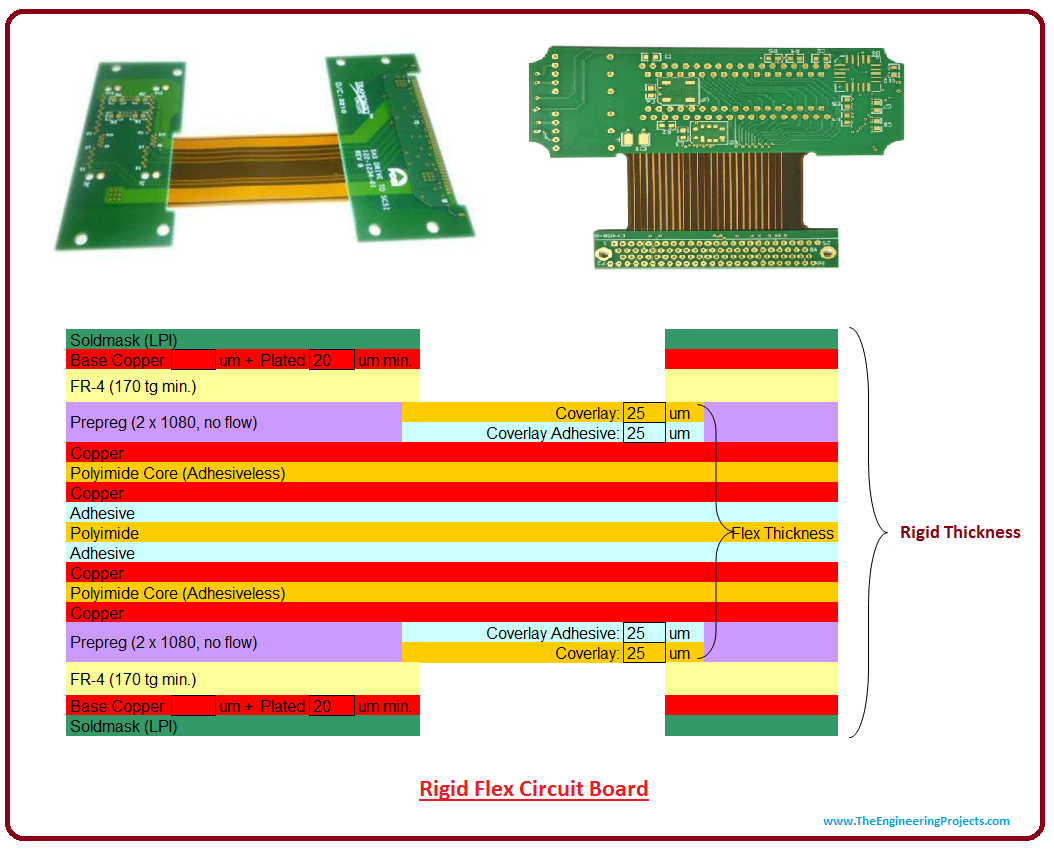

- Both rigid and flexible boards can be incorporated together to construct a unified product that comes with both strength and flexibility.

- Some flex PCBs follow the same design as rigid circuit design but they are not completely identical to the rigid circuit boards.

- Flexible PCBs provide flexible and bending solutions and they also require less space and are mostly Single Sided PCB.

Applications

- A computer motherboard is a perfect example of rigid PCB which is a Multilayer Rigid PCB, used to distribute electricity from power supply, and creates a conducting path between CPU, GPU and RAM.

- Rigid PCBs are manufactured in volumes and once they are designed, they can not be altered or modified and remain same throughout the entire life span of the project on which they are placed.

- Some low cost products make use rigid PCBs like toys, ,electronics gadgets, desktop devices and solid state devices.

- You should also have a look at Double Sided PCB, these are also Rigid PCBs.

×

![]()